Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Streamlining air delivery

Tripar brings hybrid fab approach to the aid of air vent designer Aria

- By Rob Colman

- December 8, 2022

- Article

- Fabricating

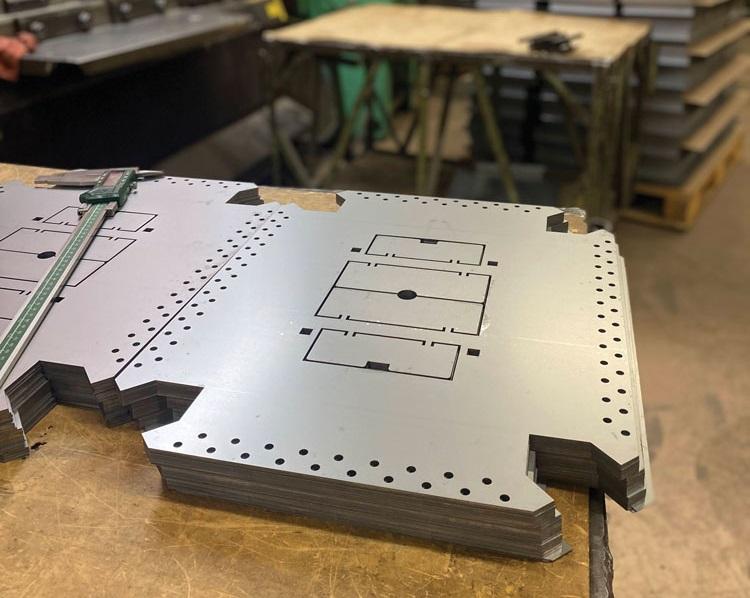

“When we started working with Aria, quantities were small enough that we were laser cutting them and doing all the forming work on our press brakes,” said Sevack. Tripar

Tripar, a Montreal-based metal components manufacturer, has been in business for more than 70 years. Like any company trying to stay competitive, it is looking for new ways to branch out in the industry. Sometimes serendipity plays a role.

This was certainly the case when Lauren Sevack, the company’s administrative director and a third-generation member of the family business, connected with vent company Aria.

“I was renovating my home when the contractor told me, ‘You have to see these vents,’” she said. “I thought, ‘What could be so special about them?’ But they really do stand out as a unique design element. And I found out on their website that they are designed and made in Canada.”

Family Connections

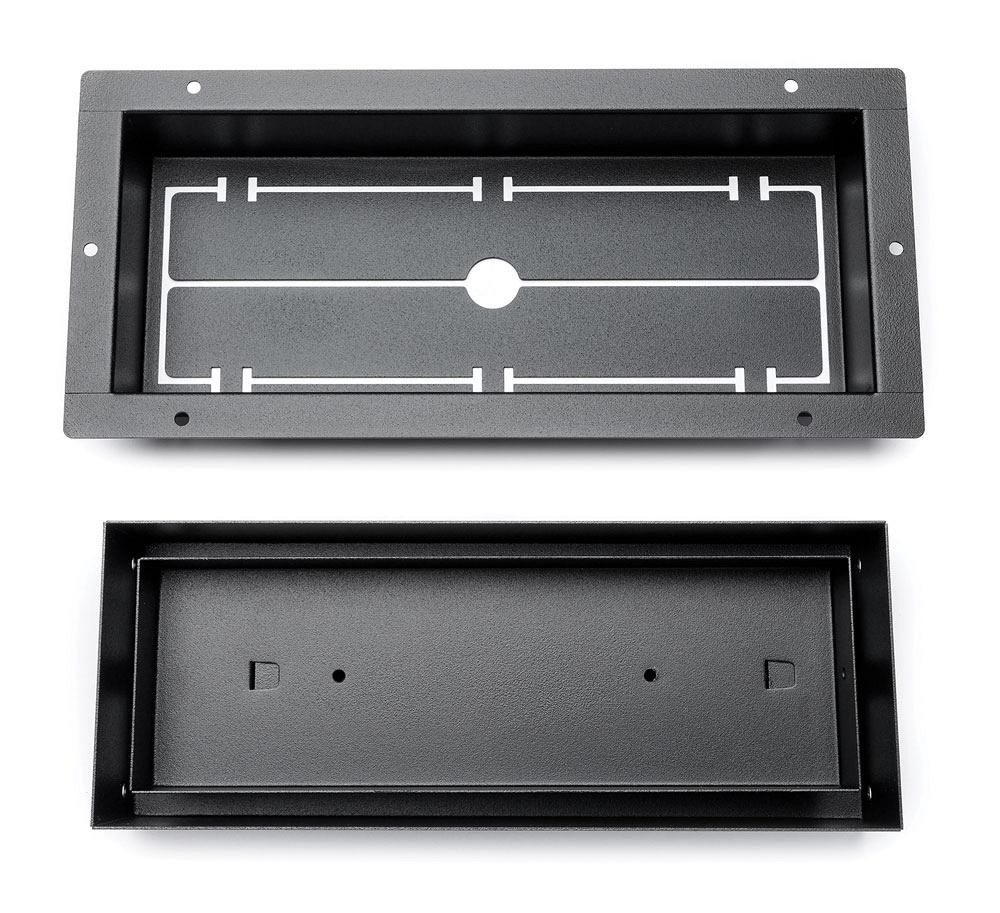

Aria Vent’s floor vents and exhaust covers integrate the flooring or ceiling design so that instead of having a standard air register, it simply appears that a portion of the floor has a cut-out around it. After noting that the structure of the vent is metal, Sevack looked further into the company.

“It turned out that the designer Paolo Mantenuto founded the company with his daughter Roberta, who now serves as CEO of the company. So, in many ways they are in a similar situation as I am with my father Lloyd,” said Sevack. “Both Lloyd and Paolo are engineers and keen inventors of new ideas for their businesses.”

Mantenuto had started his life in Canada in 1987 importing tiles from Italy. Fifteen years later, he and his wife started a business manufacturing and installing high-end marble and granite kitchens, countertops, and fireplaces.

“A customer of that business wanted to cut slots out of stone to create custom grills for airflow,” said Roberta Mantenuto. “Paolo discouraged him, explaining that having those grills waterjet cut would be too costly. It was this that led him to design his first vent concept. The customer didn’t like the concept but Paolo knew it was worth pursuing. He went about patenting the designs and creating a basis for developing a website. It was then that he called on me to begin work on the marketing side. We had five years of solid growth behind us when we first made a connection with Tripar.”

Aria was different in many ways, really. The company was out making vents “sexy,” building its brand not through wholesalers initially, but via e-commerce.

“It’s opposite to the business model of our main competitors,” said Mantenuto. “In the past few years when other companies in the industry started building social media presences and more advanced websites, we had already been in that space doing so successfully for five years because nobody else was.”

When Sevack reached out to Paolo, he was keen to speak to her about how they might work together. It turned out that Aria, based in Toronto, was working with a local fab shop that was reaching capacity. It was time for them to scale up.

“We knew the potential of their business because of how they’d grown year over year,” said Sevack. “So, we designed a technical package to show them what they’d need to go forward. Our engineering team put together precise drawings geared toward design for manufacturability. When they liked what they saw, we started producing several of their models, including paint, assembly, and packaging for customer delivery.”

Hybrid Fab Options

Sevack points to Tripar’s hybrid approach to metal fabrication as key to drawing in customers like Aria.

“When we started working with Aria, quantities were small enough that we were laser cutting them and doing all the forming work on our press brakes,” she said. “But once their volumes got to a certain level, we encouraged them to invest in tooling for stamping. Time per piece went from a few minutes to a few seconds. Now, the most popular items are flying through our machines.”

Mantenuto concurs that this was a big part of the attraction of working with Tripar.

“We hadn’t connected with any other company that had this hybrid model,” she said. “We looked at the cost of having die sets made for our products before but the quotes we got were so astronomical, they just didn’t make sense for a company like ours. Working with Tripar, we were shown that production could be optimized by using dies for certain parts of the production. That’s what we’ve done, bridging the process so we can scale at a reasonable rate without investing a fortune in tooling.”

Tripar operates a 65,000-sq.-ft. shop equipped with stamping presses and extensive metal fabricating equipment, and they’ve really made their name in manufacturing commercial and architectural lighting components. The company currently has over 1,600 dies and about 100 presses with a maximum capacity of 200 tons. With two shifts running six days a week, Tripar currently has approximately 65 employees.

“We’ve really done almost all we can to develop business in the lighting segment, though,” said Sevack. “It’s important that we continue to branch out into other industries, which we have concentrated on over the past few years. And building relationships like the one we have been forming with Aria is key to that.”

The design for manufacturability process is central to this.

“We want to make sure the part isn’t over-engineered and the design makes the most sense based on the application,” she said. “Now, every time they design a product, they ask for our input. We always think of ourselves as collaborators, and this is a good example of that.”

Supporting the Customer

Sevack suggests that it’s this close connection with customers and supporting the development of their products that has helped them navigate recent market obstacles.

Here we see the component parts of the vent assembly. When Tripar’s Lauren Sevack saw that the product was one that suited her family’s company operations, she reached out to the owners. Aria Vent

“We were able to walk our customers through some of the challenges of the past years,” she said. “Between that and our mix of CNC and stamping capabilities, we have many ways to support customers that they appreciate.”

Tripar also can point to consistency in its team as a benefit.

“Our longest-serving employee was with us for 46 years,” she said. “I think that says a great deal about the sort of company we are. I worked in the factory when I was 14, and I consider our team as a family. Likewise, that’s what drew me to Aria. It’s that similar focus on family connection that felt like a great fit for our working relationship.”

Aria doesn’t have quite the long history that Tripar boasts, but connection—family and otherwise—has been an important piece of their growth.

“It’s been connections with customers that have helped us grow our business over the years,” said Mantenuto. “Our first fabricator, who we still work with, was firstly a customer of my father’s stone business. Our products found their way into Home Depot because the buyer for the company contacted us after purchasing the product for his own home. Similarly, that’s how our first connection with Tripar occurred. It’s serendipitous, and we’ve grown from that.”

Like Tripar, Aria has reached a certain stage of growth, where pushing into new market niches is important.

“What we did with vents we want to expand to other building products,” said Mantenuto. “Our company mission is reimagining mundane, unloved building products. So, a big push this year has been in accessories—anything that hangs off your wall or ceilings: light switches, alarm keypads, thermostats, etc. We want to reimagine how people view all those things.”

Editor Robert Colman can be reached at rcolman@canadianfabweld.com.

Aria Vent, ariavent.ca

Tripar Inc., www.triparinc.com

About the Author

Rob Colman

1154 Warden Avenue

Toronto, M1R 0A1 Canada

905-235-0471

Robert Colman has worked as a writer and editor for more than 25 years, covering the needs of a variety of trades. He has been dedicated to the metalworking industry for the past 13 years, serving as editor for Metalworking Production & Purchasing (MP&P) and, since January 2016, the editor of Canadian Fabricating & Welding. He graduated with a B.A. degree from McGill University and a Master’s degree from UBC.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

CWB Group launches full-cycle assessment and training program

Achieving success with mechanized plasma cutting

Hypertherm Associates partners with Rapyuta Robotics

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI