- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Perfect Pairing

Together TMW and Velocity Machining & Welding keep Halifax manufacturers in precision, custom components

- By Sue Roberts

- May 1, 2017

- Article

- Made In Canada

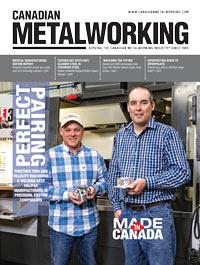

Craig Langille (left), vice president, and Sean MacPhee, president, of Techtronics Machine Works and Velocity Machining & Welding in Nova Scotia hold work samples in front of one of TMW’s Haas 5-axis machining centres.

Techtronics Machine Works (TMW) in Musquodoboit Harbour and Velocity Machining & Welding in Dartmouth, N.S., have Sean MacPhee and Craig Langille in common. The two cousins, both machinists by trade, embraced manufacturing at the beginning of their careers and became business partners when they began Velocity in 1999. Now in their mid-40s and co-owners of two shops, MacPhee serves as president and runs TMW, and Langille fills the vice president role and manages Velocity.

“Providing precision, custom machine components and excellent customer service is a trait Craig and I shared long before we bought TMW in May 2015,” said MacPhee. “The former owner, Ron Marks, had thoughts and an approach to business that were pretty close to ours, and that was important to him. Our business philosophy had to be a fit before he would make the sale.”

Langille added, “He was very keen on the fact that we are two young guys who think like him and aren’t going to retire anytime soon. He saw how we maintain great working relationships with customers, the way we treat our guys and how they treat us, and that we keep up with technology and keep our equipment current. It all made sense to him.”

When MacPhee and Langille investigated TMW before the 2015 purchase, they found that the growth patterns of the two companies closely paralleled each other. Both shops were adept at producing prototypes, manufacturing components for product lines, machining directly from engineering drawings, and problem-solving.

Similar Growth Patterns

In 2012 Velocity expanded and moved into an 11,000-sq.-ft. location. TMW invested $2 million in 2009, growing the company to today’s 9,000 sq. ft. to accommodate a second CMM and new Haas equipment.

Velocity’s location, machining and fabricating capabilities--including welding, shearing, bending, additive manufacturing, laser and waterjet cutting, and on-site and off-site repair and rebuild services—helped the company build the larger of the two customer bases. The TMW purchase was, in part, to acquire resources to accommodate work that didn’t fit in the Velocity schedule.

Many TMW customers required Controlled Goods Program registration and ISO 9001:2008 certifications to produce complex parts, manufactured to exacting specifications, and proof of meeting those expectations. Those certifications were in place at TMW.

“Some TMW customers are multinational and export what we make for them all over the globe. Components made in our shop are at the bottom of the sea, the top of the sea, you name it,” said MacPhee. “Our customers need parts for equipment that does oceanographic research and offshore gas exploration. Components made in our shop are in equipment for scientific instrumentation, defense equipment, and many types of industrial machinery. We like to be diversified.”

TMW’s full shop floor has nearly a dozen Haas CNC lathes and mills. The work envelope on the largest of the two 5-axis mills is 50 in. by 26 in. by 25 in. Equipment in the manual workcells includes five mills and ten lathes. Two CMMs and a surface roughness tester, all from Mitutoyo, are housed in the dedicated quality control room.

Stainless steel, INCONEL® alloy, titanium, aluminum, copper, brass, and plastics flow both shops and both stock some materials. Velocity stocks a greater amount so it can respond immediately to emergency repair jobs, and TMW keeps a supply of exotic materials that may have a long lead time so there are no delays should a rush job come in.

Talented Tradespeople

MacPhee and Langille proudly claim to have the best tradespeople in the industry. Twenty-three employees are credited with being TMW’s major strength. They keep components flowing through the shop during two shifts. Twenty-six employees do the same for two shifts at Velocity.

“We don’t have an engineering department, but we have very talented people who work directly with our customers’ engineers. We design for manufacturing based on knowing the shop capabilities. Our employees understand how to produce a component so it is both functionally effective and cost-effective for our customers.”

Langille and MacPhee both have concerns regarding finding the kind of tradespeople they want as the companies grow.

“We talk to the local community college and government groups about the need to fund programs to attract and train tradespeople beyond welders. We try to point out that if job shops like ours didn’t do what we do, all major industries in our province would have to relocate to find the machining services that they require to keep their operations viable. If they don’t have manufacturers to help get their products to market, their prototypes built, or repairs made, it all stops. The metalworking industry is the foundation of everything that happens in the industrial sector,” MacPhee said.

They added that the training has to produce tradespeople with deductive as well as technical skills, and who feel a sense of ownership and pride in performing their jobs.

Referring to the employees at both locations, Langille said, “An operator has a $140,000 machine turning a $10,000 part and he can’t get distracted. If he turns his back or hits the wrong button, it can not only scrap the part that has a week’s worth of work in it, but the customer won’t get the part by the due date.

“We have high expectations for all our employees. If an employee doesn’t take pride in what he does, we don’t want to deal with him. Every person has to use his brain, not just push a button or point a welding gun and pull the trigger.” Langille continued, “Because of the custom work at both locations, the employees have to be able to deal with customers’ needs and make quick decisions. And when customers come into the shop, I want the employees to be able to talk with them and understand the projects and the steps needed to get the jobs done.”

Both shops are willing to train the right people. “One of our best hires was a guy who started with no skills but was interested enough in the trades to knock on the door. He volunteered to work for free to learn and after two weeks we hired him,” said MacPhee. “He’s apprenticing with us now.”

Beyond Components

One thing that was always at a shortage before TMW joined with Velocity was product development time for the company’s own product ideas.

“We do a lot of product development for various customers,” MacPhee said, “but before the TMW acquisition, it inevitably turned out that we didn’t have enough time to work on products we wanted to develop. The acquisition has given us more time and we have a product ready to go.”

That product is a belt grinder that was three years in the making because it had to be sandwiched in between customer jobs. The design was prompted by personal hobbies—MacPhee relaxes by producing custom-built knives; Langille enjoys stock car racing and performs the chassis and body work that comes along with the sport.

Custom stainless steel parts, produced to exacting specifications, go into equipment used in oceanographic research.

“Our VBG272 belt grinder was designed by machinists and fabricators for machinists and fabricators,” said MacPhee. “The goal was to provide a full-featured, user-friendly, affordable grinder. Its starting price is $1,380.”

Features on the 2-in. by 72-in. belt grinder include guards that do not interfere with changing the belts on all non-contact wheels; a swing-away, height-adjustable, 8-in. by 4-in. worktable that can be used in the horizontal or vertical position; and different drive wheel sizes to change speed. It will be sold with or without 1-, 1.5-, or 2-horsepower TEFC (totally enclosed, fan-cooled) motors. An optional tube and pipe coping attachment will be available soon.

Experience Benefits Customers

“We are both tradespeople and we can go down on the floor and do the work. We’ve been fortunate to see and learn by doing. We’ve worked down in the belly of ships and on top of cranes. We’ve gotten a bucket of parts that had to be put back together without knowing how they came apart. Those kinds of life experiences provide benefits for our customers,” said Langille.

“Having the two companies has worked out well. At Velocity we can take something from paper and machine it, weld it, remachine it. If it has extremely tight-tolerance bores, crazy angles, or requires five axes to produce, we can send it to TMW. Joining the two companies has made both of them stronger players in the industry. They work together, and each company can offer the whole package. What we can’t do at one we can do at the other,” Langille continued.

MacPhee and Langille look forward to more growth in the Halifax area. They like to maintain a position where they can capitalize on opportunities.

“Our business started small. We had cash in our pockets and purchased some used equipment,” said MacPhee. “Now it’s progressed to a larger scale, but we still have the same philosophy. We plan to grow, whether by expanding again at TMW or acquiring another company. It will be dictated by the work that is available.

“The industry is competitive, but a lot of companies are competitors one day and customers the next. Our customers benefit from our bringing these two companies together. It’s really a case of the sum being greater than the parts.”

Associate Editor Sue Roberts can be reached at sroberts@canadianmetalworking.com.

Photos by Marvin Moore Photography.

Techtronics Machine Works Ltd., 902-889-2418, www.tmwltd.ca

Velocity Machining & Welding, 902-434-4428, www.velocitymachining.ca

About the Author

Sue Roberts

2135 Point Blvd

Elgin, IL 60123

815-227-8241

Sue Roberts, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. A metalworking industry veteran, she has contributed to marketing communications efforts and written B2B articles for the metal forming and fabricating, agriculture, food, financial, and regional tourism industries.

Roberts is a Northern Illinois University journalism graduate.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

ZEISS Quality Innovation Days 2024

- April 15 - 19, 2024

Tube 2024

- April 15 - 19, 2024

- Düsseldorf, Germany

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada