- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Business Profile: Build-A-Mold

Bringing a production mentality to a custom mold shop in Windsor, Ontario.

- By Canadian Metalworking

- January 25, 2016

- Article

- Metalworking

Build-A-Mold, of Windsor, Ontario decided the company motto for 2014 would be ‘change.’

“One of the core challenges we were facing was how to apply a production system to our custom mold shop,” says Rob Caixeiro, moldmaker manager at Build-A-Mold (BAM). “We wanted to find better ways to open up capacity on a CNC machine and improve our EDM workflow by replacing our outdated equipment. We needed to understand how high-performance equipment would fit our needs and help us change our shop.”

Caixeiro led the capital investment project and he and his team spent a lot of time reviewing machinery and automation and analyzing the anticipated paybacks. They found their solution in several high-performance machines spanning from horizontal mills with automation to high-precision 3- and 4-axis vertical graphite mills with automation and a large 6-axis horizontal mill, all from Makino. In just over a year, the shop floor at BAM transformed, along with the business’ overall efficiency, capacity and profitability.

“We have seen a 70 per cent increase in production and efficiency in our mold inserts, thanks to the higher RPM and reduced monthly tooling cost generated from our new equipment,” says Caixeiro. “We are using this newfound capacity to expand the business and to capture additional revenue opportunities from repeat work.”

A Strong Presence

BAM got its start in 1978 with just two employees in 2,000 square feet of rented space. Today it has 110 employees in Windsor and serves as a “one-stop shop” to the plastics industry—handling part design and concept, machining, plastic injection molding, assembly, painting, chroming and shipping finished parts to customers. The OEMs it works with include Chrysler, GM, Toyota and Honda. Owned by A.P. Plasman, the company has production in Windsor and Alabama. In its other locations in Canada, Michigan, Wisconsin and Japan, it is able to focus on steel cores and cavities and small parts.

BAM has a strong presence in the Windsor moldmaking market due to its reputable performance and service. The company’s decision about which equipment to purchase was driven by its desire to compete with the offshore market. Caixeiro and the BAM team spoke with other moldmaking companies in the Windsor area to find out what kind of equipment they were using.

“When doing research on equipment, we like to get feedback from the people actually using the machines,” he says. “We wanted equipment that is well known and that already has a footprint in this area.

“People around here are very forthcoming about sharing their positive experiences. As a result, we don’t feel like we are competing with each other, but we are competing with companies overseas.

“In our research with our peers, Makino’s name kept coming up. Not only is their [Makino’s] equipment used at the majority of area operations, but their reputation and local service from SST-Canada are also highly regarded.

“I had experience with the company from a prior job, and we saw the equipment in action at IMTS 2012. All of these factors caused us to choose Makino. We knew we could start producing quality parts right away. We feel that you get what you pay for. This is a solid product that can produce without any issues. We have confidence in its reliability.”

In total BAM purchased five new Makino machines in 2014: the F3 and F5 vertical machining centers with robotic automation system to use in its graphite electrode production; an MCC2013-VG 6-axis horizontal machining center for its large mold finishing; two a61nx horizontal machining centers and the MMC2 automated 12 pallet-handling system for small-mold components

In addition, BAM purchased the FCS clamping system for the MCC2013VG and a61nx machining cells in an effort to reduce setup times and adapt to a production mindset.

“SST’s Tony Facione was a huge support in helping us identify the equipment that would suit our needs,” says Caixeiro. “During the installation of our equipment, we sent many of our operators to training in Auburn Hills, Michigan and Mason, Ohio. We knew there would be a bit of a learning curve, especially going from the vertical machining centers to the horizontal equipment. Our employees embraced this change.”

Improving Efficiencies

The new robotically automated F-Series cell, which includes the F3 and F5 with a rotary table, has helped BAM to improve current electrode production efficiencies by eliminating costs, increasing machine utilization, improving quality, and enhancing the flexibility of EDM workflow scheduling.

When it comes to production efficiencies, the company used to have a backlog cutting graphite, but the new equipment has allowed it to open up capacity and take on more work.

“Before getting the F-Series cell, we relied upon outsourcing $150,000 in electrode production with our five older VMCs,” says Tony Couto, EDM supervisor at Build-A-Mold. “Now we can perform all of this work in the cell with fewer machines, and operators can be redeployed into more value-added roles around the shop. We’re talking some huge savings. Less capital consuming floor space, less labor time spent babysitting machines, lower maintenance, less energy consumed around the clock, fewer fixtures, less tooling—the list just goes on. We have one operator loading the cell to max capacity, and the machines just keep cutting. It’s that simple.”

According to the company, the electrodes being produced today are high quality, and previous issues, such as graphite dust pollution, are eliminated, thanks to the machine being designed for graphite machining.

“This investment has allowed us to cut more detailed and complex electrodes faster,” says Couto. “We can use smaller tools and attack the part from the sides. This has helped us increase our efficiencies.”

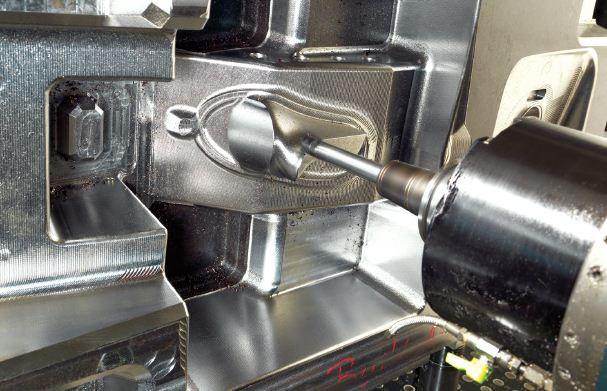

Efficiencies were also realized with the addition of the MCC2013-VG. The company is experiencing added versatility with multiple axes and can shorten tooling, eliminate multiple operations and remove more material, especially on larger blocks with this machine.

“With the MCC2013VG, we can cut bigger blocks because the equipment’s spindle will rotate, picking up a larger machining envelope,” says Dave Ives, senior CNC technician at Build-A-Mold.

“We can get everywhere we need to be, including hard-to-reach areas, and the quality coming off of the machine is phenomenal. We have brought the finishing operations of large molds back in-house and are achieving greater quality than ever before. We are achieving tool blends of 0.0005 inch and parting lines of 0.001 inch, leading to a 70 per cent reduction in secondary grinding operations and cutting time from fitting and spotting.”

Costs are saved not only in secondary operations but also in tooling.

“Investments in advanced technology have led to a 40 per cent reduction in tooling expenditure,” says Billy Ayres, CNC operator at Build-A-Mold. “Quality of work has been night and day, with tolerances all in spec. We no longer have to put all of our focus on how we are going to cut something. The new equipment has opened up our options. We don’t have to second-guess what we are going to do.”

Operators no longer worry about working around the limitations of their previous machines or babysitting them to control errors. The machines just run.

“After installation of the MCC2013-VG, we immediately started accomplishing our goals,” says Caixeiro. “It ran unattended that first week and hasn’t stopped. It has replaced seven older 3- and 5-axis machines while simultaneously increasing capacity, improving quality and reducing lead-times. Our new challenge is optimizing processes to utilize the full capabilities of the MCC2013-VG and its horizontal work orientation. We feel that this machine can help us become more competitive and win more business.”

BAM has had equally positive results with its a61nx cell. The company is able to mill rib features that would have previously required EDMing.

“The a61nx cell has cut lead-times in small mold components by as much as 50 per cent,” says Joe Hindi, CNC supervisor at Build-A-Mold. “The flexible scheduling capabilities have enabled us to hit or surpass the timelines given to us.”

The company is not only meeting shorter lead times in small mold components but has also opened up revenue opportunities for repeat work.

“When we went to training in Mason, they told us that the a61nx cell would be one of the best workers that BAM would ever see,” says Hindi. “They were right. It’s smart enough to know where it has left off, and it feeds itself without stopping. It’s a great machine.”

FCS Adds to Production Transformation

The addition of the FCS clamping system on both the a61nx cell and the MCC2013VG has also contributed to changing BAM into more of a production operation.

“The FCS has been the perfect sidekick to the Makino equipment,” says Keith Andreoff, senior CNC technician at Build-A-Mold. “Operators estimated that the use of FCS has reduced setup times by an average of 50 per cent by eliminating the need for manual indicating of fixtures and components.”

The system helps BAM be more flexible by helping it adjust to new builds and engineering changes.

“We notice that everything is operator-friendly. With the FCS you don’t have to put much thought into it. The software knows where the FCS is and where the component is, and you just cut, knowing what the outcome will be. Before, we worried about how we would hold something, and we had to tweak things to get it close. Now we get it perfect,” says Andreoff.

Between the FCS and its new high-performance equipment, BAM has evolved its custom mold shop into more of the production operation it desired. It can run the machines around the clock with less indirect labor cost, greater reliability and improved quality.

Change for the Better

All of these changes have enabled BAM to focus on what matters most to the company: the quality of the products, its customers, employees and stakeholders. Investments in technology have been a crucial step in making all this happen.

“We aimed for ‘change’, but I think ‘transformation’ is a better word to describe our business over the last year,” says Caixeiro. “From the way we order materials to how we process work and manage on-hand inventory, we’re operating more efficiently, more profitably. But most importantly, we’re now able to provide customers better quality workpieces and shorter lead times with greater reliability, and at a lower cost to boot. By creating greater efficiencies and cash flow throughout other segments of the business, BAM has also become a more highly valued asset within our parent company, A.P. Plasman.”

Throughout these changes, BAM remains dedicated to producing quality parts at competitive pricing, always on time, for its customers. These customers are excited about what the company is doing, especially the fact that it is staying ahead of the curve through this change.

“Customers have confidence in us,” says Caixeiro. “They have taken notice that we are supporting them through our investments. They have shown their appreciation by placing more orders with us. Outsourcing has been reduced by 70 per cent already with our additional capacity. Our initial return on investment projection is already ahead of schedule and is anticipated to happen in just two years. Based on this success, we plan to purchase additional equipment.”

BAM’s operators, who no longer have to work 60 hours a week to finish a project, also approve of the new equipment.

“Everyone is pleased with the change that has occurred due to the performance of the machines,” says Caixeiro. “The equipment has allowed us to improve our morale and our results. Employees come to work happy and confident in the business because we’ve invested in state-of-the-art equipment and their training on industry-leading technologies. We want them to go home feeling they’ve accomplished something, because that makes us happy. We wouldn’t be able to do all of this without our high-performance equipment.”

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI