- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Demand Attention

Warning Beacons Add a Visibility Advantage to Safety

- By Bryan C. Webb

- March 31, 2016

- Article

- Metalworking

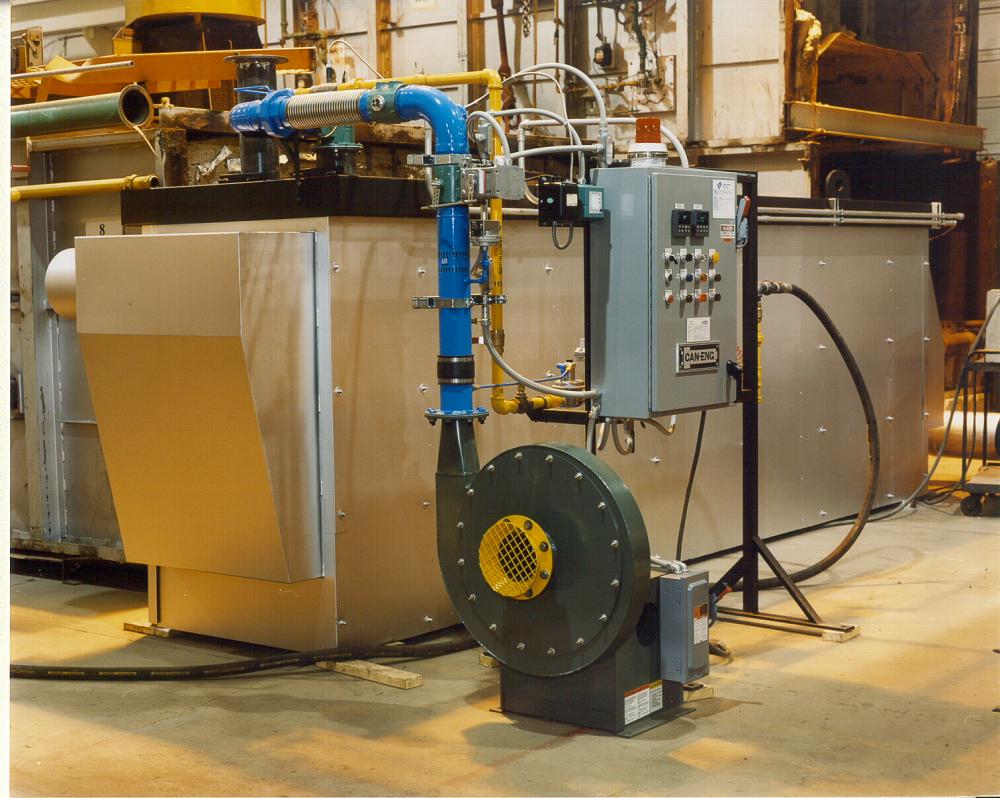

A warning beacon combines flash and audible capabilities to communicate functionality on an industrial furnace.

Safety is a major consideration in all plant facilities, and rightly so. If Ministry of Labour in any province inspects a facility and finds safety violations the fines can be significant and, in severe cases, may result in a directive to shut down until the violations are corrected. This creates an immediate loss of production, sales, and revenue.

Many tried-and-true passive safety assets are—or should be—in place. These include warning signs, stripes on the floor, perimeter fencing/blocks, lock-out/tag-out procedures, plant and personal safety training, personal safety equipment, and documented safety training.

The problem is that these safety procedures are passive. Over time they tend to become invisible or are just plain ignored. In addition, moving equipment such as forklifts and scissor-lifts need to be made visible to everyone. How can employee safety measures be more active and visible to ensure a safer plant? Safety lights.

Catch the Eye

Items to consider when choosing a warning beacon include size, colour, light output (brightness), housing and lens materials, technology, input voltage available, current draw (PLC use), the environment, required approvals, mounting options, reliability, and ancillary features such as selectable flash rate and audible horn.

Size matters since bigger generally equates to more visibility. However, that visibility needs to be balanced with restraints within the environment and location. Standard sizes are low profile (4 in. high), high profile (7 in. or more high), and medium profile with a height between low and high. As expected, the larger the unit, the higher the cost because of added material, but investing in the largest possible option creates the highest level of safety for an installation.

The type of message or warning needed should determine the light’s colour. Although certain colours typically have accepted meanings, there are no industry standards or regulatory demands, so each company is free to choose its own. The key is to be consistent within the plant.

Brightness and Durability Count

Functions of an industrial quenching operation are communicated visually and audibly with an LED warning system.

Light output level is key for visibility. The brighter the light, the more likely it will be seen and catch attention even from a distance. Unfortunately, some manufacturers do not list the light output or they choose a measurement that is not useful for comparison. For modern LED designs, output should be in the 400-700 lumens (lm) range before considering the reduction effect of the lens colour. For older strobe units, 10 joules is a common value; halogen rotators define output in watts.

Materials influence reliability and approvals. Generally, a metal base will be more rugged than a polycarbonate, which is better than acrylic. Some approvals, such as Class 1, Division 1, require a metal base to better contain internal problems. As for the lens, polycarbonate is tough and resilient, but additional protection may be added with either a polycarbonate, hardened glass dome or a metal guard. Environmental issues can be resolved by getting units that conform to IP66 for either inside or outside use.

Available technologies include halogen/mirror rotators, high-voltage circuit strobes, and modern LED systems. Properly designed LED units manage the heat that is generated while driving the LED to maximum output for a bright light. LEDs have are no bulbs that break or die and need replacing. When a bulb dies, the warning ability is unavailable.

Voltages are usually determined by the control system requirements but LED units are often available with wide inputs, from 10 to 125 VDC or 90 to 240 VAC plus specific industry needs (300 VDC). Older designs may have very narrow ranges: 12 VDC ±10 per cent, 24 VDC, 120 VAC, 240 VAC, and so forth. Strobe units can draw a very high inrush current while the capacitors charge. This is hard on some PLC or control systems. LED designs never have excessive current draw as they have no large capacitors so no inrush.

Approvals Are Key

There are two types of approvals: electrical grid acceptability and operational safety. In Canada, the grid approvals typically come from CSA, UL/ULC, or ELT and may be specified for multiple countries. For example, a cCSAus designation means that CSA has tested and approved the device for operation in North America and the product has the right to bear that mark.

For operational safety, you may see something like Class 1, Division 2 or Zone 1 that permit use in hazardous locations. Basically, the unit is tested to ensure it will contain any flames or debris from an internal fire so that it does not make the situation worse within the plant. Should you choose wrong, a product that is not CSA-approved, your plant insurance may be void.

Depending on the area to be covered, the method of mounting may also be important. Many units can be surface-mounted or used in conjunction with a standard electrical junction box. Others may be pole-mounted using standard ½-in. or ¾-in. NPT threads. Options may include wall or corner mounts and secondary securement using a wire cable. Magnetic-mount options are available but a unit can fall off if it’s mounted on a quickly moving surface.

Make Valid Comparisons

Other considerations include the flash rate, which can be between 60 and 160 flashes per minute; how the rate is selected; and options such as an audible horn. The sound spec should include distance, for example, it should be written as 85 dB at 1 meter as sound pressure level without distance is an incomplete measurement.

Finally, consider the reputation and reliability of the manufacturer. A five-year warranty is the norm for LED technology. Product price should be the last consideration once you’ve selected the right product for the job.

Typical Colour Meanings

Although no industry standards currently dictate warning light colours, several have generally accepted meanings:

• Amber—Running or operational; no faults such as over-temperature or pressure warnings

• Blue—Batch complete; help request for additional materials or maintenance

• Clear/White—Setup error; user-defined conditions often relating to productivity monitoring

• Green—Running properly with no issues; normal machine or process operation

• Magenta—Biologic or organic fault or spill

Internal circuits of an LED-based warning beacon are potted with epoxy to protect against vibration, moisture, and dust.

• Red—System fault, production halted; failure conditions such as emergency stop or machine fault

Bryan C. Webb, P.Eng., is industrial sales manager, Safety Warning Specialists, 905-357-0222, www.swscanada.com.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI