Associate Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Business Profile: The Machining Center

Short run specialists in Belleville, ON.

- By Lindsay Luminoso

- May 21, 2015

- Article

- Metalworking

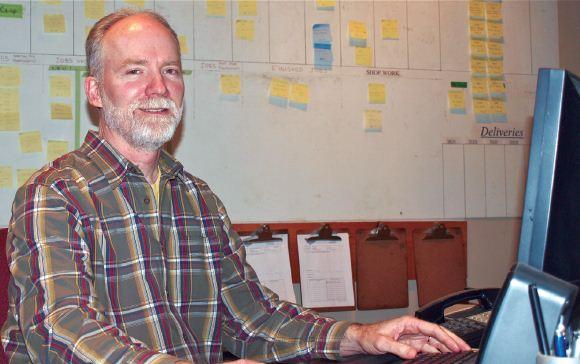

Located outside the hustle of the city and surrounded by acreages and farmland, there are actually horses grazing in the field behind The Machining Center, but there’s no horseplay going on inside. It’s all business for this machining and fabricating shop that has been experiencing what owner Dick Wolters calls “consistent and controlled growth” since it began operating in 1988.

The full service company has built its success through sound investments in its infrastructure (both its people and its technology) and by developing a reputation as a reliable partner for its diverse range of clients.

Wolters’ career began as an apprentice back in 1979 in Trenton, Ontario, located about 180 km east of Toronto along highway 401. A few years after completing his apprenticeship and working at a local tool shop, he and a colleague started up their own business in a Trenton industrial park. That partnership lasted three years before the two decided to go their separate ways, and Wolters launched The Machining Center down the road in an 800 sq. ft. unit with one CNC mill and some manual machines.

Taking in a variety of work, over the first few years his business began to grow, adding people and space. In 1996 Wolters strategically re-located midway between Trenton and the city of Belleville, moving into a 10,000 sq. ft. building that had previously been an indoor horse riding stable. He initially setup the machine shop into 2,700 sq. ft. of the building and rented out the rest. With continuous expansion over the last two decades The Machining Center now occupies the entire building and 4,000 additional sq. ft. added in 2011. The company currently employs 16 people, 10 on the shop floor and six in the office.

Specializing in custom work, the company services customers from a wide variety of industries on projects from early concept through design to finished parts.

Services on the shop floor include CNC milling and turning, grinding, hardening, CMM measurement, welding, bending, sawing, punching and cutting.

“We’ve become a resource for local industry,” says Wolters, pointing out that some 98 per cent of the company’s work comes from within a 30-mile radius.

Industries served include aerospace, nuclear, food processing, plastic extrusion, wire and cable, and agriculture, among others.

“What we’ve tried to do is branch out our customer base into many different sectors,” says Paul Vreugdenhil, operations manager, explaining that as some industries slow down others will pick up, keeping their shop busy all the time. Vreugdenhil adds that exposure to that variety introduces a wide range of materials into the shop and many different processes that his team needs to be aware of, requiring everyone at the shop remain sharp and flexible.

Vreugdenhil actually apprenticed at Wolters’ first shop in Trenton in the mid ‘80s, and then over a decade later, while he was working as machine shop coordinator at a major converting/manufacturing plant in the area, Wolters stopped him on the street and offered him a job on the spot. Since joining The Machining Center in 1998, Vreugdenhil’s played a strong role in managing and developing the shop’s technology platform.

One of the most significant moves was embracing Solidworks 3D CAD design software in 2004. “We were the first ones in this area to be working with Solidworks and also GibbsCam (for programming the CNC machines),” says Vreugdenhil. Working with those applications for over 10 years now has given the shop valuable experience, and it’s also given them a lot of digital files.

The shop is very process oriented, becoming ISO certified in 2007. “We do a lot of data management,” says Vreugdenhil, noting how that ability, tied in part to the Solidworks application, has become a valuable customer service opportunity. “We regularly get requests to call up past jobs,” he says, and because of their information management system they’re able to go back to work done as far back as 1995 and find data files for a part.

“I actually received an email the other day from a customer looking for engineer-stamped drawings,” says Wolters. “Within 20 minutes I put them in an email back to her, and she was so happy. In a busy world where faces are changing all the time, we’re the good old boys still taking care of things, and customers appreciate that.”

Vreugdenhil agrees: “Our customers have that sense of security and comfort knowing that we’re going to handle their work with care—not only the machining or fabrication of the parts, but also all of their information. That’s a huge key to our success.”

And while The Machining Center has built a reputation for reliability in machining and fabricating great parts, according to Wolters, “process development is where we shine.”

“Our customers recognize us as production partners,” adds Vreugdenhil. “We’re willing to invest the time and money to work with companies to help define and refine their processes or improve their productivity. They see and respect that effort.”

Their experience in product development actually contributed to a recent award-winning innovation conceived by Wolters’ son and daughter-in-law. Their product, a portable housing solution for farm animals called “The Calf Canopy”, received a Farm Innovation of the Year award from Farm and Food Care Canada. The product’s development demonstrated the shop’s ability to move from concept, to prototype and sellable product over the course of five months.

While designing and producing their own product was new for the company, they were very familiar with the process, having helped many other businesses down that path.

But Vreugdenhil is quick to point out that moving into their own product development will not become a key business for The Machining Center. The company’s focus remains on helping other clients improve their processes and develop better products.

Apart from design and process, the sweet spot for the shop is taking on low-run custom jobs—particularly challenging parts. “We specialize in the weird and the wonderful,” laughs Wolters.

“The industry is very competitive on parts that many different shops can do,” explains Vreugdenhil. “Where we win is where customers come in with very particular parts that require meticulous attention or low-run projects. Because our set up time can be very short we regularly win bids on low-run 10- or 20-piece jobs.”

Key to the shop’s quick set ups are the programming skills and capabilities of their operators. On the machining side of the business they have four CNC mills and three CNC lathes. The most recent addition to their line-up arrived late last year with the installation of a new multi-tasking Nakamura-Tome precision lathe, purchased from Elliott Matsuura.

“Our new machine offers us the flexibility to be able to do operations on one machine that we were doing on multiple machines before,” says Vreugdenhil.

“There would be times where all of our lathes were busy and our mill work was slow, or more often the mills were crazy busy and the lathe work was up in the air,” he says. Looking for a solution, he noticed that most turning jobs also required some milling operations after, so now with the new multi-tasking machine they can do a lot of the turning and milling operations with one set up.

Flexibility is one reason they bought the lathe, and the other main reason was to bring in new technology to challenge their operators.

Like other machines they’ve purchased, Wolters and Vreugdenhil were very deliberate in their research. Once they had narrowed down the field to three options, they brought their operators along to provide input on the final decision.

Vreugdenhil notes that some machine tool sales people were shocked by that move. “We’re very invested in our employees,” he says, adding that the more ownership their operators have in decisions the more it encourages them to be engaged in the equipment and the future of the company.

Wolters notes that early on in the process, before they had even selected the final machine, they sent their operators out for a two-day stint with GibbsCam for multi-tasking machine training. “We wanted to let them get a feel for what it was going to take, and how it was going to change their lives.”

The new Nakamura-Tome turning center was The Machining Center’s first time working with Elliott Matsuura. “They’ve been excellent,” says Wolters, adding that the people at Elliott have consistently been able to anticipate their needs.

“We experienced a few hiccups at the very beginning, and the way Elliott dealt with that was phenomenal,” adds Vreugdenhil. “At one point our operator emailed their service guy a couple times during the week, and the guy called up and was here the next day just to help us out.”

CAM Solutions Inc., reseller of GibbsCam, was also a huge help. They offered flexible training times and helped our team onsite, to learn the nuances of the software to write programs for our new machine.

While shops of their size may be more likely to buy this type of equipment through an auction, the support and service they’ve received have gone a long way in justifying purchasing brand new.

And Wolters is comforted in knowing that the new multi-tasking turning machine can handle about 60 per cent of the type of jobs coming through their shop, freeing up other machines on the floor for more work.

When Vreugdenhil looks at the company’s entire operation today he’s amazed at their increased productivity, a feat he attributes to the skills and capabilities of his team along with the quicker programming time and the speed of the equipment. “It surprises me because we‘re doing more work now with less people than we’ve ever done before,” he says.

Looking forward, Wolters says the company is currently building its next five-year plan. As far as what new technology will be arriving on the shop floor next, both Wolters and Vreugdenhil approach those decisions cautiously. There’s no need to rush, they insist. They’re happy, proactively evaluating options and breathing the fresh air of their wide-open rural surroundings.

Business is good.

About the Author

Lindsay Luminoso

1154 Warden Avenue

Toronto, M1R 0A1 Canada

Lindsay Luminoso, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI