- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Visualize Getting More From Existing Equipment

Dashboard analytics can increase uptime—and profits—in any size shop

- By Sue Roberts

- September 15, 2016

- Article

- Metalworking

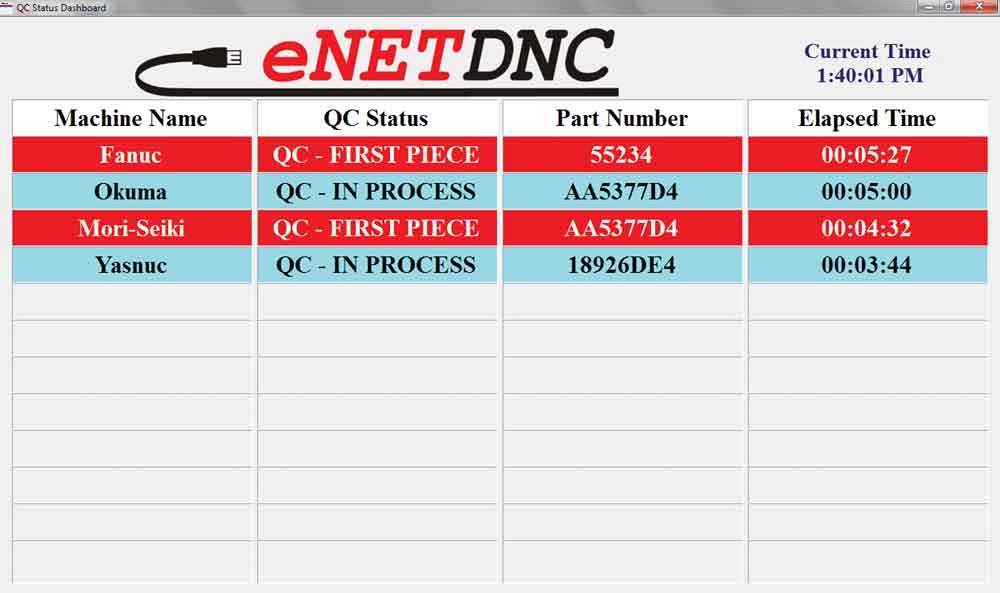

A dashboard displays cycle information for eight machines using Port CNC’s eNETDNC software. Photo courtesy of Port CNC.

Monitoring production isn’t new to any manufacturer. Key performance indicators (KPI) like overall equipment effectiveness (OEE), takt time, and downtime are part of the formulae to schedule jobs, develop quotes, and set benchmarks—regardless of the company size.

Collecting and sharing data from CNC equipment took a leap forward when MTConnect was introduced at IMTS in 2008. The thought behind its development was that if companies could capture process real-time data from controls, devices, and software applications using the Internet protocol, they could proactively avoid downtime and produce more with existing resources. That involves enabling machine tools to collect and communicate information with other machines and the outside world. Dashboards have become a communication tool to share that electronic data in a human-friendly form.

Large companies monitoring hundreds of machines have contributed to the fine-tuning of this technology. But, does this type of data collection and its dashboard displays have a place in small- to midsize shops? Based on three technology suppliers, the answer is yes. It has a place in any company that wants to squeeze out more production without investing in additional equipment, finding room to accommodate more machines, hiring and training more operators, or adding the cost of another draw to the utility bill.

In some aspects, dashboard technology that visually displays real time OEE information may be more valuable to a job shop that deals with high-mix, low-volume parts that dictate frequent setups than a high-production environment where a single part is run on dedicated machines.

Fewer machines are easier to monitor. So what if the process controls in place indicate that the shop is operating efficiently? Ask some questions. Is every operator aware of the OEE of the machines he works with and other equipment that affect production flow? Is current production data available to departments such as engineering and quality control? Does the right person--owner, general manager, shop foreman--know exactly when a piece of equipment needs help to continue making parts? Are the necessary individuals immediately notified of scheduling changes?

Gain From Awareness

The act of monitoring production in real time and making the data immediately visible in an easy-to-decipher format has been reported to increase OEE by 10 to 20 per cent.

A quick, visual reference to what is happening on a shop floor can lead to identification and resolution of difficult-to-diagnose green-light interruptions, especially the sneaky ones that steal a minute here and a few minutes there.

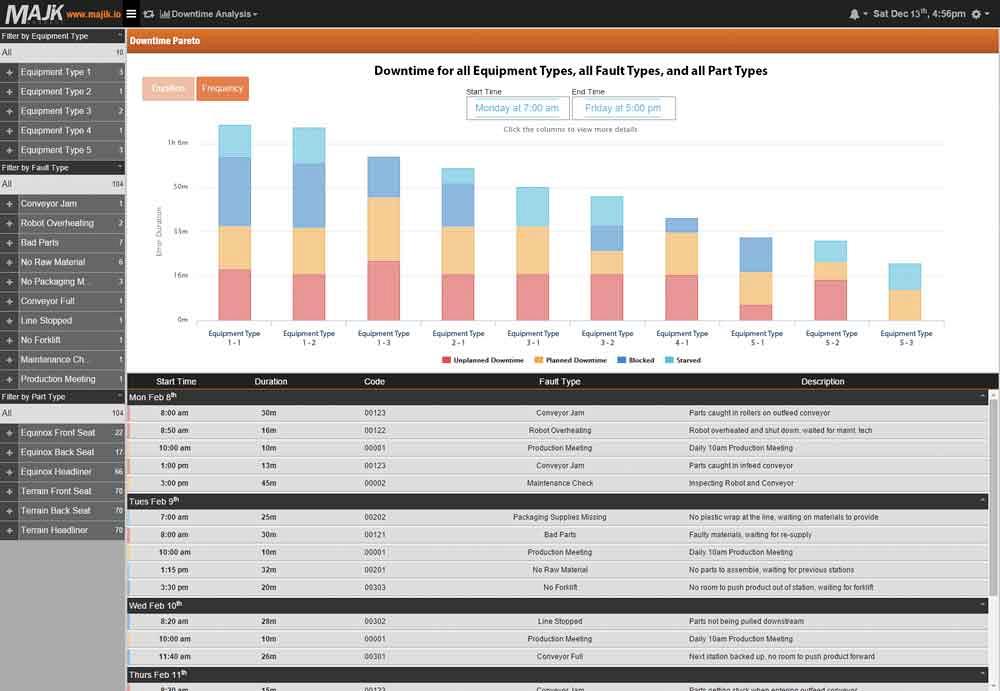

Downtime analysis data provides a complete picture of what equipment paused during production, why, and what actions were taken. Image courtesy of MAJiK Systems Inc.

Ninety-nine out of a hundred times that dashboard analytics highlight unexpected machine downtime, the cause is not within the operator’s control, it’s a problem within the process, said David McPhail, president and CEO of MEMEX Inc. “It’s the way human capital is utilized. The shop may not have enough operators, jobs may not be scheduled properly, tooling may not have been set up, there may not be enough raw material, or there may not be a place ready to put the finished part. All these things affect productivity and profitability.

“Dashboard technology is a tool to help operations understand where the bottlenecks are and take care of the issues. It’s process monitoring. Every minute saved is another dollar.”

Lucas Galindo, eNET sales and marketing manager at Port CNC, said that one custom component job shop was so pleased with the gains from increased visibility on the shop floor after adding dashboard monitors that it implemented a new bonus program for the operators. “The company saw immediate gains from simply capturing and displaying machine uptime and downtime data. Once everyone could see what was going on and where attention was needed, they responded accordingly. The increase in machine uptime was then combined with a bonus program based on spindle uptime. Operators keep track of their own performance and bonus potential in real time.”

Grow Based on Real Data

Jared Evans, product manager at MAJiK Systems, said that dashboard technologies make sense, as well as dollars, for companies in the growth mode. “If you have expanded operations to a point where you can’t see every machine at once or you cannot be at the shop all day because you are making sales calls, dashboard technology can help empower your employees to make decisions that optimize production on their own. If you’ve chosen software that provides off-site capabilities, you can keep up with what’s going on by accessing the dashboard via your smartphone. You can set parameters within the system to alert you to unusual situations, say if a machine is down for a longer-than-usual tool change.”

Evans continued, “As a company adds equipment, it needs to invest in distributed numerical control. It starts to need a more connected infrastructure. It can be a bit of an issue, but services like ours can install adapters for the physical networking of machines from a variety of builders and of various ages as long as the controllers are after about the year 2000.

“An interface can be provided so operators can enter the information that they used to jot on a clipboard at the end of their shift into a tablet or PC as they work. That will allow a company to hit the ground running and start displaying useful data.”

Adapters link a machine to a web server. McPhail explained, “It basically takes a very simple signal, when the machine is under program control or when the light is green, when it is not, and why it is not to the best of the machine’s ability to determine a problem. Those signals allow the calculation of capacity utilization of the equipment, which allows for better scheduling for continuous improvement initiatives based on live data—not data that has been written on a sheet, entered into a spreadsheet, and isn’t available until the next day. It provides real-time data for real-time decisions.”

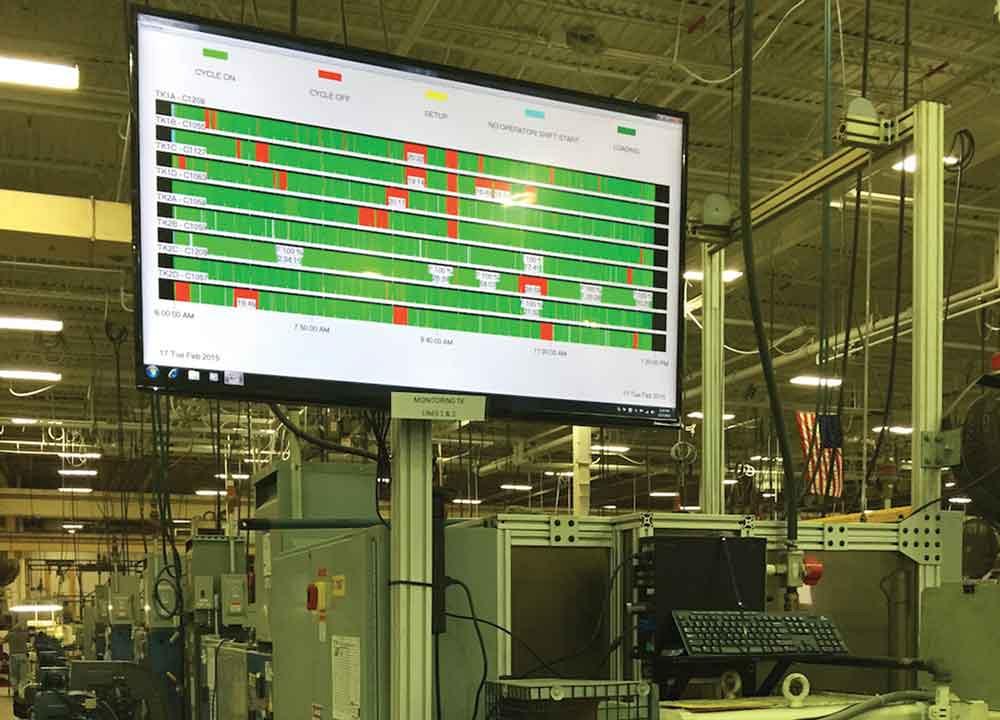

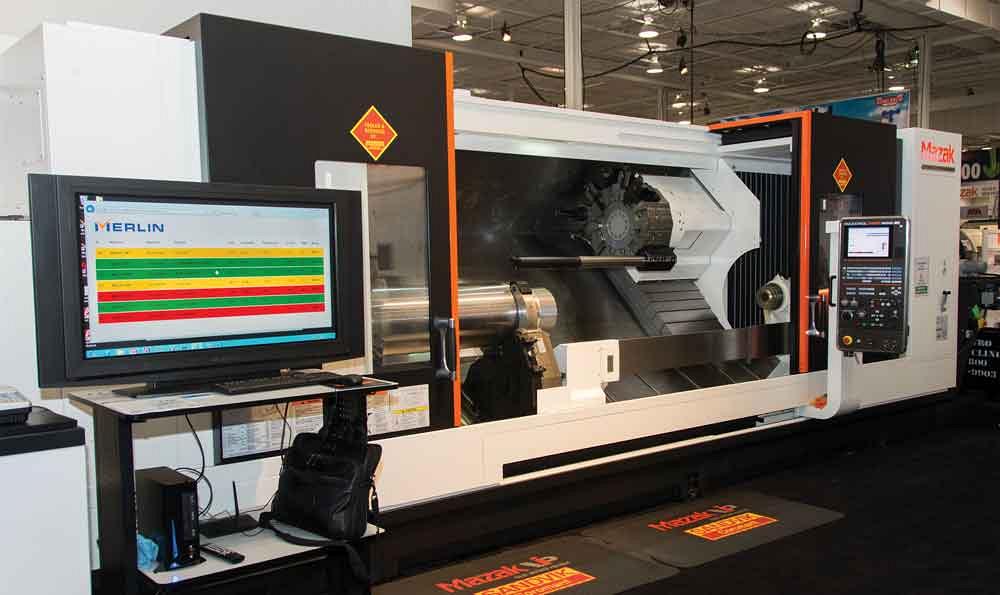

A dashboard displayed on a monitor located at the operator station shows the status of jobs being processed in several machining centers. Photo courtesy of MEMEX Inc.

Address Specific Needs

Galindo said, “Some systems are purely software- and/or cloud-based and they may work with only newer machines that have certain communication protocols or certain types of machine communication ports. Others use a monitoring board tied into a machine’s electrical signal to create an event-driven monitoring system so a machine doesn’t need to be a CNC. Those systems can use the company’s Ethernet network and network security that is already in place to monitor all equipment.

“An operator can scan a bar code to indicate that machine maintenance is needed. He doesn’t have to leave the machine to find a supervisor or track down maintenance personnel. The need is displayed on the dashboard to trigger a response. Or if a setup person is ready for first-piece inspection, he can scan the appropriate code and the message will pop up on the dashboard and stay on the board until an inspector gets to the machine.”

Data shared on a dashboard is highly customizable. What’s important to track and monitor in one shop may not be important in another.

For example, scheduling modules can be part of a company’s package or not. Evans said, “Some companies already have scheduling through another system and that’s fine. But many of the smaller companies view the module as a breath of fresh air because it gives them a way to change schedules and instantly update everyone in the shop. Orders can be viewed as they come in, and everyone understands why changes are made.”

Galindo said to look beyond the shop floor to departments such as finance when considering dashboard technology. “There’s the shop side and the organizational side. The information dashboard technology provides can help employees who are probably not machinists by trade understand what’s happening in the shop. Live dashboards and after-the-fact reports that can be automatically generated help get everybody on the same page. Dashboards show that there will be some machine downtime and that the reasons for it are known and being addressed. Downtime is being turned into uptime.”

Start Small

Evans said, “If a company is just looking for a baseline and wants to try a dashboard software to see if its data is a fit, it can go with something that is just operator input--operators enter information on their current jobs. Perhaps install the technology on two bottleneck machines so everyone can physically see what is happening. Then expand.

Completed, current, and upcoming jobs, and any component weight variance detected by the equipment, are included in the data displayed on a dashboard screen developed by the MAJiK Connect software. Image courtesy of MAJiK Systems Inc.

“One caution: Don’t build software that is too complicated and time-consuming for operators. It can make them feel like it is taking them away from their real job. The information-gathering process should be quick, easy to see once it’s displayed, and relevant.”

Galindo said that starting small gives a company more opportunity to adjust what is measured and how it is displayed. “Start out with a couple of machines and grow into it. That offers more opportunity to work with your customizations before including all machines. The justification and ROI from those first machines will help pay for the rest. It also gives the people on the floor a chance to adjust to the automatic notifications and emails without feeling overwhelmed and discouraged in the first week. Find out where your weaknesses are and use the appropriate software tool to address them.”

Return on investment (ROI) is typically big and fast. McPhail said that on average, companies experienced a 300 per cent total return on capital in a four-month time frame. “That ROI is an average of all the shops we’ve worked with, whether they started with just a few machines or went companywide.

“A lot of companies want to get a handle on their production. It’s no different if they have five machines or 500. The challenge is the same,” McPhail continued. “If you have the ability to visually see your processes--to know when your equipment is running, when it’s not, and why it’s not--then you have the basis to improve utilization.”

Referring to acceptance by operators, Evans said, “Our workforce in North America is well-educated and trained. CNC operators are smart individuals who want to do their jobs well. When this type of software is introduced they know it will help address any problems they are having. But, this software will not magically make equipment run faster or have less downtime. It’s all about the people using it.”

Associate Editor Sue Roberts can be reached at sroberts@canadianmetalworking.com.

MAJiK Systems Inc., 519-575-5538, www.majik.io

MEMEX Inc., 905-635-1540, www.memex.ca

Port CNC Inc., 414-817-7070, www.portcnc.com

About the Author

Sue Roberts

2135 Point Blvd

Elgin, IL 60123

815-227-8241

Sue Roberts, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. A metalworking industry veteran, she has contributed to marketing communications efforts and written B2B articles for the metal forming and fabricating, agriculture, food, financial, and regional tourism industries.

Roberts is a Northern Illinois University journalism graduate.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI