MTB Project Manager

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Make a strong connection

Connecting a new generation of tools with a new generation of machining centres

- By Joseph Polyanovsky

- October 15, 2018

- Article

- Cutting Tools

Modern industry demands fast and effective systems for mass production. The new generation of multispindle machining centres responds to this need by increasing productivity through the simultaneous machining of two to four workpieces.

Tooling suppliers have correspondingly developed tooling for this type of machine to help ensure precision and quality with minimal setup time.

Tooling manufacturers must also adapt to developments in the aerospace, aviation, and medical industries that have necessitated machining high-temperature or exotic materials with maximum efficiency. In particular, the application of coolant with high (or ultra-high) pressure, directly to the working area to increase efficiency and chip flow, requires a suitable tooling package.

Vertical pickup turning machines have wide applications for manufacturing of automotive, hydraulic, and general industry parts, and their value in maximizing efficiency should not be underestimated.

Multispindle machining centres save space at a manufacturing facility and can reduce tool inventory by using combined tools for sequential operations and decrease setup time by assembly and adjustment of the same tool for each spindle.

The principal reason for using multispindle machines without Z-axis compensation is to facilitate the axial adjustment needed to achieve overlength precision. This ensures part repeatability over all spindles and reduces cutting time, because a more precise cut pass is made.

Several methods can be used to accomplish the goals of precision and high output.

Spacers. These are commonly applied on face milling cutters to provide a simple technique for length adjustment.

Adjustable wedges. Wedges can be used for fine turning of overlapping (sometimes in addition to spacers) and are commonly used for face milling during the finishing operation.

Cartridge adjusters. Tools now exist for drilling or boring operations, with exact hole depth, and which can be adjusted by cartridges (see Figure 1). There is also an option for radial adjustment. For simple solid-carbide drills, the tool can be mounted on an adjustable holder.

Complex tools. Tools that incorporate different types of instruments, which can be combinedly adjusted by some (or all) of the aforementioned methods. Figure 2 shows an example of a tool that performs drilling, chamfering, and slot milling and is regulated by a spacer, wedges, and preset screws.

The adjustment of complicated technical systems to meet customer requirements necessitates additional time and human resources for assembly and fine-tuning procedures.

In general, multispindle machine tool builders prefer to deliver all-inclusive systems for initial equipment or turnkey projects. These comprehensive plans save time and cut down on the human resources required for startup procedures, especially for large projects. A tooling supplier should provide completely assembled, adjusted, and balanced tools.

MQL Applications

Minimum quantity lubrication (MQL) technology is widely applied in multispindle machine tools because it circumvents the problem of liquid leakage from the machine and does not require additional equipment for coolant return. MQL helps to maintain the machine’s condition during continuous usage; improves chip quality, evacuation, and recycling; and represents a “green” technology for a healthier environment.

Tools working with MQL have a different design and different accessories than tools that work with conventional coolant.

Tools With High-Pressure Coolant

Applying high-pressure (HP) coolant in grooving and parting operations provides excellent chip-breaking results on all materials, reducing or even eliminating built-up edge (BUE), particularly when machining stainless steel and high-temperature alloys.

To harness these capabilities, tooling suppliers offer tools for turning and grooving and parting applications with high-pressure coolant, with different sizes, adaptors, and machine interface connections.

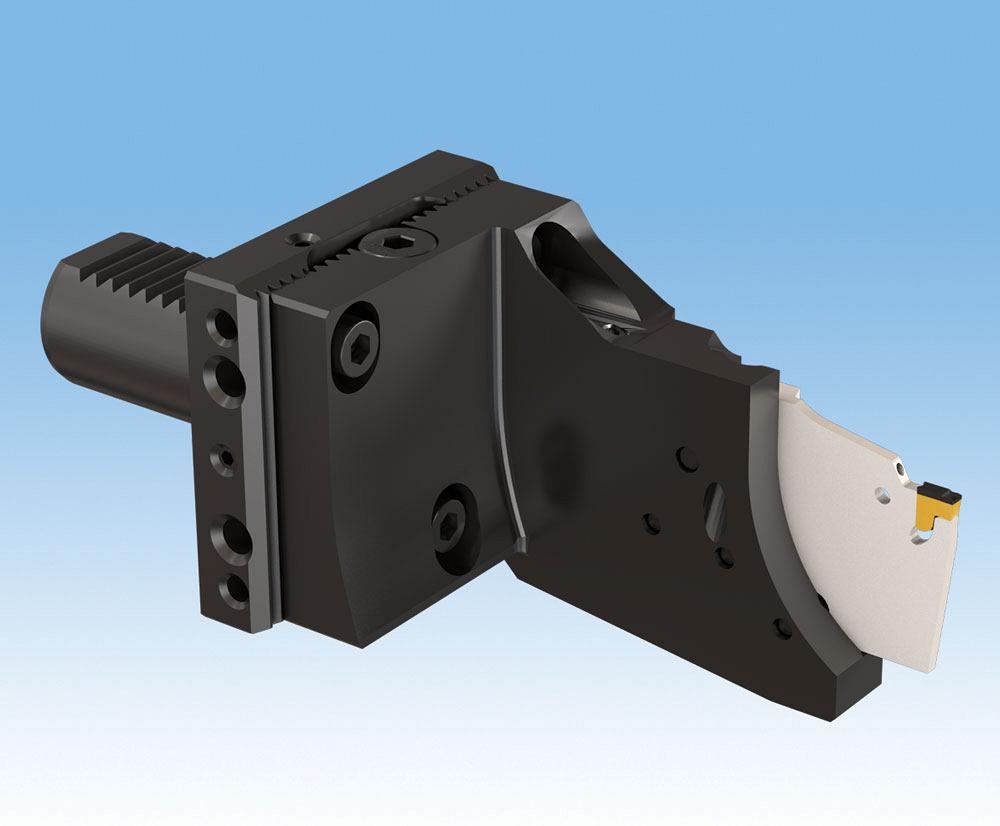

For example, Iscar’s Modular-Grip systems for high-pressure coolant were developed to reduce tooling costs and inventories. Cooperation with machine tool manufacturers led to the development of standard lines of dedicated tools for each builder’s interface, such as VDI, dove tail (DT), Capto®, and other specific interfaces (see Figure 3).

Ultra-high-pressure (UHP) coolant tools facilitate effective machining of titanium and heat-resistant materials used in the aerospace industry, to achieve high machining rates while producing small chip sizes.

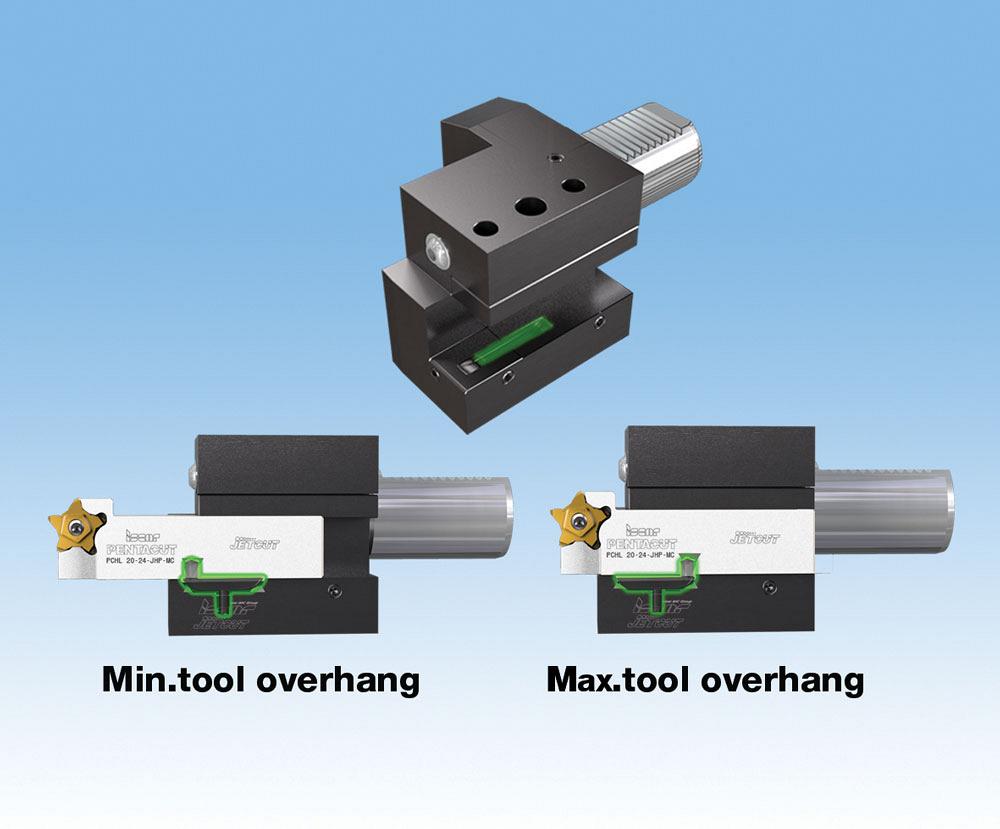

CNC turning machines with disc-type turrets use different interfaces and often require adjustment of the tool’s overhang, as shown in Figure 4. Multiconnection tools enable clamping on quick-change toolholders and also directly on the turret with different coolant connections. Tools with a jet high-pressure (JHP) coolant outlet also deliver an advantageous performance when conventional pressure is applied.

Using Capto Connections Without an ATC

Vertical pickup turning machine turrets can be equipped with instruments without an ATC (see Figure 5), which enables tools to be manufactured with as short an overhang as possible. This in turn increases machining process rigidity and stability and lowers tool production costs.

Joseph Polyanovsky is MTB project manager for Iscar Tools, www.iscar.com.

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

CTMA launches another round of Career-Ready program

Collet chuck provides accuracy in small diameter cutting

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI