Product Manager, Welding

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

The perfect robot programming match

Finding the ideal robot programming method to match your task

- By Josh Leath

- April 7, 2022

- Article

- Automation and Software

Easy-to-program robots with innovative peripherals are making it possible for flexible production environments to handle diverse demands. From better worker use and enhanced equipment effectiveness to extremely consistent operations, robots are providing transformative benefits for greater ROI.

Programming is key to these benefits. For decades, the standard robotic teach pendant has been the programming doorway for adding parts or making modifications to new jobs. While it has evolved with greater ergonomics and user features, this method takes a robot offline and prohibits production while programming for new parts. To broaden robot application integration and even reduce the robot programming learning curve, new programming methods continue to arise.

Offline Programming

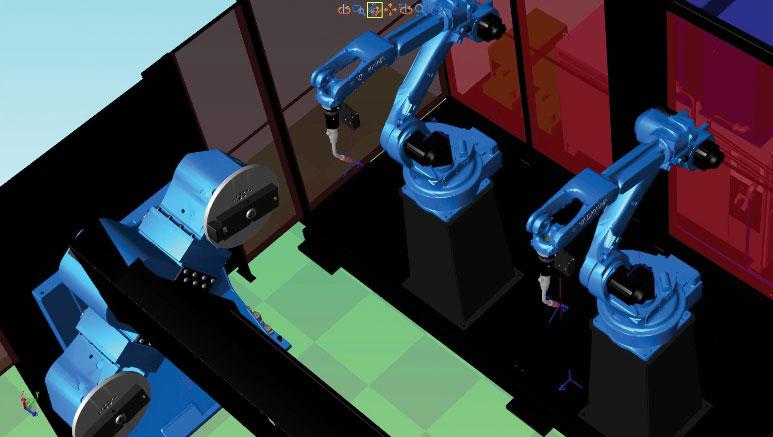

New software and intuitive applications have made the use of offline programming (OLP) possible for a variety of robots. Using a 3D representation of a robotic workcell or production line that visually demonstrates how a robot moves along a programmed path, OLP gives users the ability to design, test, and adjust a robot program from a personal computer. Similar to CAD software, this PC-based virtual environment allows programmers to perfect a job before it is invested in and implemented.

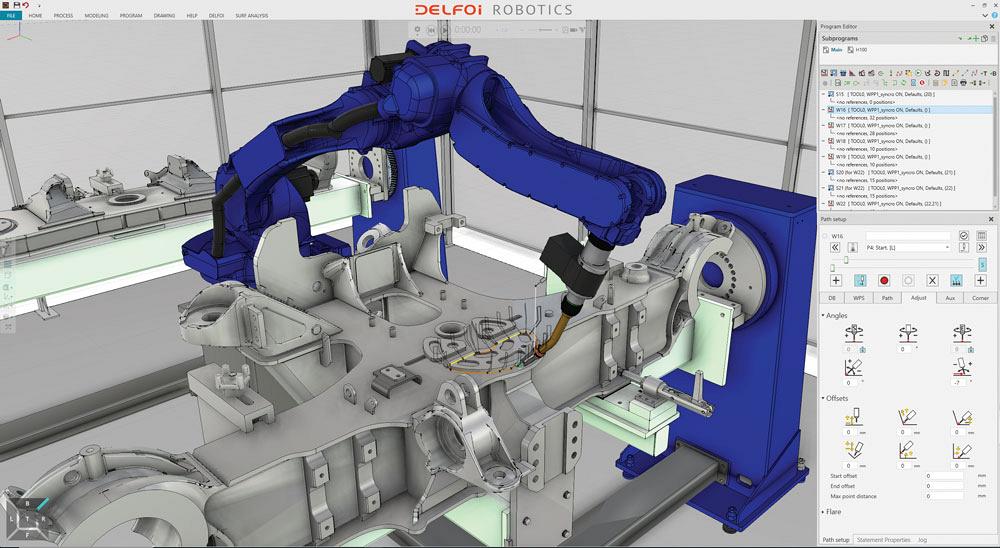

Offline programming suites, especially for tasks involving robotic weld systems, offer a variety of specialty tools to accommodate various application needs. For example, Delfoi SPOT and Delfoi ARC provide tools to facilitate highly accurate weld production, and suites such as Hypertherm’s Robotmaster offer plug-ins for additive manufacturing. These plug-ins allow robot users to input a model, convert it with a 3D slicer, and then generate a path to build up the part.

Simpler OLP packages, such as Yaskawa’s MotoSim, mimic the robot OEM controls and can provide an interface for reach studies or cycle time measurement before implementation. Certain OLP packages enable animation-based robot programming, allowing robot users to create and program fluid robot motion. Often referred to as robotic choreography, tools like this allow programmers to save time when creating complex production workflows.

For very large operations in which the same program is deployed into multiple workcells, OLP helps ensure consistency. This goes for workcells with multiple robots and other external axes, such as positioners or floor tracks, as well. Similarly, predictions for accurate cycle time can also be made via OLP with built-in trajectory and path optimization tools that allow programmers to alter jobs as needed to improve production rates.

Manufacturers looking to verify the use of the proper robot and tooling before the program is used on the shop floor should consider OLP to avoid costly retrofitting. The ability to tinker with the workcell layout and tooling design to see if there should be any modifications is extremely cost effective. All in all, offline programming reduces robot downtime and maximizes production uptime, addressing repetitive low-volume production demands while fostering productivity gains.

Keep in mind, parts can deviate from a drawing or CAD model, which means that using additional welding technologies in conjunction with offline programming can be helpful. For instance, sensor technology can provide greater control of welding parameters and robotic motion, along with improving fault detection and correction. Technologies can be mixed and matched (where use is not redundant) for a variety of robots and workcells. Tools for high-speed seam finding help locate weld joints, and peripherals for weld joint tracking help monitor the position of the weld in real time once the arc has been established.

Precision Hand-guided Teaching

One of the most popular methods of simplified programming for fast robot implementation is hand-guided teaching (or lead to teach). Users physically grab and guide a robot by the t-flange, simplifying the concept of learning a coordinate system and fostering a quick learning curve for even novice robot programmers. Note that an industrial robot with power and force limiting—usually labeled as a collaborative robot—is required to perform this style of programming, and a teach pendant is still used with most robot brands to record points.

For welding applications, programmers who already know how to position and travel a weld torch can simply recreate the same movement with a robotic torch. Again, this is especially helpful in high-mix/low-volume environments where frequent changeovers occur. Remember, for some applications, hand-guiding may make it difficult to adjust tool axes or individual robot axes for access into parts or in tight spaces. In these cases, hand-guiding is often complemented by traditional programming methods.

Offline programming suites, especially for tasks involving robotic weld systems, offer a variety of specialty tools to accommodate various application needs. For example, Delfoi SPOT and Delfoi ARC (shown in use here) provide tools to facilitate highly accurate weld production. Delfoi

Software Applications

Intuitive tablet-style teach pendants and open programming environments continue to enable the trend toward no-code programming. Thanks to improved graphical user interfaces with touchscreen capability and simple menu structures, robot users are gaining greater confidence, taking comfort in familiar device offerings like icon-driven programming. To facilitate no-code shop transformations, robot suppliers and third-party developers are promoting flexible development platforms and specialty application modules to program an app or robotic system without writing a single line of code.

For welding, pendant applications such as Yaskawa’s Universal Weldcom Interface are permeating historic programming barriers to help users gain control of any weld process or parameter, including voltage, amperage, and wire feed speed. The UWI provides pendant access to advanced waveforms, as well as processes developed by the power supply manufacturer. These processes are matched for welding certain metals that have specific shielding gas requirements or proprietary filler metals. Additional features include touch sensing, which lets the user find a workpiece using voltage through the wire, and dual pulse, which can call up two waveforms and alternate between them to provide TIG-like aesthetics.

Making industrial robots more accessible to everyone, companies like Wandelbots take hands-on and icon-driven programming to the next level to generate safe and compliant, yet easy, programming. A hand-held “wand” that is used to trace program points for command of the robot movement can reduce programming time from hours to mere minutes. Sensors on the wand triangulate with three emitters placed around the work area to capture the needed data. Capable of marking single points or complex paths where tool velocity and orientation is marked, this AI-based application also enables easy path adjustments, visual skill editing, full stack applications, and fast editing.

AI and Vision-based Applications

Manufacturers seeking to build company resilience and accommodate diverse demands are turning to robotic automation mixed with artificial intelligence and machine learning to manage process complexity. From automating or augmenting repetitive manual tasks and analytic processes to classifying complex data, detecting anomalies, and predicting the probability of future events, AI is being applied in practical ways.

While AI-based and machine learning applications are extremely complex to create and maintain, they can provide benefits to robot users.

For instance, Mujin systems combine AI and autonomous motion planning to optimize bin picking, insertion, piece picking, and palletizing.

For welding, Path Robotics has a proprietary version of AI software that uses advanced patented technology to determine part shape and weld seam locations and provide quality analysis of weld performance. Usually using direct robot interfacing, these systems offer pre-selected weld settings that allow one-off parts for high-mix applications.

ROS-Industrial (ROS-I) is frequently used to provide adaptive functionality needed to make modifications to traditional industrial robot applications. This compilation of feature-rich development tools focused on the capabilities of the Robot Operating System (ROS)—a free, open-source repository supported by Open Robotics at ros.org—is seen by some as the glue that holds advanced technology together. For example, many complex tasks, that use 2D and 3D image processing and force control to drive the robot path in real time use ROS-I. A growing number of robot suppliers, including Yaskawa, use this technology on their robots for expanded functionality, especially for manipulating, navigating, and sensing.

Similarly, unified PLC programming environments are also facilitating complex applications for motion control. Yaskawa’s MLX300 software option, used for secondary packaging, provides a standard PLC programming environment that allows users to gain complete control over every networked component (robots, servos, variable frequency drives) without knowing a separate robotic programming language.

Rapid Automation Growth

While the application typically determines the programming that works best, it is always helpful to understand the options available. As manufacturers adopt more automation, including the use of robotic arms, the need for intuitive programming methods will gain traction, and new methods, including the use of animation to help choreograph robot movement, will arise. Overall, the accessibility to automation will continue to grow rapidly thanks to these programming technologies.

Josh Leath is product manager, welding at Yaskawa America Inc. – Motoman Robotics Division, 2121 Norman Drive S., Waukegan, Ill. 60085, 800-927-5292, www.motoman.com.

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

FMA Annual Meeting: Ingenuity still key with tech innovations

Automotive industry gets back on track

The 22nd annual Great Designs in Steel symposium returns May 22

Torch made for welding thin, conductive sheet metal

Compact swing chamber shot blast machine features robotic workpiece handling

- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada

DiPaolo Machine Tools Open House 2024

- June 4 - 5, 2024

- Mississauga, ON Canada