Press Brake International Sales and Design Supervisor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Troubleshooting for aesthetic surface requirements

6 ways to prevent marks and gouges during the bending process

- By Steve Brown

- January 19, 2022

- Article

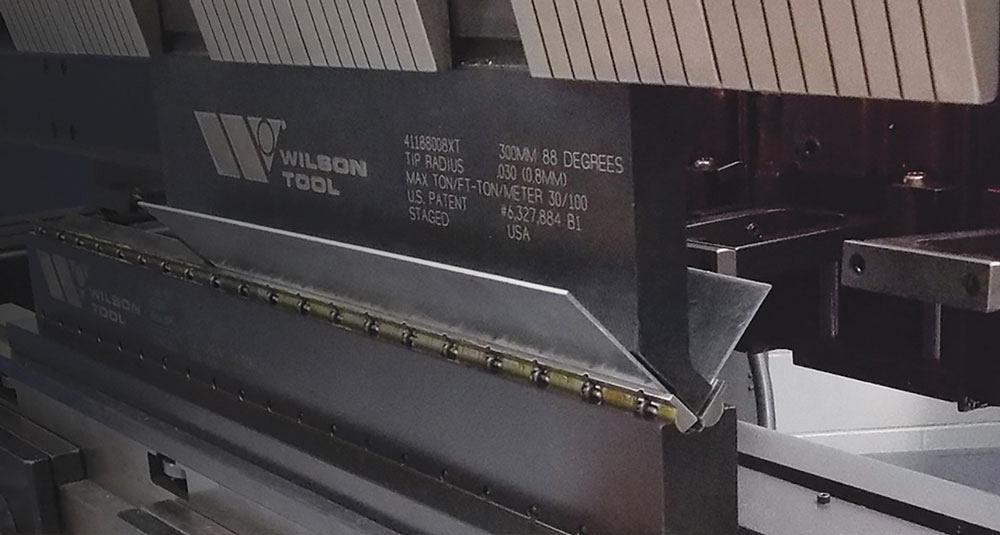

- Fabricating

With V-Series Back press brake dies, the concentrated load rests on a flat material being bent to a flat die shoulder that pivots with material—flat against flat rather than flat against a concentrated radius.

For fabricators working with cosmetic surfaces, it’s important to ensure that the finished products look nice and meet customer requirements. Sometimes light surface rubs from the shoulder of a press brake die can be acceptable or covered with a coat of paint. But for the typical part that is visible to customers and needs to look perfect, there can be no gouges, scratches, or scrapes. To achieve an acceptable surface finish, an extra level of care may be required.

Expensive materials like aluminum and stainless often need a showroom finish. Here are some simple steps to take when bending to get the finish on these parts right the first time and prevent costly part rejection.

1. Know Your Customer’s Expectations

The definition of a mark-free finish can vary from customer to customer. Marking could include marks, distortion, and angle, depending on the application. To clarify expectations, ask the customer for a sample part or something that has an acceptable finish. If no sample part is available, take the time to discuss what the part is used for, and then bend a section of material and give your customer a sample for approval.

2. Know Your Material

Aluminum and stainless come in a choice of surface finishes, such as polished or brushed, and the materials vary in hardness. The metals’ properties and surface finish will determine how much you need to protect it from your press brake die. Highly polished metal will show marks more readily, so you might want to pay a bit extra for a PVC coating on the material, pay attention to the shoulder radius on the die, or use a protective drape over the die shoulders. Keep in mind that PVC coating has an upcharge and may need to be removed before delivery to the customer.

3. Keep Tools Clean and Precise

Pay attention to how your tooling segments match in height. Non-precision tooling bending stainless with a protective PVC layer will get rid of the scraping, but you will still get dimpling if the tooling heights don’t match up. Stick with precision tooling for these applications.

Keeping your tooling clean and operable will help ensure bend accuracy and reduce marking. This takes time, but the cost isn’t even close to the cost of bad parts. Clean and inspect the tooling regularly, checking for nicks, chips, and debris. Aluminum is notorious for leaving residue on tooling, and any galvanneal that transfers from galvanized material must be removed from the die to achieve mark-free bending.

4. Choose a Larger Shoulder Radius

Choose a die with a larger V opening to help reduce tonnage and isolate pressure. In addition, a large die shoulder radius will create a surface for the material to slide; a sharper shoulder tends to grab the material. A good rule for the die shoulder radius is two to three times material thickness. Smaller radii—0.19 or 0.039 in. are common—tend to grab and mark not only unprotected material, but also material with PVC coating. If you have the correct shoulder radius, you may not need a PVC coating or urethane or cloth die drape.

5. Use a Urethane or Cloth Drape

A urethane or cloth drape over the top of the die will most likely eliminate marking.

Urethane drape tends to have some elasticity, but it is not like a rubber binder. With a durometer around 90A, which is fairly hard with minimal stretch, the drape wears fairly well, assuming the material has a clean edge from punching or laser cutting. Make sure to account for the urethane thickness when determining the V opening size. Sheets are typically 0.01, 0.027, or 0.030 in. thick and 4 or 6 in. wide. Drape life can be extended by moving the sheet front to back as wear occurs.

Fabric drape tends to be less elastic than urethane and not as good for deep draw applications. At 0.012 in. thick and 4.7 or 9.5 in. wide, this material wears like iron compared to urethane and will prevent all marking. Fabric costs more per foot than urethane, but it lasts longer, making it more cost-effective.

A urethane drape can be fixed to the tool using magnets, which maintain adhesion even on greasy surfaces.

Selecting the proper V-opening (based on material thickness plus drape thickness) and having a large shoulder radius will maximize wear life of both drape materials. Drape is not meant to be pulled tight across the V opening but rather allowed to sag into the opening before bending to reduce stretch. Tape can be used to secure the drape to the die, but simple magnets can be a better choice. They work even if there is a little oil on the material and allow the drape to adjust without losing adhesion. Like the PVC-coated material, drape is an additional cost, but it doesn’t require any additional steps for removal after bending.

6. Use Specific Tooling

Special tooling can overcome some deficiencies of traditional tooling. For example, Wilson Tool’s V-Series Black press brake dies include replaceable built-in inserts that rotate so material glides on a flat surface, as opposed to the grabbing action of a traditional V-die shoulder radius. With these dies, the concentrated load rests on a flat material being bent to a flat die shoulder that pivots with material—flat against flat rather than flat against a concentrated radius.

Special tooling tends to cost more, but as volume and expectations go up, this tooling can help speed up production and increase quality. It can be custom-made from material that will help address marking problems as well. If composites are used to reduce marking, for instance, they usually are inserts that do not interfere with production like drape might.

While each one of these aspects is important, it’s essential that fabricators take a look at the whole picture when working with surface-sensitive materials and applications. Understanding the material type, choosing the right tooling for the application, opting for a drape, and working with a large shoulder radius can make the difference between good and scrapped parts.

Steve Brown is press brake tooling and additive manufacturing product manager, Wilson Tool International, 12912 Farnham Ave., White Bear Lake, Minn. 551110, 651-286-5806, steve.brown@wilsontool.com, www.wilsontool.com.

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Achieving success with mechanized plasma cutting

Hypertherm Associates partners with Rapyuta Robotics

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

Gema welcomes controller

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI