- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

CNC Solutions: Data Driven Manufacturing

Manufacturers should be prepared to store large volumes of data.

- By James Brown

- January 7, 2016

Thanks to the advent of many types of production software and hardware technology, along with the accessibility of telecommunications technology and the Internet, getting the most out of a shop-floor environment is just a mouse-click away.

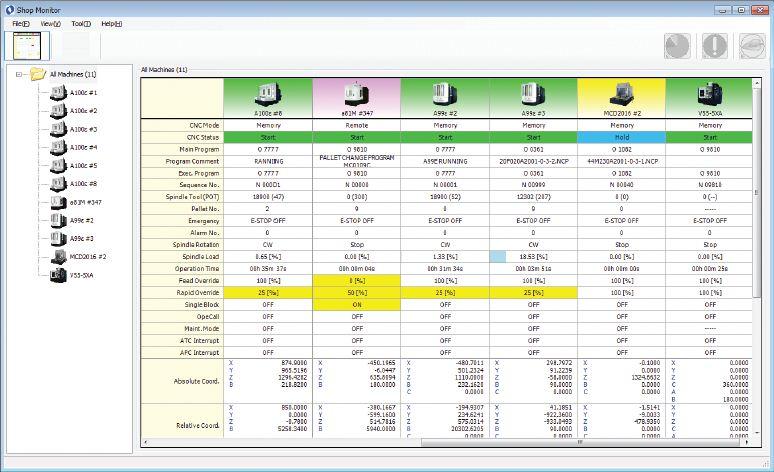

When multiple machines are connected to a single network to a centralized computer, data-monitoring software can enable a manufacturer to retrieve, store and analyze high volumes of actionable machine data in real time, eliminating the need for manual data collection.

This data can provide detail about part counts, cycle time and tool life.

In addition, production and status data can be collected directly from the machines. Such information enables shop personnel to react quickly when bottlenecks occur, ultimately preventing downtime and yielding more parts per machine.

Data monitoring is employed in many manufacturing environments—from very low-mix automated environments to high-mix automation or stand-alone machines—and should no longer be considered exclusive to large companies.

Data can potentially be accessed from anywhere in the world to improve productivity and help a company reap the most from its machine investment. Those shops wanting to implement a monitoring solution must first decide what data is most important to record and retrieve. Some of this information includes machine utilization data to help calculate ROI, and machine downtime to eliminate load and unload bottlenecks. Data monitoring software has a wide range of standard and advanced features:

- Standard actionable data that can be tracked

- Multiple machine status

- Machine utilization

- Power monitor

- Camera monitoring

- E-mail notifications

Advanced monitoring features offered by select vendors:

- Probe data analysis

- Tool management

- Work scheduling

- Spindle monitoring

The open-architecture machine communications protocol called MTConnect gives manufacturers the ability to connect their software packages to all types of machines.

This software is becoming more widely available in newer machines, but it can be retrofitted into older machining systems

as well.

Implementing the data-monitoring software requires several preparations including Ethernet and wiring, training, backup, introducing it to the staff, and determining how to handle all of the stored data.

When choosing the right monitoring solution, it is critical to have the support of a provider that offers tight integration between the software and the machines. The ideal software provider should be able to speak knowledgeably to both machinists and IT personnel, ensuring that machine settings and processes are optimized and networks are compatible with company security protocols.

Training should also be offered to help users learn how to analyze the data and gather insights.

Once the data-monitoring software is set up and is collecting information, the data can then be reviewed to determine if there are any bottlenecks or opportunities for improvement in the manufacturing process.

The manufacturer can then work through each gridlock, perfecting processes to achieve optimum workflow efficiency.

With improved efficiency comes better cost per unit, which goes right to the company’s bottom line, and enables it to expand the operation.

Manufacturers should be prepared to store large volumes of data.

With access to plenty of historical machine process data, companies can be more effective at tracking progress and identifying opportunities for process improvement.

By using production monitoring software manufacturers can have greater confidence in their operation than ever before.

James Brown, Controls Software Development Manager, Makino Inc.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI