- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Measuring is easy with Zoller

Interview with Christian Pfau, Head of Research & Development at ZOLLER.

- By Canadian Metalworking

- October 6, 2014

One thing is certain, tool measuring and inspection machines need to be precise. What is often less clear, however, is how the machines work. This is why they are usually operated by specialists in special measuring rooms separated from their colleagues in production.

When you use ZOLLER machines, things look different. The machines can not only be positioned in the middle of the shop floor, they can also be operated by skilled workers from the workshop.

An example: The employee of a metal cutting sub-contractor was not overly delighted when he visited the ZOLLER exhibition stand with his boss and was asked to test the »genius« machine with »elephant« technology himself. Initial panic was followed by a pleasant surprise. It was really as easy as promised. Instead of disgrace, his boss was impressed.

Christian Pfau, Head of Research & Development at ZOLLER, has an abundant collection of stories like this. It is common, also in the field of tool measuring machines, to promise simple operation, with the flaws becoming evident only once the machine has been purchased. This is why ZOLLER recommends visiting the machine manufacturers with your own tools to have these measured without preparation in advance.

Test first, then buy

"If a person visits the ZOLLER exhibition stand, he can either program and measure the tools he brought along himself or with the aid of a ZOLLER sales person (not a programmer) in 99.9% of times. This type of spontaneous test is virtually impossible with most competitors," explains Pfau. "To do this you either need to be a programmer yourself or have one on the stand. 'No problem' is our motto."

Focusing on benefits for the customer

"Originally, we come from the field of tool presetting and measuring machines, in other words, from a production background. Not the sort of place where professors of engineering or software specialists usually work. Here you need machines which are easy to operate and enduring. Otherwise it is pointless putting a measuring machine into a production environment... Good technology simply has to work, otherwise it won't be used," Pfau explained the reasons why ZOLLER devotes so much expenditure, manpower, hard work and attention to detail on the development of the products. "We always think of the people who have to work on our machines, often for years. We focus on long-term relationships and satisfied customers. This is why we develop systems with a high automation content, with a clear operating structure and which can communicate with other systems via interfaces, so that operating errors, and thus downtimes, can be avoided.

In addition, we have an excellent international service team which helps customers locally in case of questions."

Stable measuring results worldwide—at the push of a button

One needs to think further than just the measuring machines, says Pfau. "For example, [it was important to think] about the help texts in the software as well the instructions for use in the customer's language and application videos. On automatic search functions, monitoring of tool clamping, tolerances, transmitted light, computer temperatures as well as fault diagnostics and remote maintenance—there are thousands of things that need to be considered."

For example, to ensure consistency of the measured results, the measuring task and evaluation range need to be defined automatically and the tools always measured in the same way. "This is like a cooking recipe, the result will only taste alike if the ingredients and amounts are correct," explains Pfau. "The current »pilot 3.0« control software includes an export function so that the target dimensions, measuring and image processing parameters defined in the ZOLLER measuring system can be outputted in XML format. These are small files containing all relevant data for the tool, which can be transferred then via USB stick or e-mail. These data can be imported everywhere in the world to measure tools at the push of a button in the same way as at source. The user does not have to create the data again and benefits from the know-how of the tool manufacturer."

Simple machines spell more profit in the end

Another advantage of simple inspection and measuring machines is operator independence. Mr Pfau quotes tool control as an example, "Let us take a closer look at the rounding of cutting edges. If conturographs are used for inspection and these are operated incorrectly, then the diamond tip is gone and 1,000 USD are down the drain". And that is just one of the parameters to be measured. Using different measuring machines can lead to further complications. "Often different historically developed measuring systems are in use which were purchased over a period of decades," says Pfau, "and every system is operated differently and requires immense training efforts. In addition, these machines are no longer state-of-the-art in technical terms and are usually not linked to each other, in other words there is no common data base, which makes documentation of the results a major task."

"Instead of hiring many employees with many systems in inspection, tools can be measured safer and more accurately at the push of a button with automated solutions, as well as measuring all parameters at once. The results do not depend on individuals, are documented seamlessly, expensive mistakes are avoided, and the quality and service life of the tools is improved," summarizes Pfau. The advantages of easy-to-operate measuring solutions are obvious: satisfied users, more efficient production lines and greater profits for the businesses.

Example 1:

Tool measurement with »elephant« technology

Fully automated measuring at the push of a button: standard tools can be measured with »elephant« technology by ZOLLER without data entry and previous knowledge.

Measures tools without prior data entry fast, contact-free and with a choice of up to 52 parameters. No training, no previous knowledge required, things can't be much simpler.

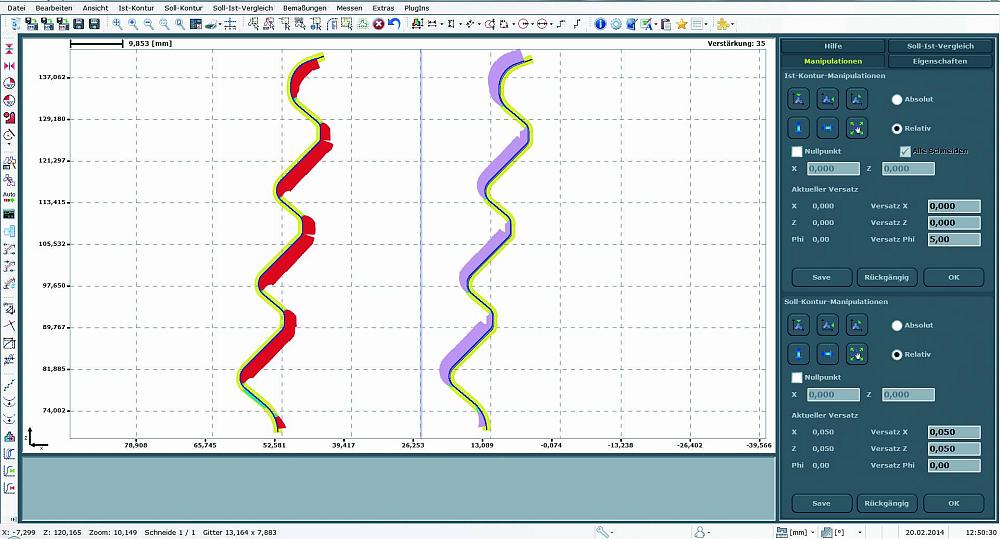

Example 2: Checking profiles of form tools with »coCon«service

Scanning of contours, target-actual comparison and automatic output of the DXF target contour for grinding and eroding machines.

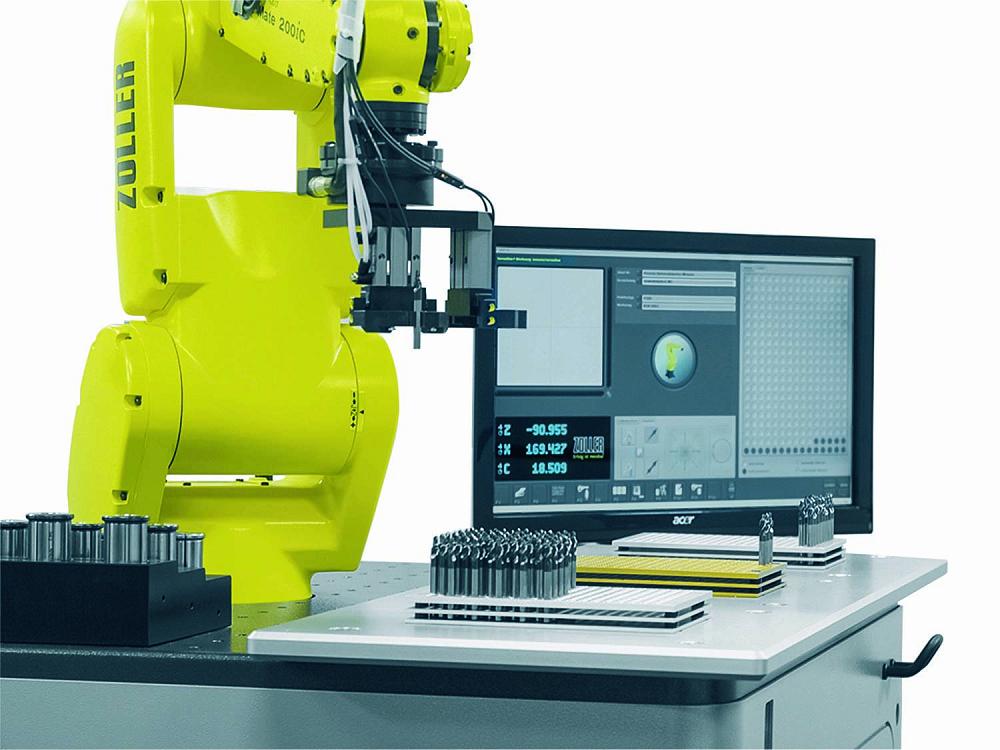

Example 3: »roboSet« as simple, smart automation solution

Runs smoothly 24/7 – just by clicking the Start button of the ZOLLER »pilot« image processing system.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada