Technical Advisor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Quantum Leaps and Steady Progress

The relentless ascent of the (not so humble) carbide insert is characterized by revolution and evolution

- By Andrei Petrilin and Marcel Elkouby

- June 22, 2016

Cemented carbide is a hard material that is used extensively in cutting tools that are intended for machining. Within an industrial context, the terms carbide or tungsten carbide usually refer to this cemented composite.

Carbide cutters deliver many advantages. In the majority of cases, they provide a better surface finish on the machined part and allow faster machining when compared high-speed steel (HSS) cutters.

In addition, carbide tools are able to withstand higher temperatures at the cutter/workpiece interface than standard HSS tools, which is the principal reason for their faster machining capability. Carbide usually provides superior performance for the cutting of tough materials such as high-alloyed steel and stainless steel, as well as in situations where other cutting tools would wear away faster, such as when performing high-quantity, extended production runs.

Replaceable Carbide Segments

Industry’s use of cemented carbide for cutting metals began in the 1930s. Since that time carbide has become by far the most popular material for the production of cutting tools. While some tools that are relatively small sizes are wholly produced from carbide, others contain carbide in the cutting area only. Originally, the cutting area consisted of a carbide tip that was brazed or soldered to a tool body. However, in the 1940s cutting tool manufacturers began to produce cutting tools with replaceable carbide segments that were mechanically mounted onto the tool body.

This clever innovation and the use of mechanical clamping, which provides much greater strength compared with the previously brazed connections, are now recognized as memorable milestones not only in the area of tool manufacturing, but also in advancing the efficiency of all metalworking industries.

This major development led to improvements in productivity within the area of machining operations. It was immediately possible to increase the load on the tool and to intensify operational metal removal rates. In addition to this cost-effective method of ensuring the simple and economical replacement of the cutting element when it became worn or broke, it allowed the separate manufacture of the cutting segment and the tool body.

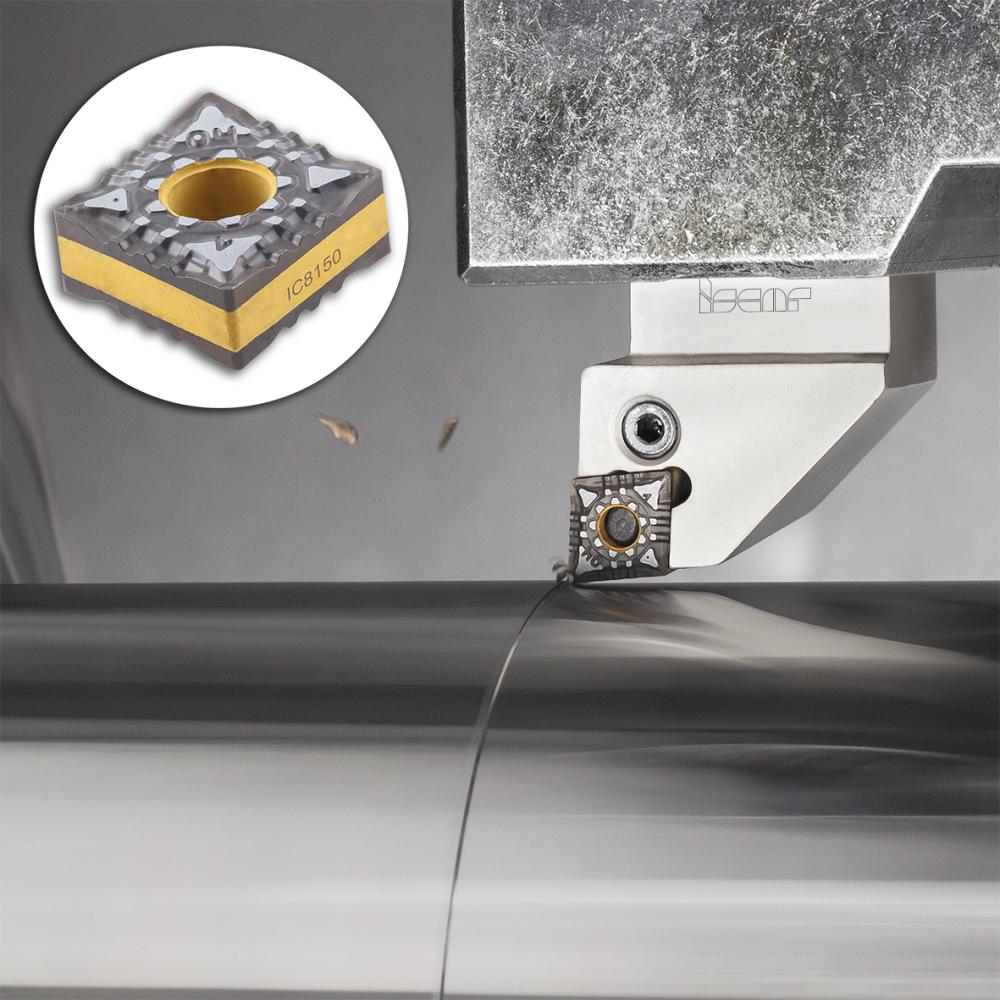

Depending on the shape of the inserts used, they could be quickly indexed, ensuring the rapid changeout of a worn cutting corner by several methods, such as rotating the insert on its axis or by flipping it upside down. Initially the new cutting segments were known by several names, such as throwaway tips, interchangeable inserts, and replaceable inserts; today the more widespread, generic term is indexable inserts.

The technology used in the manufacture of indexable inserts is based on powder metallurgy, which comprises several manufacturing processes:

- Preparing carbide powder (mixing).

- Pressing the powder (compacting).

- Sintering compact.

- Postsintering processing.

- Coating.

In principle these stages have remained unchanged over many decades. Although, at the same time, progress in science and technology has significantly affected the manufacturing process of inserts.

In the past inserts were produced by on manual machines. Hence, the application of various complex powder metallurgical processes was very difficult or even impossible to perform. The introduction of more progressive industrial equipment, featuring advanced automation and computer control, made the technological processes more stable, controllable, and reliable. Consequently, the mechanical properties of manufactured inserts became more uniform, predictable, and repeatable.

These factors allowed improvements in terms of the accuracy of sintered inserts by reducing production tolerances.

Now a typical insert production press is a highly engineered device that is computer-controlled. A movable punch can be made from several subpunches, each operated separately. Some press designs encompass multiaxial pressing options. The progress in press technology enables the production of complex shaped inserts that are characterized by variable corner heights (see Figure 1).

This capability enables the realization of optimal cutting geometry, which guarantees not only smooth and stable machining, but also a more accurate machined surface (see Figure 2).

The advantages modern CAD/CAM systems provide make it possible to improve the design and the shaping parts of pressing die sets. The ability to simulate the pressing processes for new sintered products when they are at the beginning of their design stages allows further design amendments and enhancements to be made.

Advanced new techniques for sintering insert masters improve process quality. Gradient sintering of multicarbide substrate ensures a thin upper layer that has high cobalt content. This gradient layer produces an excellent barrier against the development of cracks and guarantees increased resistance to brittleness and fracturing. Substrates of this type are commonly used in tools intended for turning operations.

Coatings

Until the 1980s carbide grades were uncoated. In order to make grades more universal and suitable for machining various engineering materials, tool manufacturers invented grades that contained var

ious additives.

The adoption of coating technologies changed the world of machining, and now the vast majority of carbide grades are coated. The addition of this new technology permitted the grades to focus on cutting specific material groups. The substrates contained fewer additives so their structures became more uniform and stable, which further improved control during production.

The introduction of coated carbides and ongoing developments in this area have enabled significant increases in cutting speed.

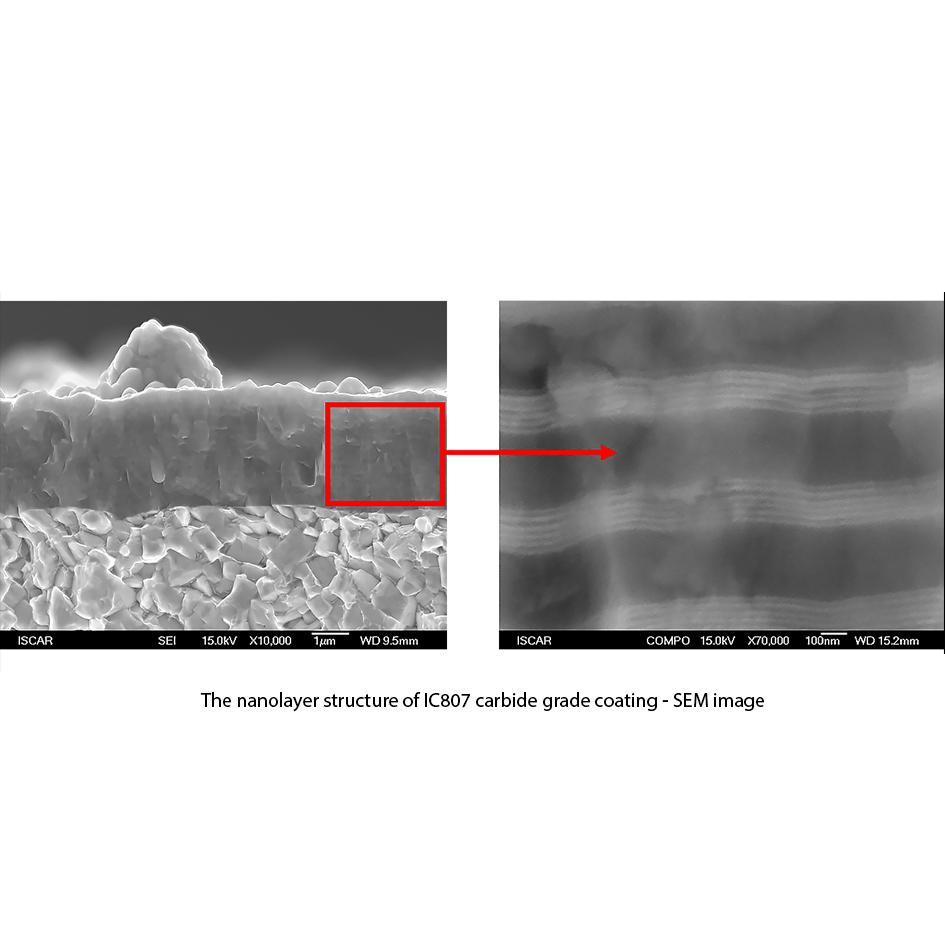

Coating technology continues to develop in two principal directions: chemical vapor deposition (CVD) and physical vapor deposition (PVD). The main result of progress within the area of CVD was the introduction of alumina ceramic coatings. They allow machining at elevated speeds because of its excellent temperature isolation properties, high hardness, and chemical stability at high temperatures.

PVD coatings brought a new class of wear-resistant nanolayered coatings. Such coatings (Figure 3) are a combination of layers having a thickness of up to 50 nm and are strong compared to conventional methods.

Modern technology allows both CVD and PVD to be combined for insert coatings as a means of controlling coating properties.

Another major advancement in insert technology relates to postcoating treatments. Postcoating technology delivers improved strength and wear resistance to carbide grades, enabling higher productivity.

Andrei Petrilin is technical manager of indexable milling and Marcel Elkouby is material science engineer manager, Iscar Tools, 905-829-9000, www.iscar.ca.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Authors

Andrei Petrilin

2100 Bristol Circle

Oakville, L6H 5R3 Canada

905-829-9000

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI