- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Fiber or CO2 — do we have a winner?

Fiber lasers are encroaching on the territory once held by CO2 lasers... so which is the best for you?

- By Nestor Gula

- March 6, 2014

- Article

- Fabricating

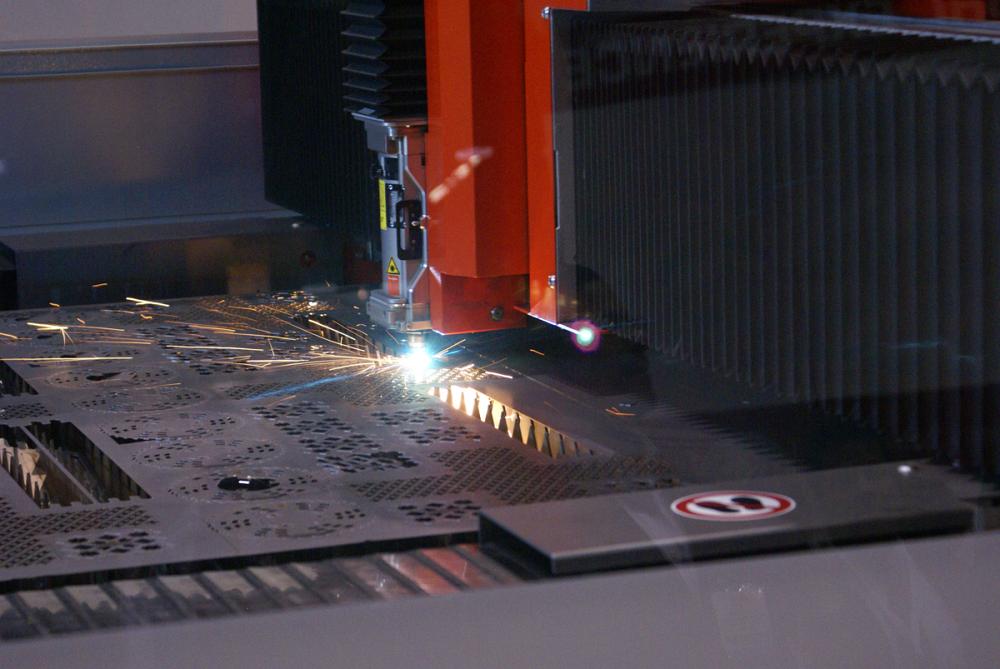

While not new, fiber lasers are really coming into their own as prices fall and their capability increases. Once only able to cut thin material, fiber lasers are now competing with CO2 lasers since they can now cut thicker material and are more flexible for different manufacturing environments.

“Any industry that uses a CO2 laser or turret punch to manufacture part or blanks should look into a fiber laser,” says Nicholas McCauley, Fiber Laser Specialist at Salvagnini.

“I am not saying that it will be a perfect fit for all who look. We think that fiber lasers especially fit for subcontracts, furniture manufacturing, food equipment manufacturing, HVAC, electrical enclosure manufacturing, and elevators.”

Fiber laser’s prime advantage is that they can cut thin metals very fast, up to 2-3 times that of the same wattage CO2 laser.

“This is due to the wavelength of the laser and smaller kerf which result in less material needed to be removed from the cut,” says Matt Garbarino, Marketing Manager for Cincinnati Incorporated.

“Companies that process mostly thinner metals, either mild or stainless steels will see the largest productivity gains using this technology.”

If a manufacturer cuts many different types of metal, a fiber laser can accommodate this need. “If you need to cut highly reflective materials such as brass and copper, CO2 lasers are usually not an option whereas fiber lasers can easily cut these materials,” said Sanjay Garg, Senior Engineer on the laser team at Hypertherm.

Highly reflective materials will almost completely reflect the 10.6 micrometer wavelength of the CO2 laser. Major speed increases can be had when cutting stainless steel and even aluminium. “One interesting area is in cutting galvanized steel — fiber seems to cut better in galvanized steel than CO2 — so any industry using galvanized can benefit — agricultural manufacturers of grain bins, for instance, said Jeff Hahn, national laser product manager, MC Machinery Systems Inc./Mitsubishi Laser.

“Just like in other materials, you’re cutting faster in galvanized steel, meaning automation could be coming into play for those who hadn’t previously considered it. The idea is to ensure manpower isn’t the bottleneck, as a standalone machine will process material faster than you can load and unload it.”

Fiber lasers have a shorter wavelength (1 micrometer) and higher beam quality than industrial CO2 lasers.

“Taken together, this means that the beams from fiber lasers can be focused to smaller spot sizes than can the beams of CO2 lasers,” said Terry VanderWert, President of Prima Power Laserdyne.

“Therefore, fiber lasers are more effective for applications that benefit from narrow cut width, small hole diameter, and narrow welds.”

[gallery type="slideshow" ids="102339,102338"]

Cost advantage:

Fiber lasers are very efficient cutting systems and can lead to great savings, meaning greater profit, in terms of increased productivity with the added advantage of savings in energy costs.

“Operating costs are 50% lower with fiber technology mostly due to the higher electrical efficiency of the fiber source. Fiber lasers do not use resonator optics or beam path delivery optics,” said Frank Arteaga, Head of Product Marketing at Bystronics.

“Fiber laser uses fiber optic technology to both create the laser beam and also deliver the beam to the cutting head, eliminating the need to replace optics on a periodic basis.”

There is no laser gas, no internal mirrors and no moving parts in a fiber laser.

“This lowers cost of maintenance and downtime for maintenance,” said Jason Hillenbrand, Laser Product Manager at Amada America Inc. “Additionally, fiber will use anywhere from 1/3 to 1/4 the amount of electricity as a CO2. In many states, energy credits have been provided to our customers for installing our fiber laser. Significant credits.”

“If you really want to take advantage of the fiber laser capabilities than you should opt for a high dynamic fiber laser machine that permits high speed processing. Those machines incorporate most of the time linear motor technology which is not inexpensive and can explain a higher machine cost of 25% or more versus an average CO2 laser system,” Stefan Colle, Laser Product Sales Manager at LVD Strippit.

“However the running cost with a fiber is significant lower versus CO2. Because of their design, fiber lasers require virtually no maintenance. Due to a higher efficiency (30%) versus 10% with the CO2 laser the fiber lasers are saving a lot of energy cost versus the CO2 laser.”

Capital costs can frighten some manufacturers away from fiber lasers.

“While solid-state lasers typically require a greater initial investment, they can be substantially cheaper machines from both a cost of ownership perspective, as well as from a cost-per-part perspective,” said Brett Thompson, Sales Engineer, TruLaser Product Group at TRUMPF Inc.

“There is less variability in the process. Because of the consistent nature of the solidstate laser cutting process, there’s less cost associated with things that are typically more difficult to quantify, such as downtime due to focal checks, nozzle centering requirements, et al.”

[gallery type="slideshow" ids="102337,102335"]

Weighing the options:

While a fiber lasers forte is on thinner material recent advances have made the systems much more flexible. It really depends on your definition of thin.

“The fiber laser can cut a similar range of material types and thickness as the CO2 laser,” said Marc Lobit, Marketing Manager for Mazak Optonics Corporation.

“However when material thickness are greater than 12mm, particularly in mild steel, the CO2 laser can provide a slightly better edge quality and in some cases faster processing speeds in thicker steel applications.”

The 1 micron wavelength of the fiber laser produces a smaller spot size and resulting kerf.

“This needs to be addressed when cutting thicker materials which require a wider kerf to expel molten material," said Bob Kloczkowski, Regional Sales Manager for Rofin-Sinar, Inc.

“Advanced cutting techniques and parameters can overcome this issue. Depending on the OEM or integrator of the fiber laser cutting system, the cutting techniques are an important factor to consider. “With the introduction of BrightLine fiber, there are fewer limitations in the material type and thickness solid- state lasers can process with speed and reliability,” said Thompson.

“A sheet metal part cut from 2-inch stainless steel, for example, is only possible with a CO2 laser, while copper can be processed only on a machine with a solid-state laser. This shows a grey area still exists, but BrightLine fiber has made the gap much smaller.”

[gallery type="slideshow" ids="102346,102345,102344,102343,102342,102341,102340,102350"]

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

CWB Group launches full-cycle assessment and training program

Achieving success with mechanized plasma cutting

3D laser tube cutting system available in 3, 4, or 5 kW

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

Welding system features four advanced MIG/MAG WeldModes

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI