- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

What Keeps You up at Night?

Attracting skilled labour, becoming leaner, managing supply chains all on ownership’s radar

- By Nate Hendley

- July 10, 2017

- Article

- Made In Canada

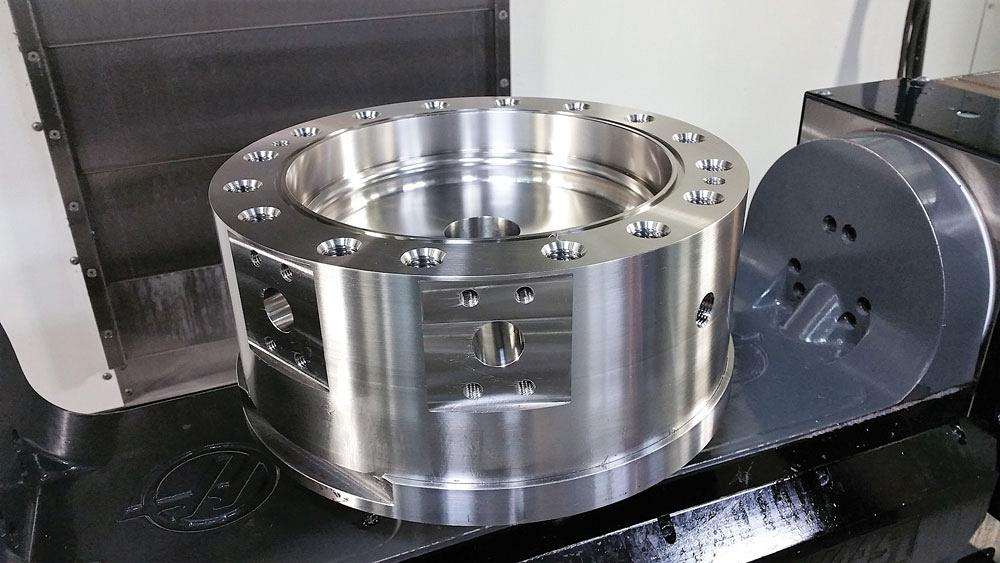

Ellery Manufacturing performs manufacturing and project management for the oil and gas, forestry, mining, marine, and construction sectors. Photo courtesy of Ellery Manufacturing.

What keeps job shop owners up at night? Turns out, it’s quite a number of things.

Skilled labour shortages; regional and national economic woes; and rising utility, labour, and material costs, all set against the backdrop of NAFTA falling apart, are troubling to machine shop owners and managers.

Fortunately, shop owners have plenty of commonsense solutions on how to deal with such issues.

Searching for Skilled Labour

“Our biggest challenge is finding skilled labour. The type of work we do and the scale of the parts we work on require a special combination of technical skills, mechanical logic, and confidence. Finding employees with the right mix of technical and soft skills can be challenging,” said Paul Ellery, vice president of Ellery Manufacturing, Surrey, B.C.

Ellery Manufacturing performs custom CNC and conventional machining, fabrication, and project management for the oil and gas, forestry, mining, marine, and construction sectors.

East coast shop owner Sean MacPhee faces the same issue.

“Our biggest challenge is finding the required skilled labour, especially machinists, to be able to support our customers,” said MacPhee.

MacPhee co-owns Velocity Machining & Welding Inc., based in Dartmouth, N.S., with his cousin, Craig Langille. The two men also co-own Techtronics Machine Works Ltd., based in Musquodoboit Harbour, N.S. While both companies make custom, precision components, Techtronics only does manual and CNC machining, while Velocity offers those services plus 3-D printing, laser engraving, waterjet cutting, welding, and fabrication.

Indeed, even the toughest challenges facing job shop owners have inspired pragmatic solutions. Take the skilled labour shortage, for example.

“The skilled labour shortage is now hampering the continued growth of our companies. We post a job opening, and the overwhelming majority of respondents are not residents of Canada. Whether or not they have the required skills, I have no idea. Our companies are not large enough to be able to support the risk involved with sponsoring foreign workers,” said MacPhee.

"There’s always going to be someone coming up trying to take your customer in the job shop market,” There’s always going to be someone coming up trying to take your customer in the job shop market.” – Ron Wallace

Velocity/Techtronics does, however, sponsor students to attend the Skills Canada National Competition, in the hope that some of these students will be a good fit for either company.

“When it comes to building a skilled workforce, our first priority is to look after our existing team. Ellery Manufacturing invests heavily in our employees, and we put an emphasis on providing our team with a safe working environment and flexibility when it comes to dealing with their lives outside of work. This approach has helped us maintain a strong core of long-term skilled employees,” said Ellery.

“With regards to finding new employees, we’ve found that an ongoing recruiting effort is a must. We used to start looking for candidates only when we had an immediate need on the shop floor. This put us in a position where we sometimes made hiring missteps due to pressure to fill a position quickly. We now recruit year-round, and we make use of digital recruiting tools and social media to reach as many applicants as possible,” Ellery continued.

The company has also learned to be more flexible—to look at potential hires from outside the region, including young people with potential but not a lot of experience, added Ellery.

Focus on Training

Ron Wallace cites work flow and customer retention as his shop’s biggest challenges, in addition to the shortage of skilled labour.

Wallace is the co-owner of Ace Machining in Dartmouth, N.S., along with business partner Andy Race. Ace makes parts and products for transportation, defence, and other sectors. The company has responded to its challenges by focusing on quality control and arranging extended purchase order terms with customers.

According to Wallace, there aren’t enough schools turning out students qualified for shop floor work in Nova Scotia. To deal with the dearth of fresh talent, Ace trains its new hires extensively and recently introduced an employee benefit plan to retain existing workers and attract new ones.

Fighting Rising Costs

If finding new workers can be difficult, rising labour and material costs are also challenges.

“Increasing labour costs and growing material expenses are a fact of life in our industry. You need to fairly compensate your long-term skilled employees, and you also need to be competitive when it comes to attracting new talent. When it comes to material costs, we are at the mercy of the markets. Sometimes growing costs need to be passed on to the customer, but we prefer to focus our attention internally to find savings before increasing pricing. We regularly look at our systems, processes, operations, and vendors to identify areas where more efficiency or a new approach could lead to savings,” said Ellery.

Labour costs are “always an issue. People always want more money. So what do we do to meet that? We’ve had some shop rate increases, and we also try to really focus on operational efficiency [to save costs],” stated Wallace.

Ace Machining cites work flow and customer retention as his shop’s biggest challenges, in addition to the shortage of skilled labour. Photo courtesy of Ace Machining.

According to Wallace, rising material costs are not a huge factor for Ace Machining. In some cases, these costs are simply incorporated into the quote. However, shop size definitely has its benefits in terms of purchasing power.

“As we grow and put out more product, we’ve started buying full sheets instead of partial sheets. We started buying full length instead of bits and pieces that are more expensive. You get a better rate,” said Race.

Manage Inventory Correctly

Careful inventory management has also helped Ace cope with material costs.

“Before we’d buy just enough material to get through whatever it was we were making. Now we have a much broader picture of what we’ll be doing over the course of the next few months. So we know, ‘Oh yeah, get that. We’ll definitely need that,’” continued Race.

“Material costs have been increasing; however, with the type of projects we work on, that has not been an issue yet. There is no lack of competition when it comes to steel and component suppliers. Sometimes a customer will redesign their product when they realize what the cost will be when made from their first choice of material. We regularly work with our customers to help them design products in the most cost-effective manner,” said MacPhee.

Going Global

Like any enterprise, job shops are buffeted by economic trends on a national and regional level.

Ellery Manufacturing, for example, had been doing steady work for the oil and gas sector. The slump in oil prices had a major impact on this aspect of its business. The weak Canadian dollar, meanwhile, makes it more expensive to purchase from U.S. suppliers.

Ellery has worked to diversify, make internal upgrades (facilities, equipment, and technology), and secure industry certification. Ellery is registered with the federal Controlled Goods Program and plans to obtain Occupational Safety Standard of Excellence (OSSE) certification and ISO 9001:2015. And the low dollar can be an advantage in terms of making Ellery more competitive in American markets.

“At the provincial level, the high cost of living in British Columbia, especially in the Greater Vancouver area where we operate, can be a challenge. B.C.’s high taxes, fuel costs, and growing utility costs have a direct impact on our bottom line, and our region’s high housing prices can make it difficult to find employees who may be willing to relocate,” said Ellery.

To cope with B.C.’s high operating costs, the company continuously looks for savings and efficiencies, pays good wages so employees can afford decent housing, and offers support to new employees relocating to the area.

“The type of work we do and the scale of the parts we work on require a special combination of technical skills, mechanical logic, and confidence. Finding employees with the right mix of technical and soft skills can be challenging.” – Paul Ellery

Sometimes it can be advantageous to be based in a region with a static but diverse economy.

Race compares the Maritimes’ economy to a grey day.

“It’s never sunny, it’s never rainy, just somewhere in the middle all the time,” said Race. “It’s not like Ontario. If the auto sector pulls out, everything stops. It’s not like out West, when oil goes down to $40 a barrel, everything stops. We are so diversified here in Atlantic Canada with our industry that it’s pretty hard to shut us down. We’re heavily resource [based], but we’re also heavily research and development and manufacturing [based].”

Other challenges for job shops include political issues and utility costs.

“Many of the customers we work for supply services to companies operating in the United States, and Ellery Manufacturing also works directly for several American customers. If the U.S were to leave NAFTA, this would certainly have a negative impact on our ability to generate new opportunities south of the border,” said Ellery.

For his part, MacPhee noted, “Rising electrical and water rates are a burden, but not overwhelming. The possibility of the U.S. leaving NAFTA could prove to be an issue for some of our customers, so it could very well affect our businesses, but that remains to be seen.”

Being competitive requires being up-to-date on technology and equipment. Ellery Manufacturing recently implemented a new enterprise resource planning (ERP) software system and IT hardware and network upgrades. The company also added an automated vending supply system on the shop floor.

“We strive to stay on top of technology and installed our latest vertical machining centre and a set of plate rolls six months ago. Typically, our customers drive change. We acquire new equipment and processes when they have a need for services that we may not currently provide,” said MacPhee.

Ace Machining recently purchased a new Mazak CNC machine, as well as a new brake, ironworker, and CMS waterjet cutter. Ace also increased its welding staff to five personnel and moved into a new, 14,500-sq.-ft. facility last year, which features an overhead crane.

In addition to new equipment, finding new markets is another way for job shops to overcome business challenges. As mentioned, Ellery Manufacturing is seeking new clients outside its traditional environs and has secured jobs in the renewable energy sector.

“Typically, our customers drive change. We acquire new equipment and processes when they have a need for services that we may not currently provide.” – Sean MacPhee

Embracing management or organizational methodologies, from lean to Six Sigma, kaizen, and 5S, is another tried-and-true method of strengthening a company.

Ace Machining recently underwent operational efficiency training with an engineer from the Business Development Bank of Canada (BDC). This training, which incorporates some lean concepts, aims to boost profits and cut costs by identifying and isolating waste, implementing best practices, re-engineering processes, and reducing inventory and purchasing costs.

“I personally was apprehensive, but I think it’s probably one of the best things we’ve invested in. Now we have a meeting every Tuesday. All the staff get together and we talk about improvement ideas,” said Wallace.

Regardless of what kind of solutions job shop owners utilize to meet their challenges, the end goal is always the same.

“We’re trying to make sure we’re putting out a good product at the end of day and save the customer money. There’s always going to be someone coming up trying to take your customer in the job shop market,” said Wallace.

Contributing writer Nate Hendley can be reached at nhendley@sympatico.ca.

Ace Machining, 902-463-6347, www.acemachining.ca

Ellery Manufacturing, 604-882-9122, www.ellerymfg.com

Techtronics Machine Works Ltd., 902-889-2418, www.tmwltd.ca

Velocity Machining & Welding Inc., 902-434-4428, www.velocitymachining.ca

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI