- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Control the top 3 areas of band saw frustrations

Reduce machine downtime, blade failure, and operator error

- By Sue Roberts

- February 17, 2017

- Article

- Fabricating

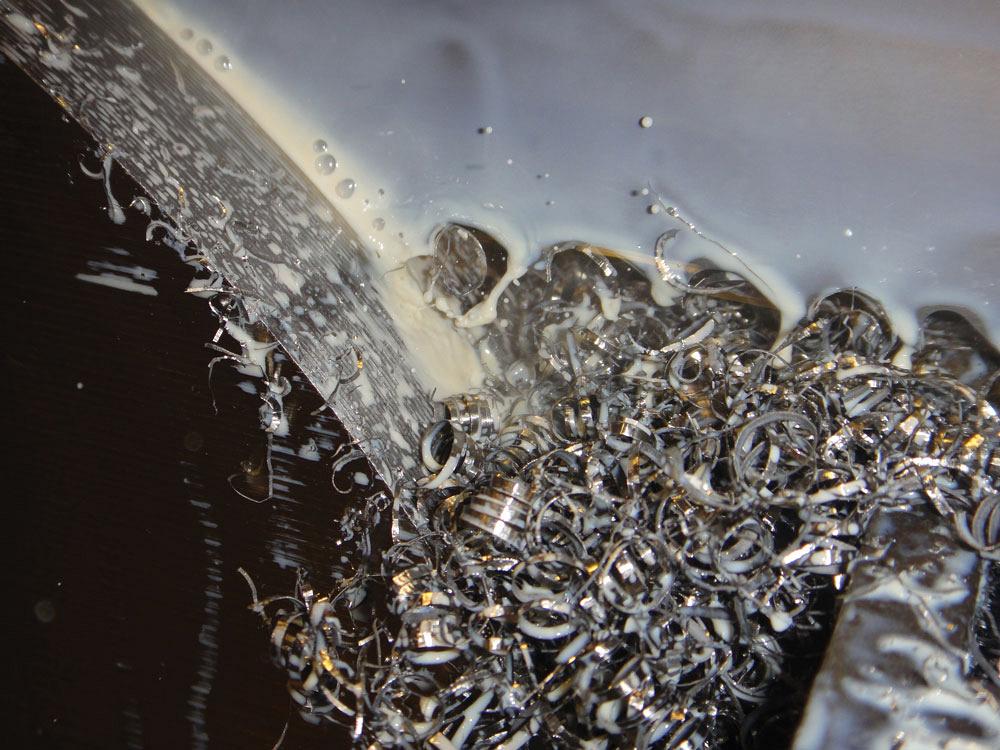

A high-quality band saw coolant should be used to cool, lubricate, and remove chips. Photo courtesy of Simonds International.

A common production floor sight is a band saw feeding material to a series of CNC machines that contribute a substantial amount to the shop’s profits. When the saw goes down, downstream productivity and the department’s billable hours can grind to a halt -- not good for work flow, the customers’ deadlines, or the company’s bottom line.

Giving the saw and the blade the care and respect too often reserved for the more complex equipment can reduce the risk of downstream downtime caused by a lack of cut material.

Matthew Lacroix, director of marketing for LENOX®, said that fabricators have three main areas of concern regarding their band saw processes. “The top frustrations that we repeatedly hear from fabricators are machine downtime, blade failure, and operator error. In each case there are steps they can take within their own organizations to manage the problems.”Here are some recommendations to help a fabrication shop avoid frustration in their band saw department.

Reduce Machine Downtime: Clean Away Chips, Then Clean Again

Saws create chips, dust, and dirt. It can’t be avoided, only managed. Saw experts agree that machines should be flushed and cleaned regularly.Chip buildup can wreak havoc in several areas of a band saw. Jay K. Gordon, The L.S. Starrett Company’s North American sales manager for saws and hand tools, said, “Saw cleanliness is one of the most overlooked components in saw management. Chip buildup in the guides, bearings, cylinders, and shuttle ways can do extensive damage.

“Like automobiles, band saws need their oil changed. This includes the hydraulic and transmission oils as well as--at minimum--an annual flush and recharge of the coolant system. Checking all the fluids on a daily basis and monitoring the coolant condition and mix ratio can allow small issues to be resolved before they become large issues.”

Operators need to do the best they can to keep the machine surface clean so coolant has a clear path to the cutting zone without collecting chips along the way. Lenny Borowski, sawing specialist at DoALL, said, “I’ve seen many machines with chip buildup so thick that the coolant can’t flow. Over the years the chips can actually corrode to the machine and seem to be part of the saw. They can block or redirect the coolant so it can’t do its job of washing, cooling, and lubricating. It’s almost like cutting dry. And whether you are using a mist or the more traditional flood, the coolant should be kept clean.”

A check list from Dirk Herzog, North American sales manager for Simonds International, provides inspection and cleaning actions that can help eliminate unanticipated saw downtime when performed regularly:

- Clean the chips off the band wheels when changing the saw blade.

- Wipe or use air to remove excess chips from the saw guides.

- Wipe down or use air to remove metal chips from the vise clamps and the surrounding areas.

- Inspect the chip brush and adjust it so it lightly touches the blade teeth.

- Check coolant nozzles to make sure coolant is flowing freely.

Regular checkups from the equipment or saw manufacturer can help troubleshoot potential problems. Lacroix said, “Take advantage of the information available on many of the websites and of the inspection services available to avoid unpredicted downtime. Some companies provide these services at no cost.”

Reduce Blade Failure: Manage the Details

Many small issues, several that can be controlled, can cause a blade to fail.

Many types of blades are available. Some are for general- purpose cutting and some are for specific materials. Select the correct type of blade -- carbon, bimetal, or carbide-tipped -- for the material as well as the proper tooth pitch to get the most production and longest blade life. This is an area where guidance is readily available from blade manufacturer representatives. There is no one-size-fits-all.

As important as blade selection is, there are times when it either isn’t practical to stock all the ideal blades for various jobs or a company needs a quick fix. Some flexibility can be gained without damaging the blade or the cut quality if speeds and feeds are adjusted.

“If a 2-3 pitch is called for to cut a 6-in. round, a 3-4 might work as a secondary suggestion, but it will require some machine adjustments to be sure the right number of teeth are engaged in the cutting process. As a rule of thumb, a minimum of three and a maximum of 25 teeth should be in the workpiece at all times,” said Borowski. “If you don’t adjust your feed and speeds to accommodate the fact that you are not using the recommended pitch, you risk stripping teeth or breaking the blade.”

Borowski added that clean, properly balanced coolant, whether applied as a mist or flood, is also critical to avert blade breakage. “Saw blades cut because they are harder than the material they are cutting. If dirty or weak coolant doesn’t keep them cool, the heat generated from the cutting process can cause the blade material to soften. When it loses its strength, it starts to dull and can stop cutting.”

Gordon recommends always using a coolant designed for the band saw process. A milling, drilling, or turning coolant, no matter how high the quality, won’t necessarily work well. The coolant-to-water ratio of the band saw coolant should never be less than 10-to-1 and ideally be closer to 5-to-1.

Cutting too slow or too fast is detrimental to the blade. “Too little pressure will wear out the tips of the teeth by grinding away their edges without cutting chips. Too much pressure overloads the teeth and can result in tooth breakage. An improper feed rate can lead to the same conditions,” Gordon said. “Tension can also be too high or too low. Too high will lead to stresses that induce cracking and premature blade breakage. Too loose can also lead to stress cracking and cause crooked cuts that often result in prematurely replacing blades.”

A productive band saw blade needs support. According to Herzog, the blade guides should support the band and roller guides and be tightened so they barely turn by hand. The guide arms should be as close as possible to the work. Cleanliness and the condition of the guides are also important. A guide that is worn or packed with chips can cause wear on the sides of the blade. That wear can lead to stress cracks and blade failure.

Blade life can be extended from 25 to 50 per cent if time is taken to break it in. Lacroix said that 70 per cent of the shops he works with have reduced scrap and increased blade life by consistently breaking in new blades. “Think of it like breaking in the tip of a very sharp pencil,” he said. “A new blade can have razor-sharp tips that aren’t yet ready to withstand the cutting pressure that is present in a production sawing operation. The teeth will last much longer if you take the time to hone them properly. The break-in process puts a radius on the teeth so they can limit the microscopic damage that can significantly reduce blade life.

“There are different methods to break-in a blade. One method is to reduce the feed rate to a level that is between 20 and 50 per cent of the target rate. Start the first cut at that reduced rate. Once the blade is fully immerged[EMERGED?] in the workpiece, you can start to increase the feed rate slowly. With each subsequent cut, you can gradually increase the feed rate until you reach the desired cutting rate.”

Reduce Operator Failure: Train and Maintain

A multitude of details are involved with band saws and keeping their performance on the cutting edge. But the single biggest variable, said Herzog, is the operator.

Training is essential. Turning to equipment and blade manufacturers for training can provide a solid understanding of the equipment and a basic understanding of materials being cut.

Every material has an ideal cutting range. “An operator needs to know the band saw, and he also needs a basic understanding of the material being processed,” said Borowski. “He needs access to hard copies, websites, or an app where he can refer to cutting charts to identify the proper band speed and feed rates. He needs to understand how and when to adjust the sawing parameters to get the correct cutting rate. In some ways, it becomes an art.”

Experience will help an operator become comfortable with making adjustments that will guarantee the most cuts per shift.

“A knowledgeable operator can produce more straight cuts faster and anticipate blade failure that saves a lot of time and avoids producing scrap,” said Lacroix. “For example, if an operator familiar with the saw and the process knows he typically gets 50 cuts from a blade, he can closely monitor the cut times and part finish at cut No. 40 or 45. If the blade isn’t providing the desired results, he’ll know to replace it before it fails mid-cut. That will save a lot of time, money, and certainly frustration.”

DoALL Sawing Products, 888-362-5572, www.doall.com

LENOX, 800-642-0010, www.lenoxtools.com

Simonds Saw, 800-343-1616, www.simondsint.com

The L.S. Starrett Company, 978-249-3551, www.starrett.com

About the Author

Sue Roberts

2135 Point Blvd

Elgin, IL 60123

815-227-8241

Sue Roberts, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. A metalworking industry veteran, she has contributed to marketing communications efforts and written B2B articles for the metal forming and fabricating, agriculture, food, financial, and regional tourism industries.

Roberts is a Northern Illinois University journalism graduate.

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Hypertherm Associates partners with Rapyuta Robotics

Gema welcomes controller

Protected and productive: welding helmet tech

HGG Profiling Equipment BV names Western Canada area sales manager

- Industry Events

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada