Business Development Manager

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

How to properly maintain press brake tooling

Investing in a storage system and following some basic rules will extend press brake tooling life

- By David Bishop

- October 16, 2019

- Article

- Fabricating

Storage racks and load/unload arms are aligned with the press brake to a very high degree of precision. When used with tooling that has built-in rollers for ease of movement, even the heaviest of tools can often be moved in and out of the press brake with relative ease.

There are a few important things to remember to properly maintain your press brake tooling. The first is, don’t store it in a general storage rack away from the press brake when it is not in use. Storing press brake tooling in a general storage rack in the back of the shop, for example, is usually a serious productivity killer. It forces the press brake operator to step away from the press brake to retrieve the tooling required for the next job, or it puts the operator in the position of having to wait for the tooling to be delivered to the press brake when a forklift driver or setup person is involved.

When multiple press brake operators share the same tooling between two or more press brakes, it is common for tooling to get spread out over multiple locations. This invariably results in the press brake operators spending a lot of time searching to locate all of the individual tools that they need to run the next job. Needless to say, the amount of time consumed while doing this can really add up over time.

Implementing a Tool Storage System

For these reasons, it is always better to store your press brake tooling in an organized tool cabinet at the press brake where it will be used. In shops with limited tooling requirements, it’s best to share one dedicated tool cabinet between two press brakes when possible.

The second, yet equally important, thing to do is to invest in a tool cabinet that is designed specifically for storing press brake tooling. Storing press brake tooling in a general storage rack leaves it out in the open, exposing it to airborne dust and debris and much greater potential of damage. Handmade wooden storage units with individual slots for each press brake tool might seem like a good idea, but in fact they promote rust and corrosion as wood contains moisture.

Tool cabinets that store press brake tooling in a horizontal position and separate them with metal dividers are not always a good idea, either, as the metal dividers often cannot be arranged to provide a snug dedicated storage space for each press brake tool. As a result, the individual punches and dies may move around as drawers are opened and closed and punches and dies are taken in and out of the cabinet, thus exposing the working surfaces on the tools to potential damage as they come into contact with each other. The damage that occurs to punch tips and the shoulder radii on dies often results in sheet marking during bending. Obviously, this can present a big problem when bending materials that frequently go unpainted, such as aluminum, stainless steel, copper, and brass.

Experience has demonstrated that press brake tooling cabinets that store the tooling in a vertical position using nylon, neoprene, or polyurethane pads with individual tool slots provide the best overall method of storing tooling in an organized manner, while providing the maximum amount of protection from potential damage. And finally, a good tooling cabinet will come with lockable drawers to protect your investment and to keep your tooling from being moved away from its intended location.

The Importance of Portability and Safety

Another important factor for the implementation of proper press brake tooling storage is the portability of your tooling cabinets. As shop floors are reorganized to allow for the introduction of new machinery or for better work flow, it is important that your press brake tooling cabinets be easy but safe to relocate. Some are provided with wheels, thus making them easy to move. But putting wheels on press brake tooling cabinets is generally discouraged, as moving a heavy tool cabinet across a shop with uneven floors or potential hazards can be dangerous. Also, if the person moving the wheeled cabinet forgets to set the brakes on the wheels after moving it to a new location, it could potentially present a safety hazard if the shop floor is not level or if the tool cabinet is allowed to move as tools are being loaded and unloaded.

Obviously, safety must be the most important consideration when implementing the use of any press brake tooling storage system. As these cabinets are designed to store a lot of weight, it is critical that they be provided with interlocks that prevent more than one drawer from being opened at a time. This feature is critical because when two or more loaded drawers are opened, it presents an extremely unsafe condition in which the cabinet with the extended drawers and tooling could potentially fall toward the person that is loading or unloading tooling from the cabinet, thus exposing them to potentially serious injury.

Cross-Plant Tool Management

While it is rare, some large manufacturers move press brake tooling between manufacturing facilities as they shift work flow between locations. They do this to take advantage of unused capacity, to move the job closer to the customer, or to take advantage of facilities that provide greater efficiency and/or lower manufacturing costs.

While this can provide a significant savings in their overall tooling costs, it tends to make more sense when very specialized tooling is required. This is due to the fact that special press brake tooling can be very expensive and frequently comes with long lead times. However, it also exposes it to far greater potential of being lost or seriously damaged while in transit.

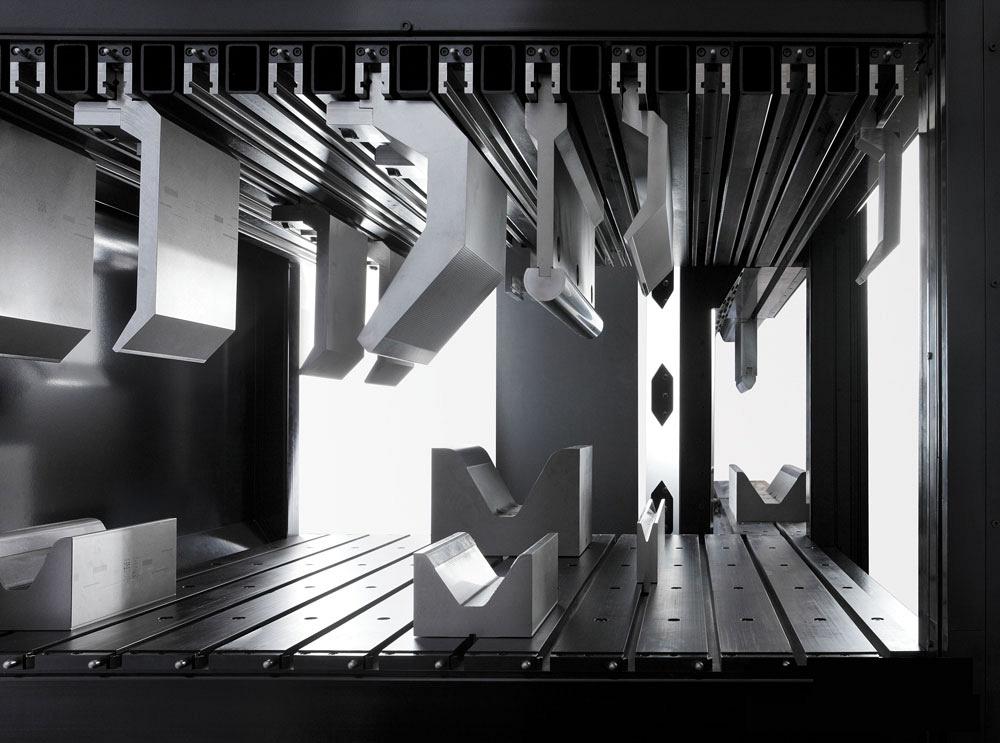

A storage system, like the Wila Heavy Duty (HD) version of the ToolStation, makes it possible to load and unload tools without any operator lifting while providing maximum safety.

Unless proper planning is done, it is likely that the facilities that engage in this practice will occasionally find themselves in receipt of expensive, one-of-a-kind press brake tooling that they have no way to store properly, which potentially leaves a highly valuable asset vulnerable. This is something that should be addressed at the beginning of the program, not once it has been implemented.

Dealing With Large, Heavy Tools

While press brake tooling cabinets represent a great option for storing and managing standard press brake tooling inventories, often they are not well-suited for the unique challenges of storing large, heavy-duty tools. Fortunately, there have been new developments recently in the storage and the loading/unloading of these heavy tools in and out of press brakes. Some of these systems comprise large storage racks that are designed to sit at either end of a press brake and use load/unload arms that can be moved by hand between the tool storage slots in the storage rack and the upper clamping system and crowning system or die holder on the press brake.

These storage racks and load/unload arms are aligned with the press brake to a very high degree of precision. When used with tooling that has built-in rollers for ease of movement, even the heaviest of tools often can be moved in and out of the press brake with relative ease.

Proper Tooling Maintenance

Because press brake tooling is made of steel, it is prone to rust and corrosion. This places a premium on keeping it clean and free of moisture, handprints, and the acid that is found on human hands. Simply wiping it down with a petroleum-based lubricant after handling it will not do the job. All that will accomplish is to cover the tooling and the handprints with oil.

The correct way to keep press brake tooling clean and free of rust and corrosion is to apply the following steps:

- After each handling, wipe it down thoroughly with a clean rag that is lightly soaked with isopropyl alcohol. This will eliminate the handprints and acid that are left behind by human hands.

- While wearing gloves, coat the tool with a preservative lubricant and wipe off the excess.

- Place the tool in a tool cabinet.

- Another option is to wipe down the tooling with a cleaner/preservative before placing it in a tool cabinet.

- Make sure that the tool cabinet has at least one package of silica gel in it. In environments with high humidity levels, use at least two packets of silica gel.

Taking these steps will not only keep your tooling clean and free of rust and corrosion, but will also protect the laser marking that contains all of the important technical data that is used to identify it and make it possible to load it into the control on your press brake.

Protect Your Investment

Precision-ground and hardened press brake tooling produced from high-quality steel is no longer a perishable good. Rather, it is a durable good that, when used and cared for properly, will provide at least 10 years or more of service life with accuracy that is very close to or the same as it was when it was purchased. It represents a significant investment.

While some first-time precision press brake tooling purchasers may try to avoid the cost of purchasing a tool cabinet with their tooling, after they have had a few pieces of their new tooling get damaged, they quickly come to realize that the cost of damaged tooling will soon outweigh the cost of a tool cabinet. As this happens, the overwhelming majority of them will purchase a tool cabinet to stop the cycle of damage to their tooling.

Like anything of value, it only makes good sense to protect your investment and store it and use it wisely so that it provides you with the maximum return on that investment.

David Bishop is a business development manager for Wila USA, 7380 Coca Cola Dr. #109, Hanover, Md. 21076, 443-459-5496, www.wilausa.com.

Press brake tooling cabinets that store the tooling in a vertical position using nylon, neoprene, or polyurethane pads with individual tool slots provide the best overall method of storing tooling in an organized manner, while providing the maximum amount of protection from potential damage. This four-drawer configuration would typically be used to store tall punches. When short- to medium-height punches and dies need to be stored, the cabinet can fit five drawers.

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada

DiPaolo Machine Tools Open House 2024

- June 4 - 5, 2024

- Mississauga, ON Canada

FABTECH Canada

- June 11 - 13, 2024

- Toronto, ON Canada

Zoller Open House & Technology Days 2024

- June 12 - 13, 2024

- Ann Arbor, MI