- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Business Profile: Mahler Industries

This Coquitlam, BC-based company is committed to quality.

- By Doug Picklyk

- August 31, 2015

- Article

- Metalworking

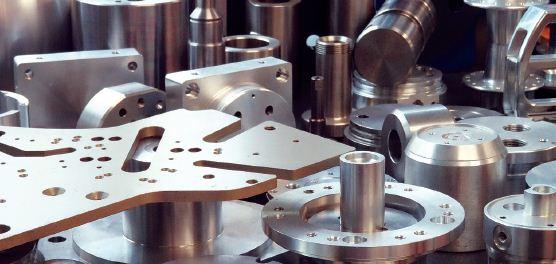

In a modern-looking industrial unit with plenty of windows facing the street, Mahler Industries is a CNC machine shop with an equally modern approach to business with a focus on efficiency and a commitment to quality and service that keeps the Coquitlam, B.C. company on a steady growth path.

The history of the business dates back to 1983 when it was started by the Mahlers. Originally called Bold Brass Designs, it specialized in ornamental brass work. Gradually the company evolved into a more diversified machine shop, changing its name to BBD Machining.

In 1997 the business moved to its current 20,000 sq. ft. site in Coquitlam changing its name to Mahler Industries in the transition.

It was two years prior to that move that Pedro Fernandes joined the business. A Burnaby native, after working in a machine shop during high school, Fernandes went to the British Columbia Institute of Technology (BCIT), and at the age of 20 started working as a machinist in Mahler’s manual department. At that time there were about 10 employees and six CNC machines tools on the shop floor.

After almost 14 years with the company, in February 2009 Fernandes and his wife Carlynn together acquired the business. “I never really had any intention of starting my own business, but the opportunity came up to buy this business, and I talked my wife into it,” says Fernandes, now 41.

Early 2009 was a challenging time for every industry following the 2008 U.S. banking collapse and the economic recession that followed. “The company had experienced steady growth from when I started [in 1995] through to 2008,” recalls Fernandes. But he had confidence the business was strong enough to carry on, and by late 2010 and 2011 business started picking up again and it’s continued for the last three years.

Today Mahler employs some 25 people and prides itself on its reputation for providing solutions for customers with an emphasis on service and high quality production.

Like other shops in the area its client base is diverse, servicing various industries including aerospace, marine, medical, forestry, mining, pulp and paper, among others. “We try to cover most sectors. I think you have to here in B.C.,” notes Phil Archer, sales manager with Mahler.

Standing in front of a Mazak Integrex i-300 five-axis lathe with live tooling, Phil Archer, sales manager (left), and Pedro Fernandes, president, Mahler Industries.

Archer notes that forestry used to be a main industry, and it’s starting to pick up more steam. About 80 per cent of their client base is local with the other 20 per cent outside of B.C. and international.

“There was a period of a couple decades where the larger volume work going was all going offshore, and that’s starting to come back,” says Archer.

“Customers don’t always want to buy 10 times what they need,” adds Fernandes. “They’re willing to pay a little bit more in order to buy only what they need and not having to wait six months for it.”

There are not too many machine shops of Mahler’s size in the immediate area, but the market is as competitive as anywhere else. “You have to be better than your competition to be able to excel at what you do,” says Archer, and when it come to quality and delivery Mahler maintains a solid reputation. “We can do both the production runs and we can do prototyping—that’s our strength,” says Fernandes.

Quality control is a foundation of the business, employing two full-time quality personnel in its dedicated quality control room outfitted with a Mitutoyo CMM among other quality instrumentation. Mahler also offers a rapid prototyping service to clients using a 3D printer.

The company is also ISO 9001 certified to ensure overall operational quality assurance, and it also has controlled goods certification to deal with military/defence business.

When Fernandes bought the company in 2009 there were 13 CNC machine tools on the shop floor. They now they have 17 (14 Mazaks and three Haas). “When I see our customers have a need, we buy new machines to stay ahead of the game,” he says. They’ve added five new machines for extra capacity.

Among the new machines is a multi-tasking Mazak Integrex i-300 five-axis with live tooling, allowing for multiple operations with one set up, a Haas VF 9 vertical machining center increasing the size of parts they can work on, two additional Mazak turning centers (both with live tooling) and a Haas DT-1 drill/tap center.

Aside from machine tool efficiency, the company also effectively manages its cutting tool consumption with an inventory management solution, using the Cribmaster ProStock vending machine system on the shop floor.

Installed a few years ago, it’s managed by Integrated Solutions, a division of Western Canadian distributor Thomas Skinner and Son. Fernandes notes how the system provides savings in administration time and cost. “It’s cut down on the paper work, and we don’t have to order multiple inserts at once,” he says. “If the guys need one tool, they just take one. It saves us money. You don’t have to write up a P.O. for a box of inserts when you only need one or two.”

On the shop floor Mahler employs mostly journeymen who can program, set up and run the jobs, providing the ability to control the quality of work from start to finish. The entire shop floor is temperature controlled, which speaks to the company’s quality commitment, but it also provides a comfortable work atmosphere for the employees. Of the 25 staff, about one-third have been with the company for 10 or more years.

Mahler is currently running day and afternoon shifts, with the ability to ramp up to 24 hours if required. Fernandes himself can be found on the shop floor every day from 7:30 am to 6 pm. “I love my job,” he says. “I loved being a machinist when that’s all I did, and I still like being a machinist. I like making things and being challenged everyday. I’ve always liked that.”

And he’s comfortable with the size of the facility today. “We don’t need to move to a larger facility to be able to increase our capacity. With the work we currently have we have the right amount of staff, and if work increases we have the ability to ramp up and hire new staff and potentially bring back a night shift,” he says.

The focus for Mahler is to continue to grow and improve the operations going forward. “You have to keep investing in the business,” he says. “I have a long time to go before I retire, so I want to keep building something.”

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI