- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Looking Back: Tapping and threading

110 years of Canadian Metalworking

- By Canadian Metalworking

- July 2, 2015

- Article

- Cutting Tools

As we continue celebrating the 110th anniversary of Canadian Metalworking magazine, in this issue we take a look at the state of metalworking technology 110 years ago with a focus on tapping and threading.

In 1905, several companies introduced new products and machinery developments, as well as advertised the latest and greatest innovations.

Here is a look at just a few of the latest technologies of 1905.

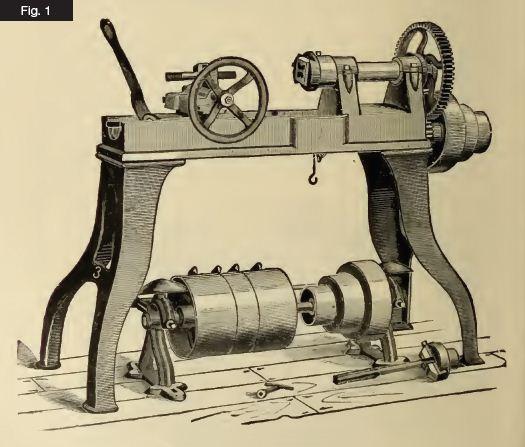

BOLT AND NUT MACHINE

Boynton & Plummer of Worcester, Massachusetts, introduced its Bolt and

Nut Machine.

“The accompanying image (fig. 1) illustrates an extremely useful machine…for threading bolts and tapping nuts.”

According to the article, this machine can be built in several sizes, either for hand or power but can be configured for both a hand and power combination.

“It is claimed that with these machines larger-sized bolts can be threaded with greater ease and facility than with any other similar make, while small sizes can be cut as rapidly as with a small machine.

A very desirable feature of these machines is that they are constructed to accomplish the work intended with the least number of parts to get out of repair, of any tool of its kind.

With these machines they furnish taps and dies for rough iron sizes, that is, 1-32 large and V thread. Either solid or adjustable dies are furnished as desired.”

In 1905, Boynton & Plummer also manufactured a complete line of machines for blacksmiths, carriage-makers, repair and machine shops, such as drills, forges, tire benders, tire shrinkers, bolt heading machines and shaping machines.

“They are receiving constantly testimonials from users of their machines all over this country and foreign lands, of which volumes could be made, as to the reliability and general satisfaction of the output of their work.”

Boynton & Plummer was incorporated in Maine in 1909 with William J. H. Nourse as president. However, in 1918, the company was then incorporated in Vermont under the leadership of John A. McGuire. Boynton & Plummer struggled through the Depression and eventually dissolved in the 1940s.

Boynton & Plummer produced metal working machinery including drilling machines, shapers, and bolt threaders in addition to wood working machinery, including planers, jointers, shapers, and saw tables.

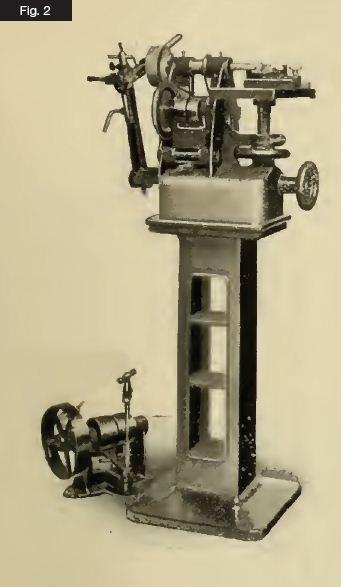

TAP AND DIE GRINDER

Greenfield Machine Company of Greenfield, Massachusetts, also developed its latest machine, the Tap and Die Grinder.

“A recent product…is a tap and die grinder embodying new features (fig. 2). The tap-sharpening attachment consists of two centerheads mounted on a swinging arm, which carries the tap across the face of the cup emery wheel.”

A description of the Tap and Die Grinder is as follows:

“The arm swings at an angle with the face of the wheel, permitting the tap to be ground at any angle. The tap is indexed by means of a rigid tooth rest and held in place on centres, one of which is attached to a spring lever, allowing the tap to be removed quickly. Means are provided for holding a tap, which has the end broken off, or one without centre holes as shown in the image.

The work is brought towards the wheel by means of a hand wheel at the front of the machine. Chucking reamers can also be ground on this fixture. Will hold from 3/8-inch hand taps to 1 ¼-inch machine taps.”

For a look at more tapping and threading products, check out our our cutting tool feature on page 54.

The Greenfield Machine Company’s Tap and Die Grinder was featured in 1905; however, the company focused not only on their product but also able quality assurance standards when it comes to threads, explaining that “Small Instruments of Measurement” work best for measuring threads.

Never before have engineers and mechanics possessed such a wealth of measuring instruments as they have at their command today…The problem met with in very fine measuring instruments are far from being new, but their applications to engineers’ tools is mainly a development of the present generation.

The place of gauged measurement is that of fixed and unalterable dimensions often repeated.”

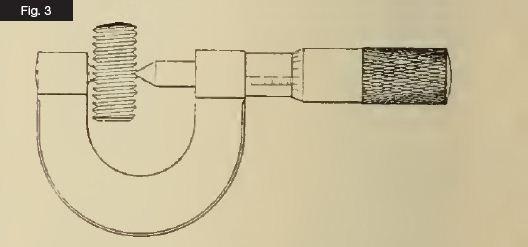

Thread Measurement

When it comes to measuring threads on screws today, there are many different products available for various features. In 1905, one of the popular products was a special micrometer caliper.

“This image (fig. 3) shows a special form of the micrometer caliper used for screw gauging. It is more delicate than the ring gauges used for a similar purpose, because it does attempt the almost impossible task of perfect contact all round the circle and at all sections of the thread.

The points and roots of threads do not affect the result, since measurement is taken down the sides and one-half the depth of the thread.”

For a look at different tools for internal and external thread measurement, check out our quality feature on page 90.

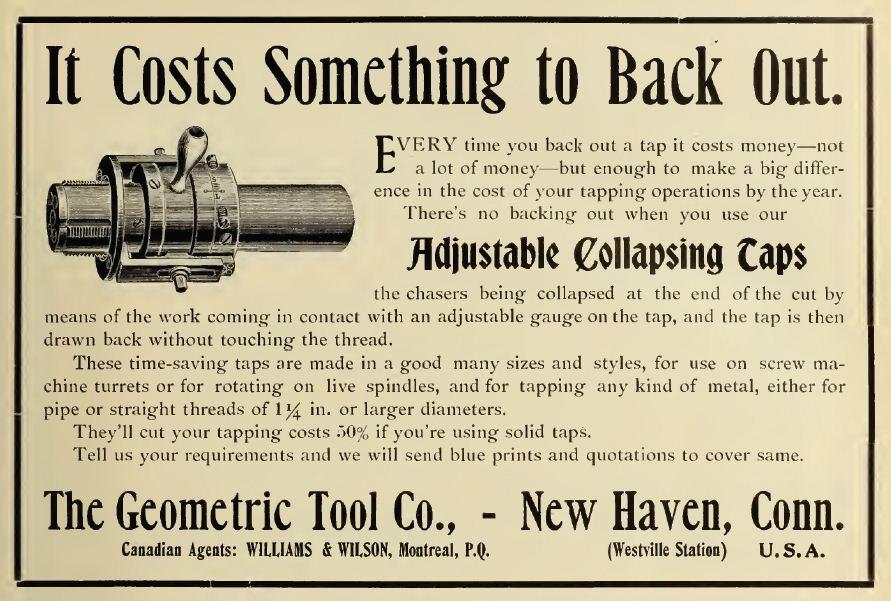

1905 Tapping Advertising

Here is advertisement from The Geometric Tool Co. of New Haven, Connecticut from 1905.

This company was promoting its adjustable collapsing taps for tapping of metal, either pipe or straight threads of 1-1/4-inch or larger diameters.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI