- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

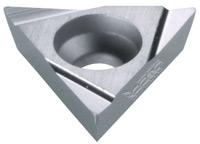

Cermet Tooling Explained

When surface finish requirements cannot be met, cermet tooling may be the answer

- November 1, 2010

- Article

- Management

Cermet tooling, as the name implies, is a cross between ceramic and metal tools.

Made of ceramic particles bonded together with a nickel binder, these tools are capable of running at higher speed than carbide tools, and are much more wear-resistant. The surface of these inserts is very smooth, allowing the chip to flow easily and prevent built-up edges.

Ceramic tooling traditionally has been used for high-temperature cutting, especially in hard materials. However, these tools are very brittle and can handle only light interrupted cutting. When combined with metal, the properties of the carbide tool allow cermets to deform slightly because it is not a true ceramic insert.

“The nickel binder can handle the heat that is generated in the cutting process better than the cobalt binder of carbide inserts. Heat is the enemy in any cutting application,” explained Iscar Canada Senior Product Manager Steve Geisel.

Cermets were invented for high-quality surface finishes, cutting with high spindle speeds (800 to 1,200 SFM), and cutting for a long period of time without interruption.

“While carbide tooling now can run at 1,000 SFM because of new coatings and substrates, they still cannot compete with cermet tooling in terms of surface finish,” said Geisel. “Less friction is created when using a cermet insert compared to a carbide insert, and this means less vibration.”

The more friction that is created, the more difficult it is to maintain a high-quality surface finish. According to Geisel, the only way to get close to the surface finishes created by cermet tooling is with a carbide insert with a wiper setup.

Coating Technology

Iscar’s cermets are physical vapor deposition- (PVD-) coated and multilayered, usually with titanium nitride (TiN), titanium carbonitride (TiCN), and titanium carbide (TiC). Cermet tooling also is usually sharp, which is why it is PVD-coated instead of chemical vapor deposition- (CVD-) coated.

“Coatings help extend tool life,” said Geisel. “Coated cermets will definitely last longer, and that helps control the costs of consumables.”

Tool life also is easier to predict with cermet tooling when compared to carbide, because the tool is engaged in the cut all of the time.

Cermet tooling is suitable for cutting carbon and alloy steels to tight tolerances, but can also be used to cut stainless steels and even high-temp alloys. It should not, however, be used to cut cast iron and aluminum.

Coolant Usage

A flood coolant setup is recommended for cutting with cermet tooling.

“The coolant lubricates the cut while cooling the chip,” said Geisel. “Because of the high cutting speeds achieved in the finish pass, more heat is generated. Coolant cools the area and creates an environment for proper chip control.”

Chip control is very important at this stage because the last thing you want to do at the finish stage is scratch the surface of the workpiece. There may already be many, many hours of machining in the part.

“People have definitely not forgotten about cermets even with all of the advancement in carbide tooling,” said Geisel. “Even though carbides have been making significant advances over the past few years, cermets are changing, too, with new chipformers and geometries available.”

For more information, visit www.iscar.ca.

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI