Product Manager

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Safety improves with automated barrier doors

Training to learn the root cause of safety incidents leads to the use of new technology

- By John Ritter

- May 28, 2019

- Article

- Metalworking

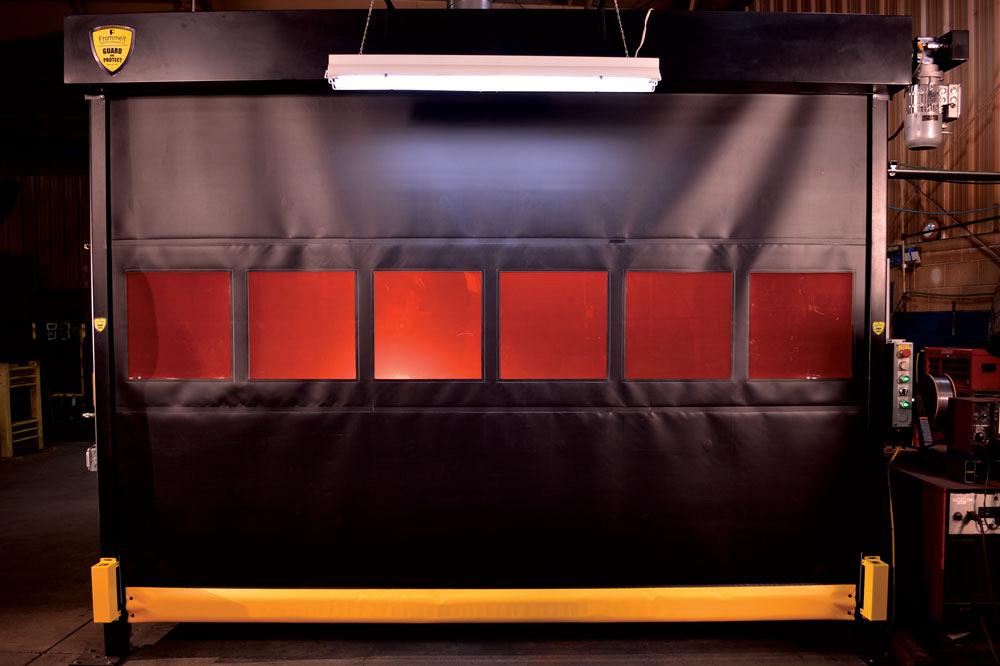

Automated barrier doors protect workers from the hazards of the machining process, including flying debris, fume, and automation systems.

Working more efficiently with new equipment doesn’t mean safety needs to be sacrificed. In fact, more and more facility managers are learning that the latest technology actually improves safety along with efficiency.

Using this technology properly, however, requires understanding why and it needs to be used. Training in this area is paramount.

Machine guarding is one area in which safety and efficiency go hand in hand. Workers trying to get around safety measures in an attempt to increase throughput is why machine guarding is always in the top 10 most frequently cited OSHA standards violated every year in the U.S.

It’s also one of the most confounding aspects of manufacturing plants with risks in the interaction between automated processes and employees at points of operation. These risks include sparks, smoke, flying debris, robots, and even the machines themselves.

It can be a deadly interaction.

According to the Association of Workers’ Compensation Boards of Canada, 160 of 951 Canadian worker deaths in 2017 were in the manufacturing industry.

This danger is the reason that employees need to be trained in the proper use of machine guarding.

Understand risk

Before looking for answers, facility managers should begin by performing a thorough risk assessment.

A risk assessment must be performed any time a new machine or process is added to an operation. RIA R15.06 and CSA Z1002-12 (R17) both require risk assessments to ensure the safety of workers and to make sure they are properly trained in the equipment’s safety features.

When performing a risk assessment, the facility manager will usually find that point-of-operation guarding is the most involved aspect.

Placing a perimeter guard around the entire process minimizes risk, but this guarding system just isn’t practical in reality. Most situations require a machine operator to interact with the process by loading or unloading materials and run the machine.

It’s at the point of operation where things get complicated.

Many facility managers reference CSA Z432-16, Safeguarding of Machinery, and a number of details in it must be considered, including the layout or design of the process, the limits of the system, and the proper identification of all associated hazards. From there, methods for hazard elimination and risk reduction must be established.

Using the distance formula as identified in safety guidelines often helps determine the best machine guarding device. Per this formula, the safeguarding product has a prescribed location based on a number of factors, including secondary hazards that might harm a machine operator, such as flying debris.

Operators need to be taught about these dangers and how each type of guarding device keeps them safe.

Presence-sensing devices

Light curtains, laser scanners, and other presence-sensing devices are commonly used and widely accepted methods of machine guarding in manufacturing facilities from Tier 1 automotive to small machine shops. Automated processes cease once the safety device’s infrared beam is tripped.

In many instances, these devices provide acceptable safety. However, they’re not always the best choice in all applications, which a risk assessment will reveal.

For example, a light curtain may be a good choice in many applications, because it can limit exposure to the hazard and reduce risk. But a fast-acting automated barrier door or roll-up curtain sometimes may be the better choice because it can eliminate exposure to both the dangerous movement of the machine and secondary hazards produced by the process, potentially eliminating risk and the severity of exposure.

Coupled with safety interlocks (up to PLe per EN ISO 13849-1 when integrated properly), automated barrier doors and roll-up curtains offer an increased level of protection for point-of-operation guarding. Not only do they restrict access to the process, they also contain the secondary hazards by placing a barrier between machine operators and machine movement.

Automated barrier door benefits

Because of the nature of a properly interlocked automated barrier door, certain aspects of OSHA’s safety distance formula become moot because there is no depth penetration factor. This allows the safeguard to be placed much closer to the hazardous area.

This resulting smaller safety zone reduces the manufacturing cell’s footprint. This space savings is a benefit in most facilities and it means workers can actually stand closer to the automated operation than with light scanners. The smaller safety zone might also improve ergonomics for the machine operator by limiting required motion and help increase productivity.

The elimination of accidental entry into the cell is another benefit of interlocked automated barrier doors. Because they provide safeguarding that can be seen (unlike invisible infrared beams of presence-sensing devices), the opportunity for accidental work stoppage is greatly reduced. The physical separation they provide is a clear visual indicator that the machine operator needs to be on task.

Because of this, this type of barrier requires less training.

Working safely and efficiently

Limiting risk for workers is a major component in running a successful operation. Regardless of the safety device that is ultimately selected for machine guarding, facility managers need to remember to start with a proper risk assessment.

When it comes to metalworking facilities, physical barriers can offer additional protection from secondary hazards, essentially shrink a workcell’s footprint, and generally improve productivity.

John Ritter is product manager for Rite-Hite, 8900 N. Arbon Dr., Milwaukee, Wis. 53223, 888-841-4283, www.ritehite.com.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI