- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Software improves efficiency, speed, accuracy of production machining

- July 21, 2016

- Product Release

- Automation and Software

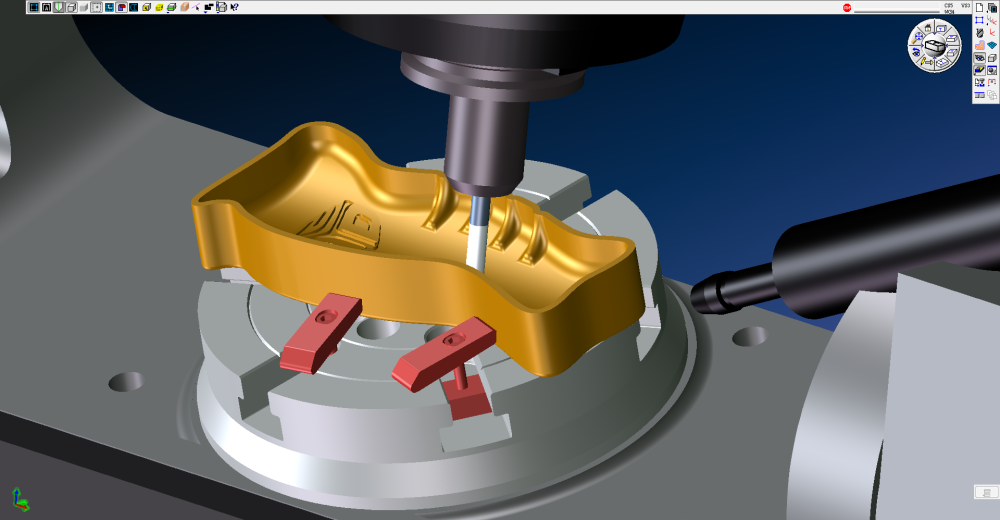

3D Systems has released GibbsCAM® 2016, a software package for production machining.

This software delivers a variety of improvements to increase efficiency, accelerate programming speed, and enhance visualization and accuracy for CNC machine programming, the company states.

The enhanced kinematic framework makes it a suitable CAM platform for nearly every manufacturing environment. It is compatible with numerous programming and machining operations, including solid modeling, high-speed machining, 2- to 5-axis milling, wire EDM, and multitask machining.

New features and functions include:

- Enhanced thread milling, including support for multipoint tools, tapered threads for both single- and multipoint tools, and improved simulation.

- The latest VoluMill™ technology for new toolpath strategies optimizes high-speed roughing of large pockets and slots, open face milling strategies that can decrease cutting time by up to 60 per cent, and Technology Expert integration for ready access to optimal speeds and feeds.

- New oriented turning capabilities give users added control in how tools interact with parts. This includes using a single tool at multiple B orientations and reorienting tool groups for use on a different spindle.

- Added toolpath strategies for 5-axis milling enable programmers to define toolpath direction using the natural flow of a surface with the new Flowline option. Toolpaths can also now be extended in width as well as length. Additional enhancements include improved 5-axis drilling, multistepped pocket roughing, and new gouge checking strategies.

3D Systems * 803-326-3900 * www.3dsystems.com

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI