- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Manufacturers drive coatings forward

New materials, lights-out manufacturing, and advanced processes demand new formulas

- By Sue Roberts

- December 6, 2017

- Article

- Cutting Tools

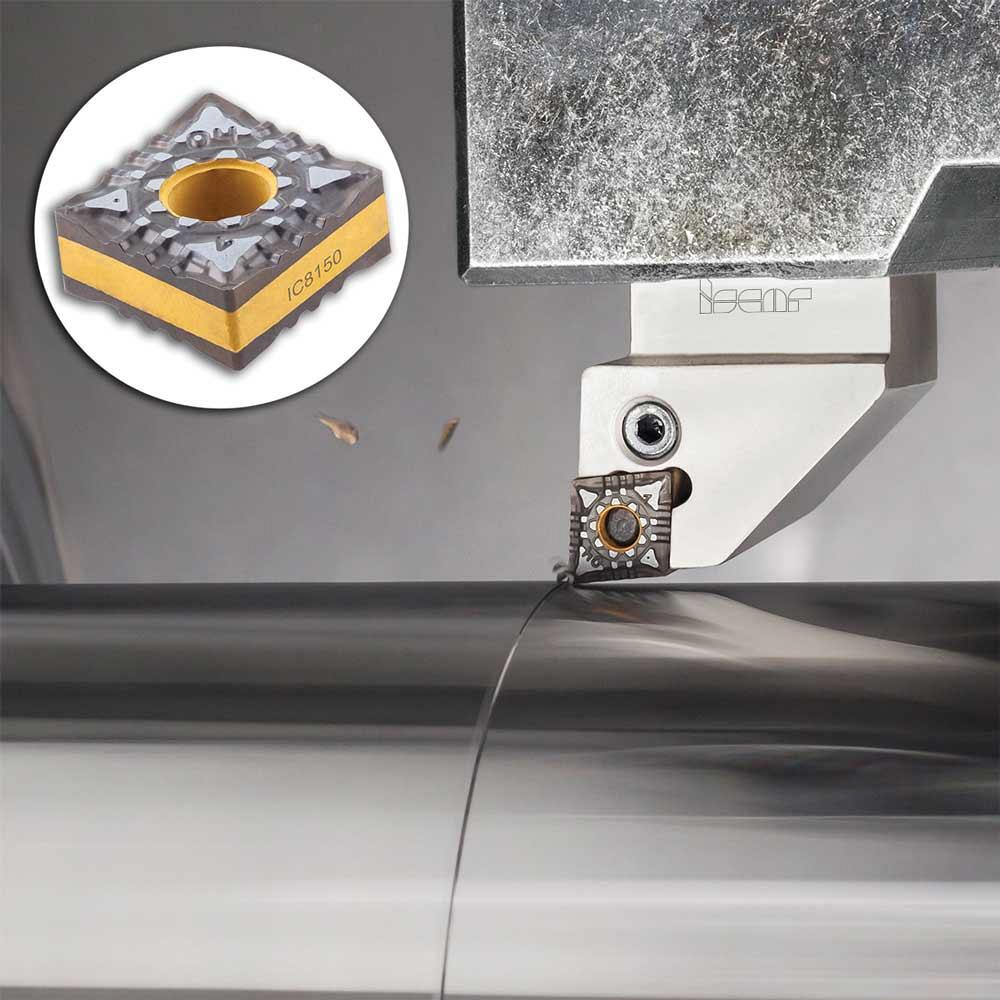

Coatings like Sumitomo’s CVD Absotech Platinum are designed to increase cutting speeds and improve cuts in carbon steels, tool steels, and stainless steels. Photo courtesy of Sumitomo Electric Carbide Inc.

Follow that path only if you want to lose productivity today.

Insert manufacturers, like electronic providers that continually upgrade cell phones and televisions, continually invest in research and development to make their cutting tools do a better job. The upside to not staying with the coating developed a few years ago is that new, more effective coatings add more to the bottom line. The downside, which isn’t really a downside, is that there are many more options to choose from which can make selecting the right cutting tool a bit difficult. Experts at each tooling company save the expanded options from being a problem. They will collect information on the process being used, the material being cut, and the end product being produced to be sure the right coating is selected to provide quality cuts and long-lasting performance.

Every shop’s desire is to increase production without losing quality amidst faster machining processes. Lean manufacturing remains a common goal. Lights-out production requires inserts that last until an operator returns to change edges. A job shop gets a job that requires working with a new, difficult material. Chances are the best insert and coating to be used is not an old reliable. These are the types of situations that drive coating research forward.

John Copher, applications engineer at Sumitomo Electric Carbide Inc., said, “Part of my job is answering the engineering hotline, and almost every day someone calls and says they are working with a material we have never heard of before. As a tooling provider, we have to find out what is in the material and work with the caller to assign the grade and coating that will work best. All the old materials are still out there, but there are a lot of new materials in the aerospace, automotive, and medical fields that have caused us to adjust the technology that produces the coatings on the inserts that will cut those materials.”

3 Main Types

Steve Geisel, senior product manager at Iscar Canada, said that there are three main categories of coatings: chemical vapour deposition (CVD), physical vapour deposition (PVD), and uncoated. CVD coatings are generally thicker and allow machining at higher surface footage, which can be good for machining carbon and alloy steels. PVD coatings are for the high-temperature alloy materials because the coatings are very thin to allow the insert to absorb heat. That quality avoids work hardening that would be caused by heat reflecting back into the cut or chip. Uncoated inserts are used for high temperature applications like titanium because many of the coatings have a titanium layer and the cutting tool needs to be harder than the material being cut.

Advances are continually being made in all three categories.

Uncoated inserts, along with the CVD and PVD coated inserts, benefit from new substrates. For coated inserts, new chemical formulas continue to make them last longer, be more efficient, and have the ability to cut established and new materials faster.

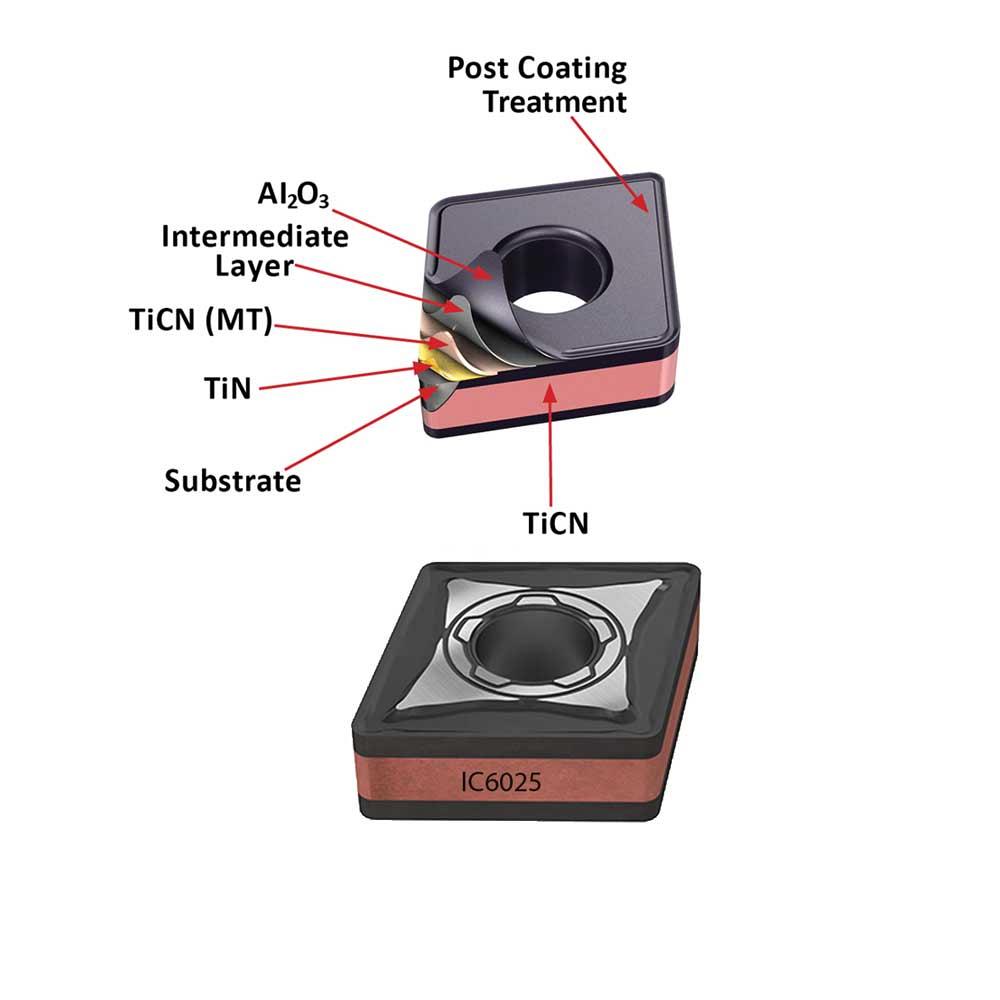

Most of the coatings, nearly 90 per cent according to tooling manufacturers, are multilayer. The elements making up each layer, the thickness of each layer, and the order in which they are applied to the insert dictate what materials they can cut and how long they will last.

Tooling manufacturers continually experiment with new mixes of standard coating materials and introduce new elements.

“We are starting to use coatings that incorporate rare-earth elements to try to get the coating at a higher hardness than the material being machined,” said Geisel.

Iscar’s grade IC6025 structure is for turning ISO M materials. Each layer of the coating and its thickness are chosen to meet a specific need. Photo courtesy of Iscar.

The Shape of Atoms

Structure of the atoms within the coatings and how each coating adheres to the layer above and below also plays a large role in their effectiveness.

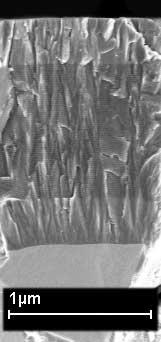

Aaron-Michael B. Eller, product manager—ISO turning and advanced materials, Seco Tools LLC, said, “In PVD aluminum titanium nitride or titanium nitride coatings, the atoms are arranged in a cubic form. During use, structural and compositional changes take place. Some are helpful but others are not. By controlling the coating process, we can encourage the good and deter the bad, resulting in increased speed capability and wear resistance.

“In CVD aluminum-oxide coatings, the atoms are arranged in a hexagonal form. In the past the orientation of the coating’s building blocks were randomly arranged. Today we can control the orientation and bring a harder and tougher structure to the point of the cut. These textured coatings are 15 per cent tougher and 10 per cent harder than the old version. That means as much as 20 per cent more cutting speed or 30 per cent more tool life.”

Copher said the ability of tooling manufacturers to control the crystal orientation keeps the coatings in line with each other. “Controlling the crystal orientation helps the wear resistance, the peeling resistance, and the breakdown of the coating during the machining process.”

Visual Advantage

A top layer of coating such as a colourful chrome that wears away to expose the different colour of the layer below can, by itself, provide a significant increase in productivity.

“We did a spot check with some of our customers. We would go to a recycle bin, grab a handful of inserts, and check the edges. They were shocked at the number of unused edges that were thrown into the bin,” said Eller. “Simply having used edges visually apparent in contrast to unused edges made it easy for operators to use all edges before tossing an insert. It creates a substantial cost savings.”

Some Recent Coatings

Understandably, many of the new coatings have been developed to increase production in exotic and difficult-to-machine materials, but not all. Some new coatings boost production for established, more common materials.

Iscar’s DO-TECH coating combines the CVD and PVD technologies to create a coating that improves performance when cutting cast iron for milling and turning. Geisel said, “We use a lot of titanium carbides and aluminum oxides. We also use titanium nitride—it’s a good coating to use as a top layer because it’s gold and shows the wear.”

Sumitomo’s CVD Absotech™ Platinum coating is a multilayer aluminum oxide/titanium carbon nitride designed mainly to cut carbon steels, tool steels, and stainless steel. Copher said that the Absotech Bronze PVD coating of titanium aluminum silicon nitride is recommended for interrupted machining of stainless steel and exotic materials.

Duratomic® from Seco is a CVD aluminum-oxide coating for increased edge toughness, more wear resistance, and smooth surface finishes that are cut with less friction, said Eller. When the insert does begin to wear, the chrome included in its makeup shows the worn edges.

Each layer of a nanolaminate PVD coating is approximately 7 nm thick. Varying the individual layer materials and thicknesses makes it possible to adjust the hardness and thermal stability properties. Photo courtesy of Seco Tools LLC.

Everything Matters

“Whenever we’re working with a manufacturer, we have them show us the machine to be used, specify the material, and show us the workpiece. The workpiece itself is key. Is it an easy shape or some sort of irregular shape that needs counterweights because the part might not run perfectly true? A prime example is the automotive industry because its parts might have lobes or protrusions so they have to be offset when they run. That affects the insert wear. We get a feeling for what type of cutting parameters they can operate safely and then determine the insert and coating. If you run too fast, you can risk throwing a part out of a machine and hurting the operator,” said Geisel.

“I’ll ask manufacturers why they are using a particular insert or coating and they say, ‘It’s just what we had.’ That’s understandable if they have only a few pieces to make, but they need to understand that all tooling manufacturers are improving technologies,” Geisel said. “A grade of coating they used 10 years ago is completely different from today’s grades which are much better.”

Iscar Canada, 905-829-9000, www.iscar.ca

Seco Tools LLC, 248- 528-5457, www.secotools.com

Sumitomo Electric Carbide Inc., 800-950-5205, www.sumicarbide.com

About the Author

Sue Roberts

2135 Point Blvd

Elgin, IL 60123

815-227-8241

Sue Roberts, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. A metalworking industry veteran, she has contributed to marketing communications efforts and written B2B articles for the metal forming and fabricating, agriculture, food, financial, and regional tourism industries.

Roberts is a Northern Illinois University journalism graduate.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Identifying the hallmarks of a modern CNC

CTMA launches another round of Career-Ready program

Collet chuck provides accuracy in small diameter cutting

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI