- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Vero Software releases Alphacam 2016 R1

Parametric Sketcher, File Inserter, and 2D Transform have been added to make further operations quicker and easier.

- November 25, 2015

- Product Release

- Metalworking

A number of new and enhanced items in the latest release of Alphacam software focus on automation, reducing users’ CAD/CAM time.

The new Automation Manager means 2D and 3D Cad files, along with solid models from third-party software, can now be batch processed, from file preparation right through to applying toolpaths, with NC code being generated automatically. In addition, the files create a full report structure, along with labels and bar coding.

Three additional enhancements—Parametric Sketcher, File Inserter, and 2D Transform—combine to make further operations quicker and easier:

Parametric Sketcher provides a simple way of parametrically generating geometries for files that are used regularly, without the need for complicated constraints or routines.

File Inserter, the new geometry creation tool, allows pre-defined elements, such as hinges and locks on a door, to be inserted easily onto a newly created drawing from the parametric sketcher. And the new geometry modification tool, 2D Transform, combines a number of commands, making it simpler to manipulate operations such as distort, scale, move and rotate.

With machine time becoming increasingly more expensive, Alphacam 2016 R1’s new Auto-Update Material function is critical, giving the option to associate a material to auto-update after each cutting operation.

Enhanced sawing options for wood and stone make it easier to cut intricate shapes such as internal arcs, while also providing a scratch cut for laminates, removing pockets with a sawing blade, and support for canned cycles.

As CNC machinery becomes more sophisticated Alphacam continues to develop automating the movement of pods, rails and clamps.

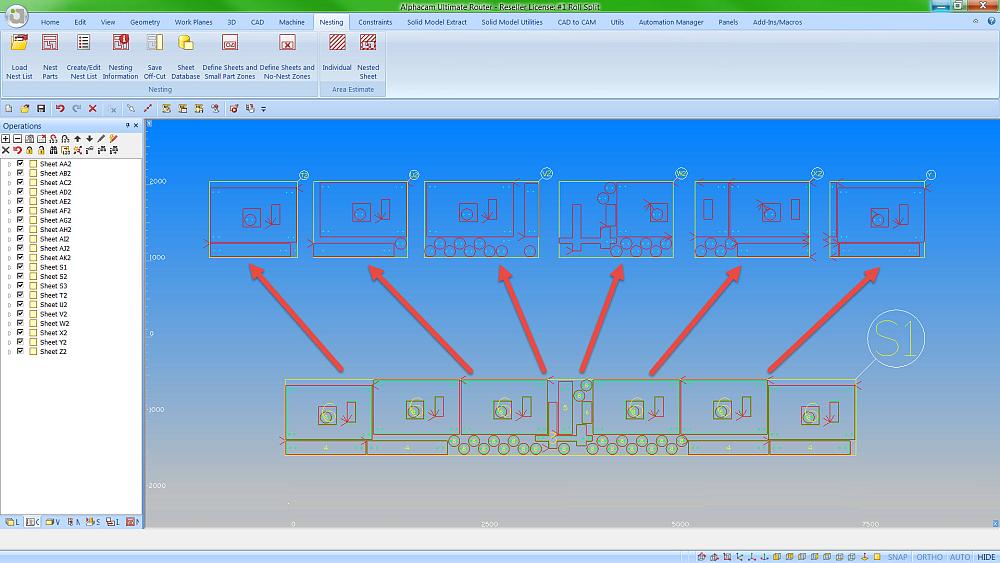

A new function has been added to Alphacam’s powerful nesting module—Roll-Split. Manufacturers need to nest shapes onto rolled sheets, so the nest can be quite long. In 2016 R1 they can now split the roll to the required dimensions for a specific machine bed. The parts are nested on a sheet which represents the length of the roll required as a long rectangle. Maximum and minimum distances are set, and Alphacam determines the best position for the sheet ends.

With increasing complexity, both of modern parts and CNC machines, accurate simulation covering all aspects of machining is vital before sending the component to the machine. Further enhancements have been added to the simulation function, which now supports solid tool holders of any type—Solid, STL, extrusions and rotations—for collision detection.

Alphacam continues to develop its GUI with 2016 R1. There’ve been significant changes to the interface in recent releases, and we always make it as easy and as modern as possible. Users now have the option to use a tab format or wizard when using the machining dialog.

As well as the major updates, there are a number of minor enhancements, including further improvements to Alphacam’s advanced 5-axis toolpath creation; one of which is to Machining Styles, which now remembers the selection criteria without showing the dialog box. Also, layer assignment has been added to the drive surface.

For more information, visit www.verosoftware.com.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI