Professor and Program Coordinator of the Mechanical Engineering Program

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Ontario’s Centennial College Transforms Students into Skilled Workers

Mechanical engineering programs use hands-on product development approach to add a measure of excellence

- By Lucian Toma, PhD

- February 15, 2017

- Article

- Measurement

Centennial College, the oldest publicly funded college in Ontario, is committed to being an active contributor to the community and its manufacturers. Some of the institution’s goals are bringing new, essential skills to a global community; driving innovation; and redefining the relationship between education, experience, and employment. The college’s continual, dynamic program changes ensure that it is aligned with its commitments and offers skilled, knowledgeable graduates to our society.

Centennial College offers three mechanical engineering programs: Mechanical Engineering Technician Design, Mechanical Engineering Technology Design, and Mechanical Engineering Technology Industrial. Each program is also aligned with the college’s commitments and, consequently, undergoes continuous improvement to ensure that our graduates have the necessary, relevant skills.

Any discipline in a mechanical engineering program should be improved and adapted to reflect the technologies currently in use in the industry. Teaching students about new materials, new manufacturing processes, and the latest computer software applications (to name just a few of our course topics) is a must. However, we are aware that just offering a collection of courses will not help our students become competent employees. They need to know how the course topics relate to each other, and they need to understand why they learn certain disciplines.

To help students understand how mechanical engineering fits into manufacturing, we teach product development, including all the activities related to the various stages of a product life cycle: concept, design, analysis, prototyping, testing, manufacturing, and quality assurance, along with how resources and the stakeholders are involved. The mechanical engineering programs take students on product development journeys so they obtain the necessary skills to perform a variety of roles within the process.

Through our experiential learning concept, the students become involved in product development during their first semester. They are taught shop activities like machining operations, welding, soldering, assembling, checking and measuring, testing, and material handling. They are also exposed to how work orders and inventory maintenance are involved to provide a real working environment. We teach skills to help them face and solve shop floor problems.

EXAMINING PRODUCT LIFE CYCLE

The product life cycle projects start with a product concept that relates to a customer need. Through their capstone projects, the students are tasked with aligning the concept of a new product to the needs of the consumer market by adding specific features that will enhance product sales.

Geometric dimensioning and tolerancing (GD&T) principles and computer-aided design tools like SolidWorks®, Autodesk® Inventor®, and AutoCAD® are taught, and students use them extensively to bring their concepts to the design phase by generating 3-D models and GD&T drawings. But we also make the students aware of the impact of their designs on the production process and the importance of specifying the correct tolerance to the functionality, the assembly, and the manufacturing of the product. Then we work with them to understand the impact of their designs on the business.

Product model analysis teaches the students about the tools they must use prior to releasing the design for manufacturing. Computer-aided engineering simulation tools like finite element analysis using ANSYS® software and dynamic simulation using Autodesk Inventor are used by the students to validate and optimize their design before prototyping. In some cases, real parts are analyzed and reverse-engineered. Material savings and product reliability are analyzed from a cost perspective.In addition to basic machining, students become familiar with other manufacturing processes through hands-on training, including CNC, EDM, and rapid prototyping as they produce prototype parts.

VALIDATING THEIR WORK

Product validation is also emphasized. The product or process quality assurance principles are taught through courses that teach skills from basic quality control activities to advanced quality concepts. The business impact of good or poor quality is revealed to our students. Instructors with industry experience in quality assurance share real case studies about parts that had challenges and how they were resolved.

GD&T is an important vector in the quality equation. How to generate a drawing, how to read a GD&T drawing, and how to create a measuring plan are emphasized.

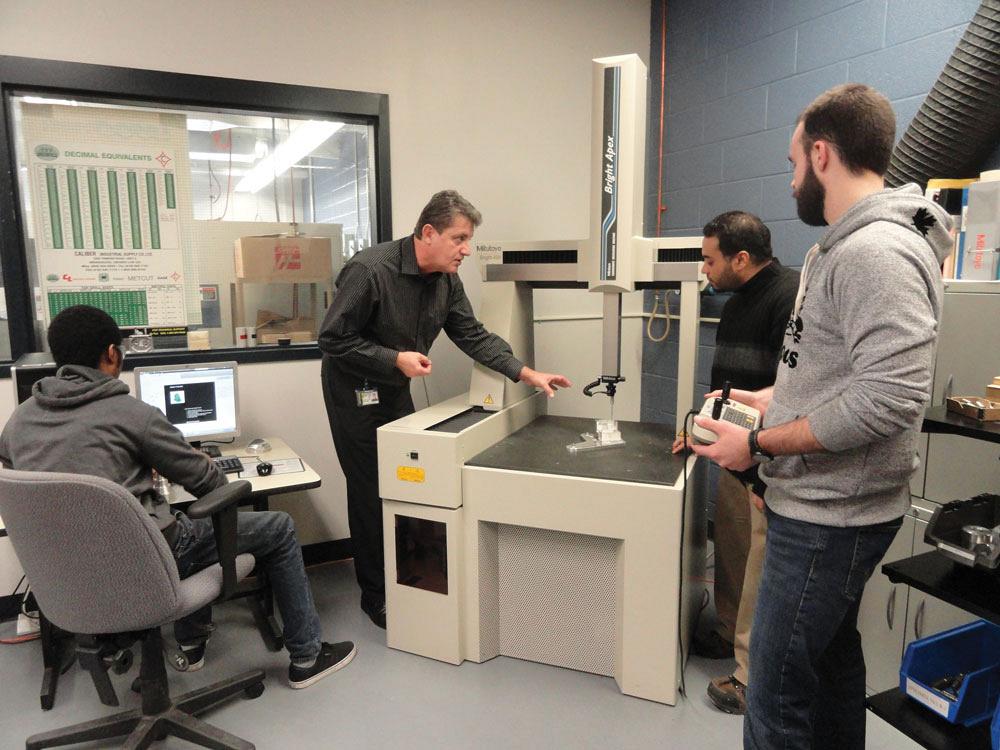

The principles of quality control are taught by associating the GD&T requirements to an appropriate measuring plan. The students become familiar with measuring tools from basic vernier calipers and micrometers to the more advanced measurement technologies like coordinate measuring machines.

Teaching when and why to use a specific measuring tool is one of the focuses of this training. The students are introduced to quality control labs where they can compare the results using different measurement tools, understand how the measurement process can influence the accuracy of a product quality report, and how the report can influence the business. The students learn why there is a need for accurate measurements, but they are also made aware of the quality control cost. An example is how embedding a CMM that will give the most accurate measuring results in a production line with a volume of hundreds of parts per day can save a company money.

Students are gradually introduced to different quality control techniques. First, they learn how to manually measure single parts using basic measurement tools. Second, they use MCOSMOS® software from Mitutoyo to learn how to measure single parts using a CMM. They discover the advantages and the problems they may have using these methods and others to provide measurement data when dealing with mass production.

By performing sample measurements and using statistics principles, the students learn how to apply measurement results to an entire lot of parts and use the results to evaluate if the lot meets specifications. They learn how to use the CMM in a repetitive mode and speed up the measurement process of a sample batch.

LEARNING MEASUREMENT TECHNIQUES

The last stage of the product development cycle training teaches CMM programming. Using a CAD model, GD&T drawings, and offline licences of MCOSMOS, students generate programs for the CMM to perform entire sequences of measurements and automatically generate measurement reports. The students evaluate different measurement scenarios and perform offline measurement simulations to avoid collisions that could damage a probe and to improve the measurement process. The optimized scenario is adopted and tested on a real part using the CMM.

To better teach the product life cycle principles, we have the students adopt a collaborative approach to their projects toward the end of the programs.

Teamwork is the focus. Students are assigned different tasks to accomplish with the collaboration and support of other team members. We create an environment similar to what the students will experience as part of a team at a manufacturing facility.

Project management principles are applied to each team plan. Working together, the teams track the time and the resources required for different tasks and learn to identify problem areas and apply corrective actions. Important objectives of our product development program are familiarizing students with the impact of the supply chain and situating the engineering education in a business context.

MOVING FORWARD

Each student-designed product is analyzed and verified through engineering calculations and computer-aided engineering. Prototypes are produced using different manufacturing processes and validated through various tests and measurements.

Finished products become feeders for case studies in other courses. Parts or assemblies from one class are used for students in other classes to develop statistics, calculate material strengths, and for FEA studies. The products are also used for jig and fixture projects used for CMM part validation.

At Centennial we strongly believe that our students can be successful in their careers only if they learn at the beginning what an industrial environment means, what a product life cycle is, what role they can play, and how important their jobs will be. We have the certitude that by continually adapting our mechanical programs to this purpose, our graduates will acquire the skills that will serve them well as individuals, prepare them for their manufacturing careers, and provide skilled workers for our community.

Lucian Toma, PhD, is a professor and program coordinator of the mechanical engineering program at Centennial College, 416-289-5000, ext. 2982, www.centennialcollege.ca.

About the Author

Lucian Toma, PhD

941 Progress Avenue

Toronto, ON M1G 3T8 Canada

(416) 289-5000

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI