- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Technology spotlight: Toolholders

New toolholding products mirror modern metalworking demands

- By Canadian Metalworking

- May 3, 2019

- Article

- Cutting Tools

Toolholders act as the interface between the cutting tool and machine, and they should ensure proper clamping of the cutting tool and also be suitable for mounting in the fitted spindle or tool changer magazine.

The metalworking industry has compulsory standards to strictly specify the matching surfaces for both of these purposes. These standards define a range of existing tooling systems to meet different manufacturer requirements, including simple holders on manual tool changing for conventional machines with hand controls and precise, high-grade-balanced adapters for high-speed machining centres.

The variety of toolholding systems provide the manufacturer with multifold options for effective toolholding, depending on production targets and available machinery. This is why toolholders reached a certain level of excellence that did not require groundbreaking changes.

Today modern tooling is evolving along with metalworking industry developments in Industry 4.0. Manufacturing digitization also plays an important part in the development of new tooling features.

Advances in high-speed machining (HSM) exemplify the cause and effect of these changes. Implementation of new technologies in HSM has necessitated a new level of tool balancing to ensure toolholder performance and reliability in a significantly expanded range of rotational speeds, with the objective of improving strength, rigidity, accuracy, and other technical parameters of traditionally designed toolholders.

High-efficiency milling of difficult-to-cut aerospace materials, like titanium alloys, also has increased demands for durable toolholders working in hard conditions.

Iscar Tools sells a variety of arbors, holders, adapters, blocks, and thermal and power chucks for effective tool clamping.

Following industry demands, performance parameters for these parts have been tightened up significantly. For example, the company’s Shrinkin thermal shrink chucks with HSK 100 shanks now feature G2.5 balance quality and a residual unbalance of less than 0.00139 oz. in. at 20,000 RPM; Maxin 32 power chucks ensure clamping torque up to 1,300 lbf. ft., and Finefit radial and angular alignment toolholders for high-speed reamers maintain radial and axial runout adjustment to 0.00004 in.

Clamping and cooling

Iscar recently launched a series of new tooling families that provide pinpointed coolant supply. In many cases, like machining titanium or exotic high-temperature superalloys (HTSA), which are common for the aerospace industry, cooling is a critical factor of success.

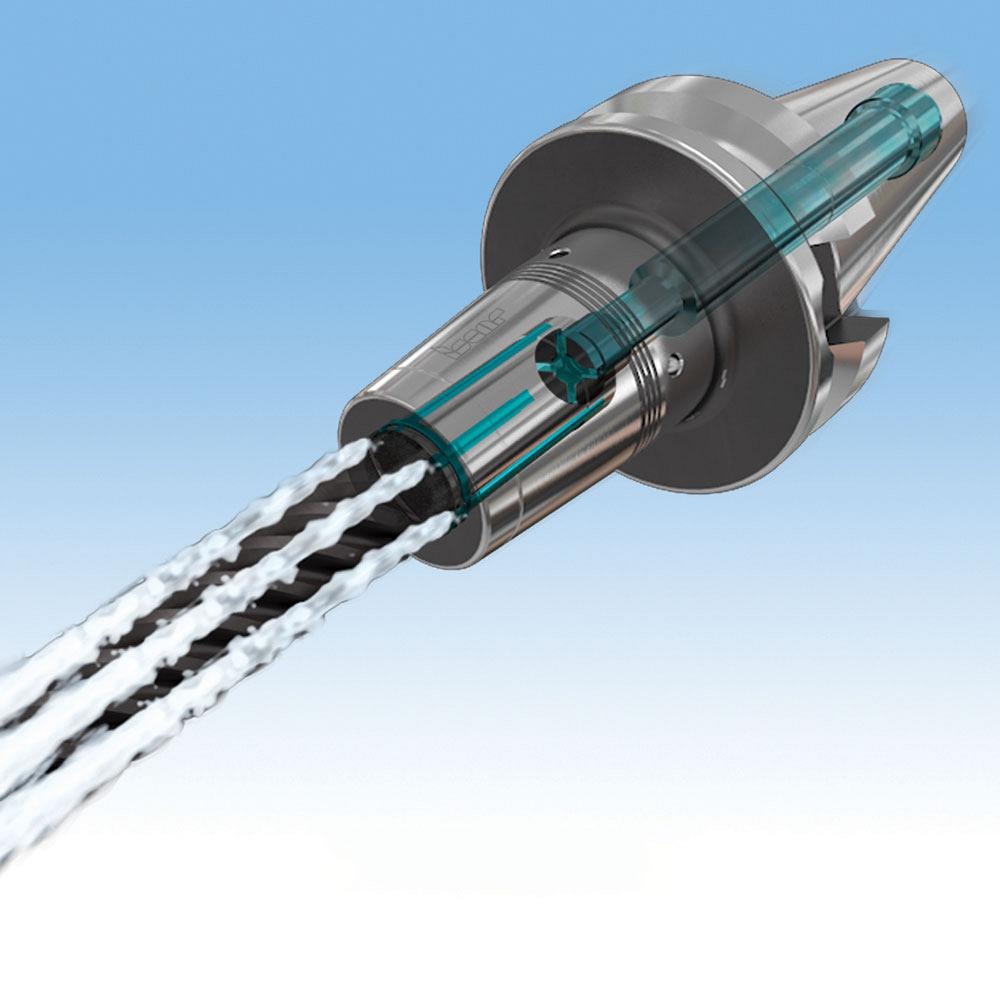

X-Stream Shrinkin is a family of thermal shrink chucks with coolant jet channels along the shank bore (Figure 1). The family uses a patented design for holding tools with shanks made from cemented carbide, steel, and high-speed steel (HSS).

New chucks combine the advantages of high-precision heat-shrink clamping with coolant flow directed to cutting edges. This system is suitable for milling aerospace parts, particularly titanium blades and blisks, and for high-speed milling. During machining of deep cavities, the cooling provided by the new chucks substantially improves chip evacuation and diminishes chip re-cutting.

Turning system

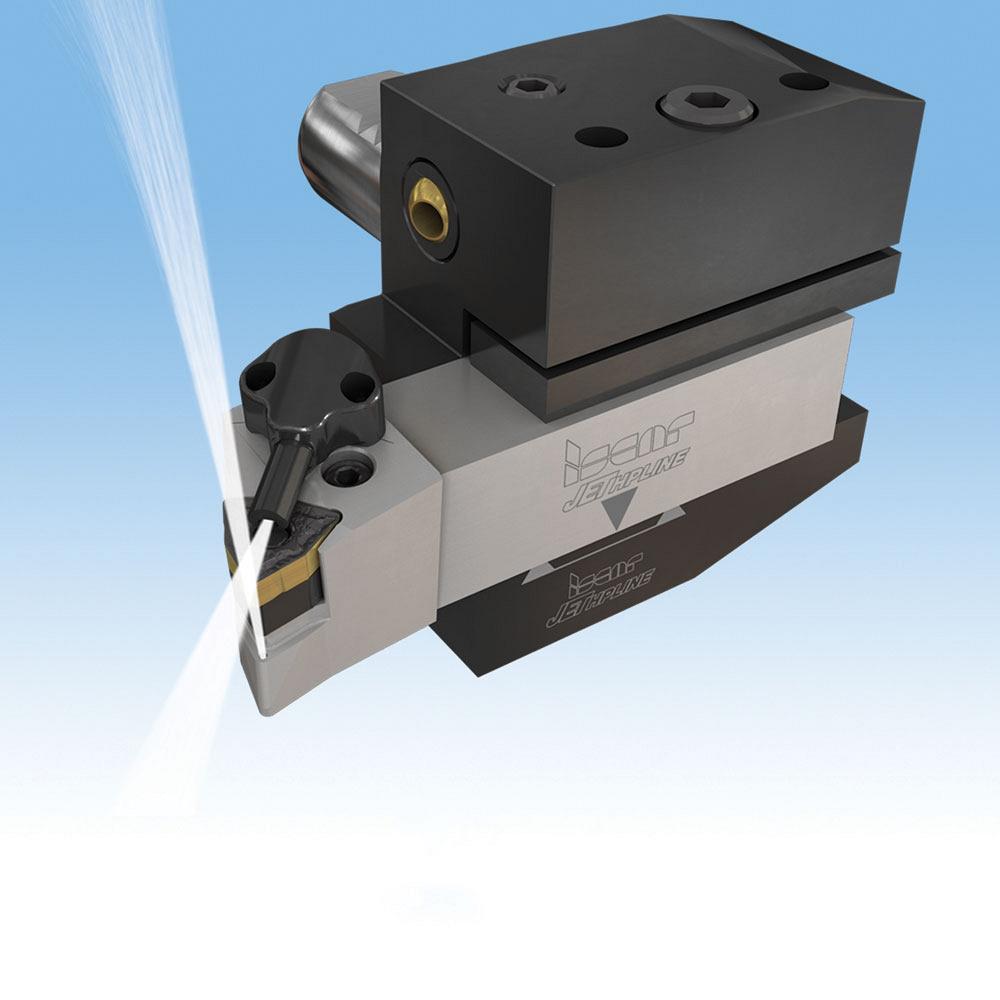

For turning applications Iscar has developed a new concept for high-pressure coolant (HPC) supply for VDI DIN 69880 quick-change adaptation systems.

The JetCut concept is based on bottom-fed HPC channels (Figure 2) and provides coolant supply internally through the tool and externally through the flange. The resulting cooling effect improves performance in turning, grooving, and parting applications.

Coolant can act as an excellent tool in a radically different field: increasing the rotational speed of a tool. The SpinJet family of coolant-driven, high-speed, compact spindles for small-diameter tools is a type of “booster” for upgrading existing machines to high-speed performers (Figure 3).

The spindles are recommended for tools up to 0.275 in. diameter; however, the optimal diameter range is 0.020 to 0.157 in.

Depending on pressure and coolant flow rate, the spindles maintain a rotational speed of up to 55,000 RPM. These products have been integrated in milling, drilling, thread milling, engraving, chamfering, deburring, and fine radial grinding applications.

Reaming product

In reaming applications floating chucks are used in high-precision holemaking to correct any misalignment between the central axes of a reamer and the hole. Precise alignment is essential for optimal performance and hole accuracy.

New GFIS floating chucks for high-speed reamers have been added to the ER collet chuck family (Figure 4). The new chuck integrates technology that helps to ensure that the system remains completely rigid until it reaches a steady state of reaming.

Industry 4.0

The Industry 4.0 concept of data-driven smart manufacturing has had a direct impact on the entire chain of production, including the seemingly conservative field of toolholding.

In a smart factory, production systems perform under the conditions of real-time mutual information exchange. Modern toolholders incorporate holes for radio frequency identification (RFID) chips. Computerized tool storage units read the RFID chips and the machine automatically receives all necessary identification data from the toolholder.

Despite a conservative reputation, the latest toolholding product innovations both reflect and reinforce the trends of metalworking today and beyond.

Iscar Tools, 2100 Bristol Circle, Oakville, Ont. L6H 5R3, 905-829-9000, www.iscar.ca.

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada

DiPaolo Machine Tools Open House 2024

- June 4 - 5, 2024

- Mississauga, ON Canada