Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

5 steps to laser welding success

Planning your shift to laser welding works best with a solid plan

- By Rob Colman

- June 18, 2021

- Article

- Welding

Laser welding for general fabricating has come a long way in the past five years. At this point, it’s a tool that most fabricators understand is a potential method to increase part throughput by speeding the welding process and eliminating post-processing requirements.

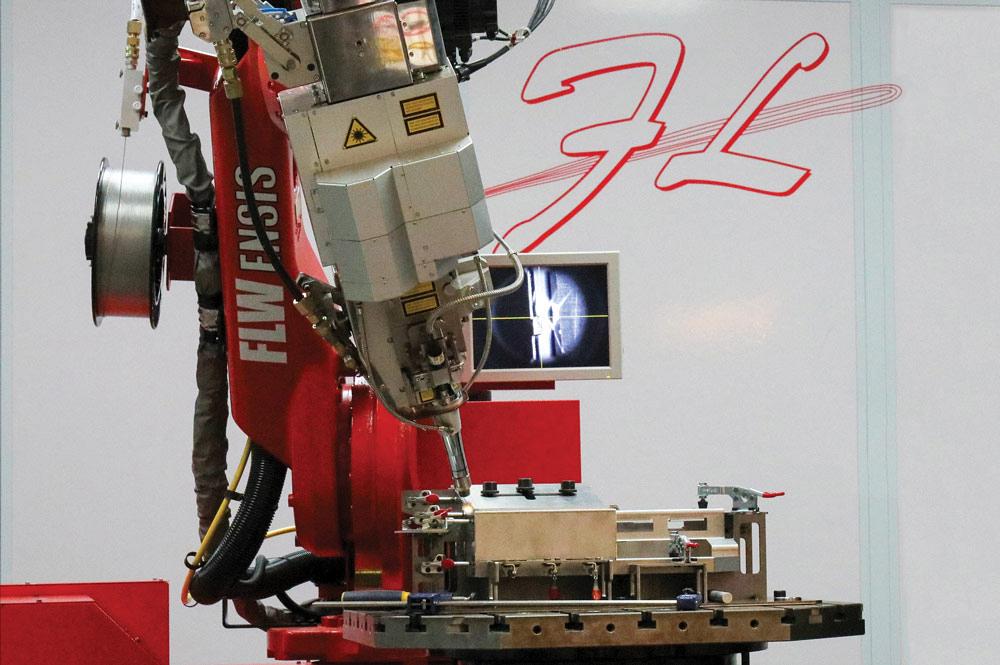

“The past year has been a busy one in the market,” said Dan Belz, FLW product manager for Amada America. “People are looking for alternative technologies because they can’t find welders, and for many manufacturers this technology makes a lot of sense.”

At the same time, enthusiasm for the technology doesn’t always match precisely the needs of a particular shop. Belz discussed with Canadian Fabricating & Welding five steps to ensure your laser welding project will be a success.

1. Review Your Materials

Laser welding initially seemed best suited for stainless steel, which can be awkward to weld and requires a pristine finish on completion.

However, now the ability to manipulate the focus of the laser beam allows deeper penetration in mild steel too with the use of a deep-penetration (keyhole) welding technique, which might be compared to gas metal arc welding. The heat penetrates completely through the leading edge of the molten weld metal. As the heat source progresses, the molten metal fills in behind it to form the weld bead. With this technology, shops can achieve a stronger weld (load per weld bead area). And because the heat input into the workpiece is much lower than with GMAW, the weld is less susceptible to issues such as cracking. Lower heat also means lower distortion on the part.

“About 90 per cent of the projects we’re working on with customers use this deep-penetration welding technique,” said Belz.

But as Belz explained, once the metal gets over a certain thickness, the payback just isn’t there.

“Anything bigger than 1/8 in. we generally don’t encourage,” he said. “That thickness on aluminum, for instance is the maximum we’ll do in that material for good penetration. We can certainly weld mild steel from 1/8 to ½ in., but the weld specifications for many jobs in these thicknesses don’t suit a laser welding system.”

2. Solidify Your Design

The development of an assembly can take time, but before you can consider a part for laser welding, the basic design has to be solidified.

“If you make a design change late in the game, that might mean the fixture you’ve created for the part won’t fit. A fixture is designed for precise specifications; you can’t change that on a dime. Make sure the essential design is set. Once you start working on fitment, some details might be altered but that will be strictly related to process choices, not the shape of the final assembly.”

3. Consider Your Fitment

Once you’ve got a design finalized and ready to go, consider how it can run most efficiently through your full manufacturing process. It may be that once you switch an assembly over to laser welding, how the individual parts of the assembly are formed may change.

“One customer of ours added 30 in. of weld to one of their assemblies because it saved them more time not having to bend individual sections,” said Belz.

As Belz explained, fitment decisions usually don’t mean redesigning a part.

“Sometimes you simply have to tweak a design for proper fitment,” he said. “In one case, where a customer was building a lamp using three parts in a fixture, we did redesign it fairly significantly for welding. But it didn’t change the shape of it, it simply involved changing how they slot-tabbed it and other adjustments to minimize any potential for distortion.”

4. Consider Fixturing Options

Once the design and fitment are locked in, it’s possible to design your fixturing for best fit. Fixturing is seen as the big hurdle to adopting laser welding, but a variety of options are making it easier to create fixturing relatively promptly. Because distortion is much less a concern with laser welding compared to traditional welding, for instance, fixtures can be made from sheet metal.

Additionally, automated fixturing options have been developed that can speed up part changeout times.

Once a fixture is created, the repeatability creates its own advantages of speed and accuracy.

Once your shop is comfortable with the technology, you also can get more creative with fixturing. Some have created adjustable fixtures for products of different sizes.

However you approach fixturing, Belz said that it’s important to remember that it is key to working with the technology.

“Success with laser welding all comes down to fitment and fixturing,” he said.

5. Think Outside the Box

Belz considers thinking creatively to be critical in getting continuous value from your laser welding investment.

“Customers that have already invested in the machinery are finding new ways to do other work using laser welding, and we work with them to fine tune those innovations,” he said. “For instance, one customer has started to do stitch welding on a lap joint. The weld is being done on thin-gauge aluminum, so a stitch weld is necessary to avoid creating any deformation in the material. The customer engineered it so that a weld bead would be completed every few inches. This gave them the strength that they needed. Meanwhile, once we saw what they were doing, we were able to help them speed up the process by performing what we call a ‘flying shot’ across the part. The way the company had programmed the part, they were starting the weld, stopping it, then moving to the next weld in separate steps. A flying shot means that the head never stops moving; the laser simply pulses on and off as necessary.”

Belz said another customer had to spot-weld 22-ga. material without showing any bleed-through on the part. “The adjustability of the laser made it possible to make the panel look like it had been glued on,” he said. “Spot welding may sound like an application that wouldn’t benefit from laser welding, but doing this process with the laser welder shrinks the work group at this company from six people to two and has the potential to increase output from 1,500 assemblies a day to between 1,900 and 2,000.”

Belz has a very simple equation for when a fabricator should consider a laser welding system: “If between 40 and 80 per cent of your work is being touched by a welder, then you need to take a serious look at laser welding technology,” he said.

Editor Robert Colman can be reached at rcolman@canadianfabweld.com.

Amada Canada, www.amada.ca

About the Author

Rob Colman

1154 Warden Avenue

Toronto, M1R 0A1 Canada

905-235-0471

Robert Colman has worked as a writer and editor for more than 25 years, covering the needs of a variety of trades. He has been dedicated to the metalworking industry for the past 13 years, serving as editor for Metalworking Production & Purchasing (MP&P) and, since January 2016, the editor of Canadian Fabricating & Welding. He graduated with a B.A. degree from McGill University and a Master’s degree from UBC.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

CWB Group launches full-cycle assessment and training program

Achieving success with mechanized plasma cutting

3D laser tube cutting system available in 3, 4, or 5 kW

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

Welding system features four advanced MIG/MAG WeldModes

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI