- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

CMTS 2015 Preview: Flexarm Inc

Check out Flexarm in booth 1316.

- September 3, 2015

- Product Release

- Metalworking

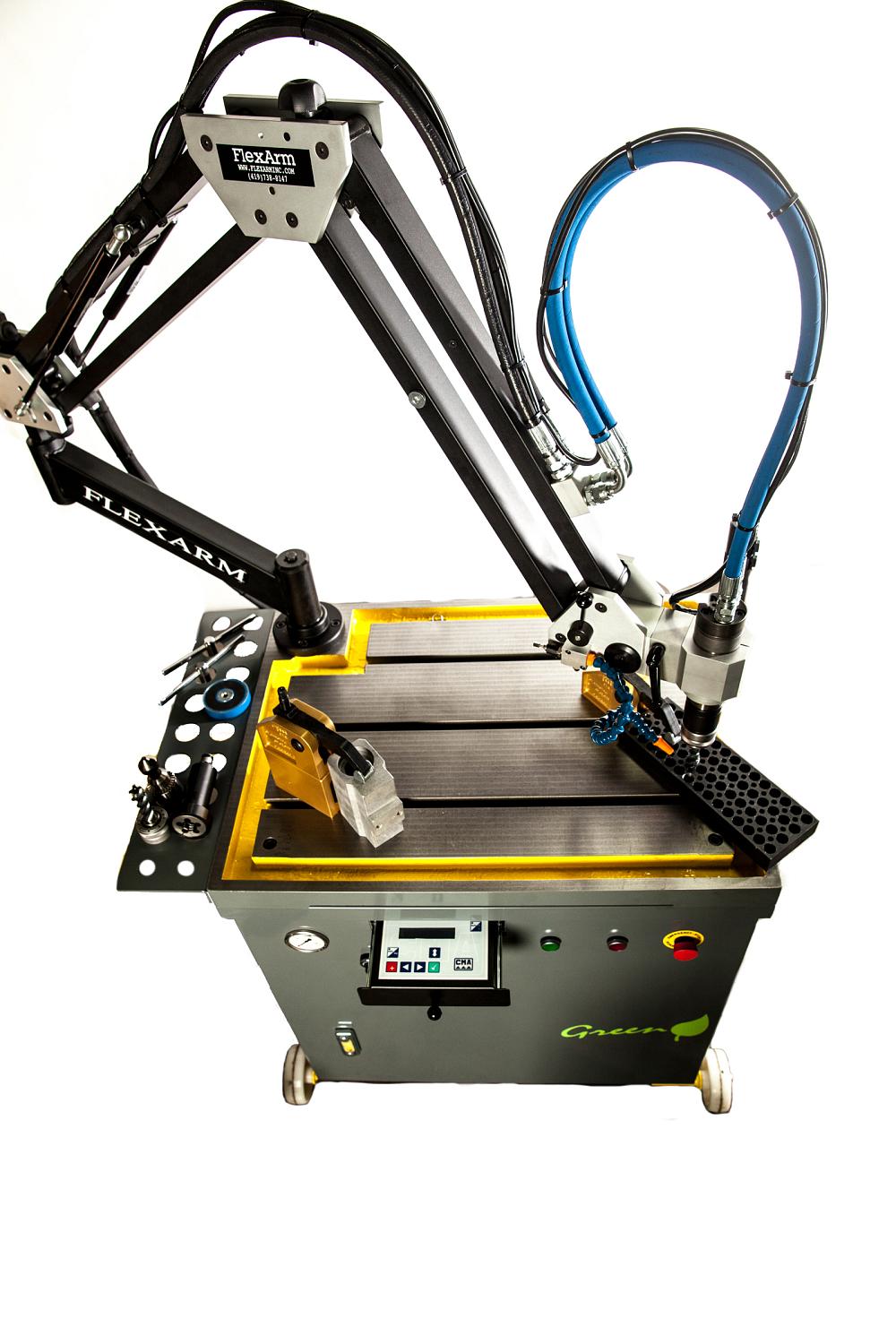

FlexArm Inc. will be showing off its latest technology in booth 1316 at CMTS 2015.

The company is offering power and speed with their new line of Hydraulic Tapping Arms.

By running tapping and threading operations offline while a CNC is running, an operator can increase efficiency and improve cycle times.

“Tapping 1-1/2” in mild steel at 110 rpm is not something most machines can do," says Nick Kennedy, President of FlexArm. "We are able to achieve this with our new Hydraulic Power Packs and unique gearboxes. Our machines are designed to create a lot of torque with speeds that cannot be achieved using other methods.”

Tapping with a FlexArm while a lathe or mill is running eliminates tapping and thread milling operations. It takes tapping operations off CNC machines to drive more efficiency in machine tool use. Incorporating this technology with CNC machines reduces cycle times and supports overall equipment effectiveness in a machining center.

Designed to quickly go forward and reverse, a FlexArm Hydraulic Tapping Arm is made for tapping, not simply running in one direction like the spindle of a CNC Mill. FlexArm Hydraulic Tapping Arms allow customers to program their exact RPM for forward and an exact RPM for reverse. Whether an operator needs to run 30 RPM to pull a large ACME tap or 500 RPM to quickly tap 7/8”, they have the flexibility for increased efficiency.

This new line of FlexArm tapping solutions also features programmable depth control, allowing for consistency in tapping depth.

For more information, visit www.FlexArmInc.com.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI