- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Automotive Manufacturing Report

Do high-tech vehicles + booming Mexican production = opportunity?

- By Nate Hendley

- July 20, 2015

- Article

- Metalworking

Automotive production is holding steady in Canada, rising in America and booming in Mexico, all of which spells opportunity for Canadian suppliers, say experts.

The rise of high-tech “connected”, autonomous, electric/hybrid vehicles is also potentially advantageous for well-positioned suppliers. And other positive tidings include continued government support for automotive innovation and a new federal fund for small-to-medium size suppliers.

A total of 2.393 million vehicles were produced in Canada in 2014, according to the Paris-based International Organization of Motor Vehicle Manufacturers (known as the “Organisation Internationale des Constructeurs d’Automobiles” or OICA). This is a 0.6 per cent increase from the year before. In 2014, U.S. vehicle production stood at 11.660 million (up 5.4 per cent) while vehicle production in Mexico was 3.365 million (up a huge 10.2 per cent).

The auto industry has recovered well from the recession which saw Canadian production dip as low as 1.2 million vehicles a year and total North American production drop to 8.8 million.

“I think the main thing is really to highlight just how strong North America as a whole is at the moment…we’re looking at production and sales across the region. So we’re looking at Canada, the U.S. and Mexico as three countries combined…our view is the sales and production across the region are going to continue to expand,” states Carlos Gomes, senior economist and auto industry specialist at Scotiabank.

Gomes authored a pair of highly optimistic Global Auto Reports for the bank. “The strength of the Mexican auto market will help lift North American sales and production to record highs this year, surpassing the peak that has been in place since the turn of the millennium,” reads the Scotiabank Global Auto Report published May 7, 2015.

If the overall picture for North America is rosy, the specific situation in Canada is also promising.

“Record auto sales and production across North America are reviving the Canadian auto industry. While the sector has undergone significant consolidation over the past 15 years and is much smaller than at the turn of the millennium, most indicators suggest that the Canadian auto industry is now performing at least in line with its two North American partners. In fact, we highlight that the auto sector is leading the manufacturing revival across the Canadian industrial heartland, is gaining market share globally and momentum has accelerated in the opening months of 2015,” states another Scotiabank Global Auto Report published April 10, 2015.

That said, Gomes concedes that current production figures are lower than they were prior to the recession.

Prime Minister Stephen Harper with Diane Finley, Minister Public Works, and Jeff Watson, MP Essex, sit down with Canadian auto manufacturers during visit to Windsor, Ontario (PHOTO: JASON RANSOM).

“At the peak, we used to produce in excess of three million vehicles [each year in Canada]. Now we’re producing somewhere around 2.4 million. The reality is that we’ve had some plant closures [since] 2000…it’s very unlikely we’ll ever see production close to three million units here in Canada,” he states.

According to Industry Canada, as of early 2015, Chrysler Canada operated two assembly plants in Canada, Ford Motor Company of Canada operated one, General Motors of Canada operated three while Honda of Canada Manufacturing and Toyota Motor Manufacturing Canada each operated two.

Recent news from OEMs in Canada has been mixed. While GM has announced a total of $800 million in new funding for its CAMI assembly plant in Ingersoll, Ontario, it also announced it will be trimming 1,000 positions from its Oshawa, Ontario assembly facilities by year’s end. At the same time, GM says it will spend billions to upgrade certain American plants and modernize Mexican factories. Also in April, Toyota revealed it was planning to move Corolla production from Canada to Mexico by 2019.

On the bright side, Honda recently invested $857 million in its Alliston, Ontario plants. Ten per cent of that total came from the Ontario government. Fiat Chrysler announced in January 2015 it would invest $2 billion in its minivan operations in Windsor, Ontario.

As for the future, it’s a sure bet that automotive OEMs will continue expanding manufacturing operations in Mexico—thanks to lower costs.

Flavio Volpe, president of the Toronto-based Automotive Parts Manufacturers’ Association (APMA), says he’s heard forecasts that Mexico will be assembling over five million vehicle a year by 2020. Such numbers don’t scare him.

Surging Mexican production represents “the best single opportunity for market expansion for Canadian suppliers. Canadian suppliers are very popular in Mexico and very active. We estimate 55 Canadian automotive companies have established 110 facilities in Mexico to serve their customers,” says Volpe.

The APMA has roughly 243 member companies, whose output amounts to over 90 per cent of the volume of auto parts made in Canada. Volpe pegs auto part sector employment at “just under 80,000 people”—a number that’s “been relatively steady in the last couple years, but down from a peak that was probably 25 per cent bigger before the [economic] meltdown,” states Volpe. Annual auto part revenues stand around $24 billion, he adds.

Volpe says Canadian high volume part suppliers are the most obvious candidates for establishing manufacturing divisions in Mexico. Such firms can feed the rapidly growing ranks of auto assembly plants and top tier suppliers in that country.

But what about Canadian automotive suppliers that are either too small or too specialized to set up a Mexican branch?

Now in year two, the Connected Car project is a showcase for Canadian auto innovation and is touring the country this month (PHOTO: APMA).

For them, opportunity beckons from another direction.

In cutting-edge car circles, vehicles that are either “connected” (that is, equipped with elaborate electronics) or “autonomous” (that is, they can drive themselves) are all the rage. Likewise, electric and hybrid cars are rapidly becoming mainstream and there’s ongoing research in hydrogen fuel cell-

powered vehicles as well.

“Canadian suppliers that deal with OEMs with vehicles that have electric drivetrains or hybrid drivetrains or have platforms like [Blackberry subsidiary] QNX’s [operating system] in a vehicle” are in a good position to pitch new connectivity ideas, says Volpe.

Even suppliers who aren’t high-tech can benefit from the new era of “smart” cars. “Connected and [autonomous] vehicles still need suspension, brakes and wheels,” Volpe points out.

The APMA, for its part, has eagerly embraced futuristic cars. The association is now in the second phase of a “connected vehicle” project it launched last year. The project involves a Toyota Lexus RX350 SUV with the latest in high-end communications, infotainment, safety, operating and lighting gear. Canadian firms that assisted with the project include Magna, Lixar, Leggett & Platt, Rogers, QNX Software Systems, the University of Waterloo Centre for Automotive Research (WatCAR), etc. And the Lexus was donated by Toyota Motor Manufacturing Canada.

The connected Lexus RX350 serves as “a showcase of cutting-edge, Canadian value-added, automotive ideas,” says Volpe.

The decked out RX350 will be taken on a tour in mid-June, visiting a series of OEMs and tier one suppliers. The car will be “accompanied by about 20 automotive executives pitching their technology,” says Volpe.

He’s hoping the latter can pick up new business by showing off their wares.

The APMA only has one connected vehicle now, but the plan is to have up to four next year. There have been suggestions of extending the scope of the project to include public transit, Volpe adds.

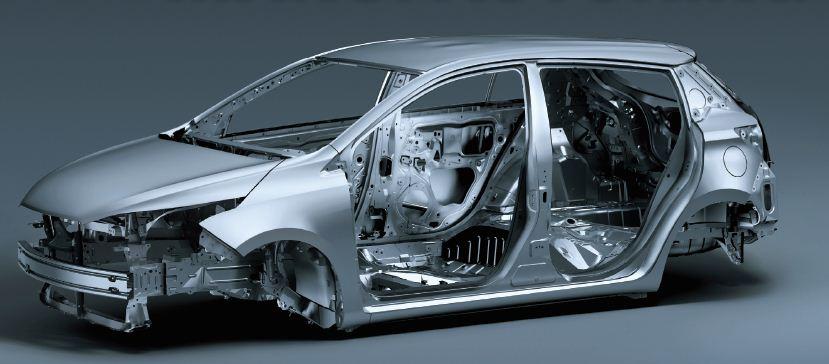

The “smart car” concept fits in nicely with the current mood in Washington, DC and Ottawa. In the United States, strict Corporate Average Fuel Economy (CAFE) rules mandate that all new cars as of 2025 must be capable of achieving 54.5 miles per gallon. This bodes well for automotive companies doing R&D on fuel efficiency or “light-weighting”—simply, making a car as light as possible without sacrificing safety, to ensure maximum gas mileage.

In Canada, the federal government launched an Automotive Innovation Fund (AIF) in the 2008 budget. AIF provided $250 million over five years for automotive firms with large-scale initiatives to design, develop and sell greener, more fuel efficient vehicles. In early 2013, Ottawa announced that AIF would be renewed to the tune of $250 million over five years (2013 to 2018). As a bonus, the Canadian government announced an additional $500 million in AIF funding in the 2014 budget.

The AIF has been joined by Ottawa’s new Automotive Supplier Innovation Program (ASIP). As outlined in the Economic Action Plan 2015, the new fund will provide $100 million over five years to auto suppliers that want to develop and demonstrate new technologies. The ASIP is designed to complement, not replace, the AIF.

The APMA and its member companies strongly supported the ASIP, says Volpe. While the Automotive Innovation Fund mainly benefitted large companies, the ASIP is aimed at small- and medium-sized enterprises (SMEs), he notes.

Innovation isn’t always about space-age technology. J/E Bearing & Machine in Tillsonburg, Ontario, for one, has an innovative service-offering that can’t be offshored to a low-cost locale. Among other duties, the machine shop does maintenance work on equipment and machines in tier one and two auto plants around southwestern Ontario.

The company focuses on “equipment repair and rebuild,” explains vice-president Chuck Hendricks, who cites “conveyors, assembly lines, gear boxes, drives, etc.,” as the kind of equipment they deal with. J/E picks up parts, delivers parts and brings crippled equipment back to life. Sometimes staff fix the problem onsite, while other times they do repairs or make new components in their own facility.

It’s a family-run business with roughly 50 employees. About a quarter of J/E’s work at present is automotive-related.

Equipment maintenance isn’t anything new for J/E (the company has been doing such tasks since it was founded in 1983). Nor is it as profitable as making vehicle components.

“It takes a lot of $5,000 repairs to make up a quarter-million dollar order in production,” says Hendricks.

That said, as long as there are auto assembly plants and automotive suppliers in Ontario, J/E will continue to have a huge pool of potential customers. An emphasis on service has allowed J/E to navigate a sometimes tumultuous manufacturing sector. A sector in which production gains in Mexico and the advent of high-tech cars at home present other opportunities for suppliers that feed into Canada’s auto manufacturing market.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI