Associate Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Automating bending operations improves press brake performance

Today’s fabricators look to automation to deal with complex parts, shorter batches, and reduced lead times.

- By Lindsay Luminoso

- August 10, 2018

- Article

- Fabricating

With trends like Industry 4.0 and IIoT, fabrication shops are looking for new ways to increase productivity and profitability. With the addition of new technology on the shop floor, bottlenecks can occur down the production line, specifically at the bending stage.

“You can often get bottlenecks at press brakes, and you might just think that a good solution is to buy more press brakes,” explained Paul LeTang, product manager of press brake/tooling at Bystronic Inc., Elgin, Ill. “But with the economy and the workforce, it can be very difficult to find skilled press brake operators. The industry trend is to improve the performance of the press brake, not just to simply add more press brakes.”

One way to improve production performance is to decrease bottlenecks in the production cycle. Because bottlenecks often occur at the press brake stage, adding automation to a press brake can alleviate this stress and increase productivity.

“Fabricators who are considering integrating automation into their bending process are looking for ways to maintain consistent quality, process varying batch sizes—not just large quantities—and have the capability and the confidence to run lights-out to be more productive and profitable,” said Steven Lucas, press brake product manager, LVD Company, Akron, N.Y. “Factors that influence this include labour cost, the drop in skill level on the shop floor, the scarcity of press brake operators, and the need to improve productivity. It’s all about lowering the direct cost per part and maximizing throughput.”

Buying a new piece of equipment, like a press brake, can help ramp up production on the shop floor. Investing in new technology is great, but shops need to ensure that they are getting the most out of their investment. When a machine is idle, whether it is due to worker shortages or job incompatibility, it does not benefit the shop in any way. This is why shops are turning more and more to automation to produce parts better. Here is a look at some automation trends.

Hard Automation

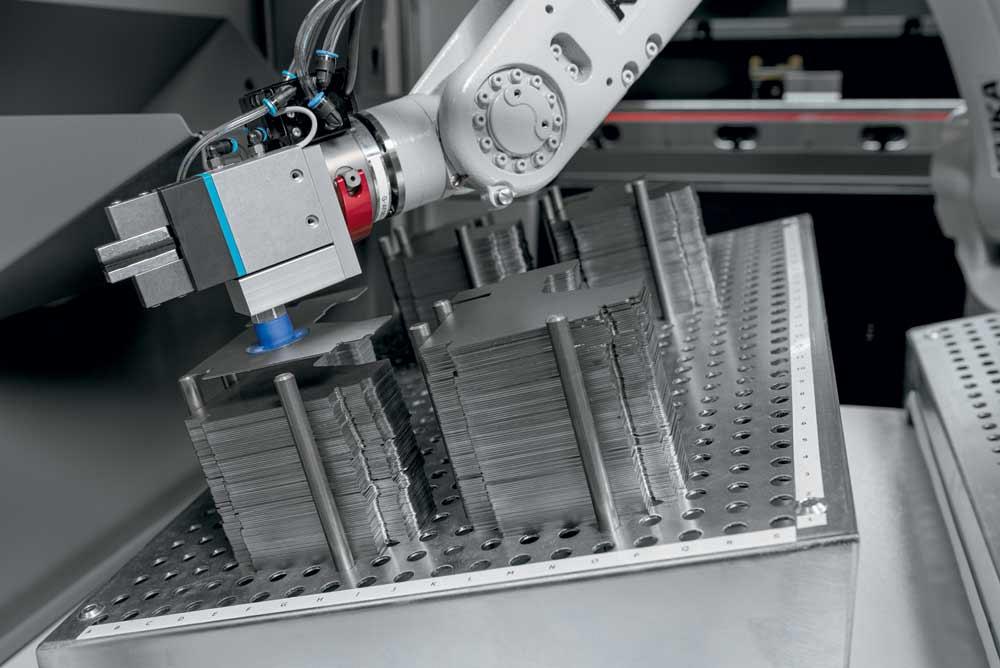

When it comes to press brakes, there are two kinds of automation. Most people think of a standard gated cell housing the brake, positioning table, stackers/destackers, and sorting bins. This traditional method of automation works well for fabricators that are dealing with high-volume, low-mix jobs, where part size varies little.

“Generally, customers turning to automation are bending large quantities,” said Lucas. “They want to produce these large batches more efficiently.”

However, when a shop begins integrating a number of different jobs and part sizes, these cells can be challenging and costly to reconfigure. Some parts are just not robot-friendly or they are either too small or large for a shop’s current robot to handle. If the part doesn’t fit in the gripper, an operator has to change the gripper and it is too heavy, the fabricator needs to buy a new robot. It’s very rigid and expensive to reconfigure.

“It’s ideal for an application where you have enough automation-friendly parts that the operator can just turn this system on to let it run,” said LeTang.However, hard automation is not ideal for shops with many different parts. Needing to reconfigure the cell can be time-consuming and costly. This is why manufacturers have adapted to offer flexible automation as well.Flexible Automation

One of the advantages of a flexible automation system is that it gives a shop the ability to remain agile at all times. Some of the latest systems enable a press brake to be used in both manual and automated operation modes, giving a shop complete flexibility no matter what job is running.

“We have our mobile bending cell,” said LeTang. “It’s a portable unit. When you want to run automation, you plug it into the press brake, and you then have an automated press brake. When you want to run manual, you just unplug it and you are just left with the standard press brake. The automation is completely on wheels and can move.”

The advantage of a portable system like the Mobile Bending Cell is huge machine utilization. Everyone today wants to get the most for their money. According to LeTang, when shops buy a machine, they want to see it running all the time.

A manual machine can sit idle because it doesn’t have an operator. An automated machine sometimes sits idle because the fabricator doesn’t have automation-friendly parts. With this system, the shop can address both issues because of the plug-and-play capability.When automating bending operations, shops have many feature options to choose from to ensurecommon challenges are overcome. Every shop’s unique needs can be met with automated accessories, increasing job flexibility.

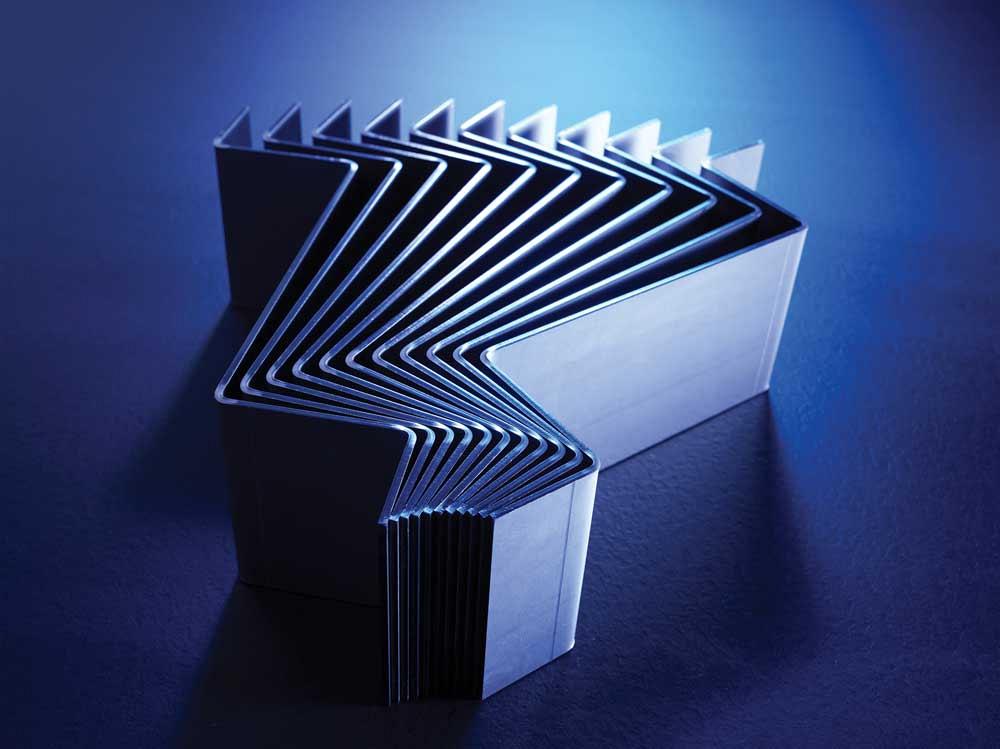

“The addition of automated accessories for the electric press brake is driven by the increasing complexity of parts,” said Lucas. “More complex parts may require different handling techniques or tools, such as a different gripper structure or formation of the robot, various gripper stations, and methods to regrip the parts.”

LeTang echoed this by explaining that operators have the flexibility of using their hands to pick up parts, move them around, and the capability to determine if parts are stuck together. Robots cannot always make every possible turn or adjustment. However, manufacturers are now taking these factors into account and developing optional accessories for their systems to better suit bending operation needs. For example, Bystronic offers a gripper kit that includes numerous different finger and suction cup options.

“We offer lots of different sizes and shapes,” LeTang added. “When the part changes, it can still be robot-friendly. All you have to do is change the gripper.”

Process Control

Incorporating automation in press brake operations not only increases part quality and alleviates bottlenecks, but can help streamline processes.

Manufacturers like SafanDarley, which is distributed in Canada by Westway Machinery, Toronto, have been incorporating robots and automation for the better part of three decades. The company offers a number of automated systems, including the R-Brake flexible bending cell for the E-Brake press brake, which integrates a robot into the press brake, creating a single system.

According to the company, “The robotic arm moves horizontally along a 6-metre-long traverse at the top of the press brake. A feat of bending cell automation is it ensures that the floor in front of the press brake is free for positioning sheet-feed and discharge tables.”

These companies have also noticed trends that have pushed them beyond standard stand-alone systems, pushing automation out into the production process. SafanDarley noted, “Integral automation is not restricted to the bending cell alone; it also applies to other parts of the process such as punching and spot welding, and the entire routing of sheet material around the bending cell.”

Another way manufacturers are streamlining the process is through developing complete offline programming options. Many highlighted the importance of developing a programming solution so that the shop floor can use their time for bending.

Bystronic’s Portable Bending Cell includes features to detect if more than one part is grabbed at a time and a positioning stage to ensure the part is positioned correctly for bending.

“Most manufactured press brakes have high-level software packages that allow for easy programming of the press brake and backgauges,” said JMT, Salt Lake City, Utah. “However, offline programming of robotic automation to manipulate the part blank from inbound presentation to double-blank detection, bend line location, forming operations including regripping, part following to prevent back bending, and formed part palletizing has been cumbersome, impractical, and expensive at best.”

This has been a recognized problem as press brake automation becomes more common, andmanufacturers are developing equipment to deal with this. For example, JMT has partnered with Acieta to develop their proprietary robotics offline programming software.

According to SafanDarley, its offline 3-D programming enables complete and reliable process management. Its design program includes a simulation and control module for using the press brake that can be remote-controlled, from the office, for example, limiting the time during which the machine is at a standstill, thus maximizing productivity.

“LVD is continuing development of complete offline programming for the press brake and robot,” added Lucas. “We’re further evolving CAM technology to speed up the process between the digital part or part program to producing the finished part, improving the flow between the CAM process, the robot software, and the actual bending process.”

LeTang added that the Bystronic Mobile Bending Cell is available with offline programming. Everything is prepared in the office and sent down to the machine so the shop floor isn’t obligated to use their time.

When it comes to maximizing the production process and optimizing machine utilization, fabrication shops are increasingly looking to automation. If a shop generally runs high-volume, low-mix jobs that are robot-friendly, hard automation is an ideal solution and can create lights-out production. For shops that are constantly bending different and complex parts, incorporating flexible automation is a great way to keep the production process agile. No matter what class of automation is needed, offline programming is a clear trend many manufacturers have recognized and are bringing to their customers, making automating bending operations an easy process.

Associate Editor Lindsay Luminoso can be reached at lluminoso@canadianmetalworking.com.

Bystronic, www.bystronic.com

JMT USA, www.jmtusa.com

LVD, www.lvdgroup.com

SafanDarley, www.safandarley.com

About the Author

Lindsay Luminoso

1154 Warden Avenue

Toronto, M1R 0A1 Canada

Lindsay Luminoso, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

CWB Group launches full-cycle assessment and training program

Achieving success with mechanized plasma cutting

3D laser tube cutting system available in 3, 4, or 5 kW

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

Welding system features four advanced MIG/MAG WeldModes

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI