- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Preaching the Gospel of Manufacturing

Passion drives disciples of industrial education to align efforts

- By Sue Roberts

- September 25, 2012

- Article

- Management

Educators and manufacturers are working together to draw students to technology and trades programs. Photo courtesy of NAIT.

Skilled workers for industry have been at a premium, on and off, for at least half a decade. About 50 years ago the Red Seal Program was initiated by Human Resources and Skills Development Canada, and the province of Alberta established two institutions, one in the north and one in the south, to provide industrial trades training. Unfortunately, the ebb and flow of economics, offshoring and reshoring trends, and changes in attitudes have manufacturing needing more. More people. More training. More positive exposure.

Manufacturers, educators, and government entities are joining forces to attack the problem. Rather than just providing lip service and urging others to take action, they are aligning their efforts to develop strategies and programs to close the current skills gap and fill the pipeline with a qualified workforce drawn from today's younger generation. The mantra that manufacturing is a good career choice is being touted from the proverbial soapbox, with associations and organizations helping coordinate communications.

CIM talked with just a few of the disciples for an update on their activities.

Introducing the Good Life

Nigel Southway, manufacturing consultant, engineer, and author of Cycle Time Management, also serves as chairman of the Society of Manufacturing Engineers (SME) Toronto/Ontario Chapter, which introduced the Take Back Manufacturing (TBM) initiative last fall. The initiative brings together Canadian technical societies, management associations, trade organizations, and educational stakeholders to redefine perceptions of manufacturing and create a highly educated, highly trained workforce.

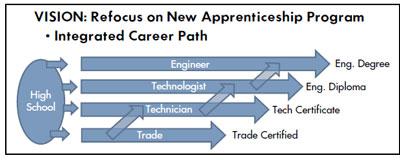

"We're not talking about craft or trade apprentices here," Southway said. "We're talking about what we call an integrated and fully functional apprenticeship program that is for every grade of skill, knowledge, discipline, and profession."

Southway's perfect world would see 16-year-old students entering the program that would combine engineering education, like that available at universities, with specific hands-on training and industrial sector experiences. "That engineer would have a superior level of engineering skill set because he would have the same knowledge and education as engineers coming out of university today but also hands-on experiences integrated with a specific industry."

To capture those 16-year-olds, Southway said we need to woo children beginning at 10 years old along with their parents. "Manufacturing is considered to be dark, dangerous, and smelly. That perception needs to change to reflect manufacturing now. Kids need to realize that they are not all going to be basketball players or rap artists and that they can be a manufacturing engineer, designer, or accountant. Those are good jobs that will pay well for their future. They need to know that if they get on the manufacturing train, they will have a good life."

Southway thinks industry has taken its "eye off the ball" as far as training, placing blame in two areas. The first area is the decline in needed capacity in recent years, and second is a lack of willingness to invest in education. "Manufacturers may invest in capital equipment, but they won't invest in education, yet education has much more of a productivity component to it than a piece of equipment. Corporations have plenty of cash right now. Divert some of that to an educational program. It should be a self-induced tax.

"We've wasted more than a decade on the idea that we're going to get rich on services and we all know it isn't working. The good news is that manufacturing is coming back to North America. The bad news is that even if we act now, we won't have the skills to support it. We've got work to do."

Connecting Employers and Educators

Robert Finlayson, instructor of fabrication and welding at Kwantlen Polytechnic University, Surrey, B.C., is also chairman of the Certified Education Center Council (CEC) of the Fabricators & Manufacturers Association Intl. (FMA).

Communicating that industry offers opportunities for innovation and needs advanced technological skills will help draw today’s students. Photo courtesy of NAIT.

"We're still fumbling around to a certain degree," said Finlayson. "In other words, some institutions have built up technology and trades programs with equipment and all the things you need to deliver a good program, but the seats weren't filled."

Finlayson sees a disconnect between employers and the educational institutions. "I think employers often take a short-term look at workforce education, especially the smaller employers who need journeypeople to fill an immediate customer order. We have to look at a longer career path and make it attractive so employers buy into that."

One initiative that shows promise is the Hamilton Skilled Trades Apprenticeship Consortium (HSTAC), drawing participating companies from the Hamilton, Ont., area. It has taken a somewhat different approach to hosting apprenticeships to assist employers who don't have a need or resources to support the five- to six-year apprenticeship program. "Multiple employers create a consortium to share an apprenticeship. It makes a lot of sense to get people trained and goes a long way to creating a career path where the journeyperson has multidisciplinary capabilities. If companies share apprenticeships, they get employees with better, broader skills that can pay off in a big way."

Another initiative is in British Columbia, where programs are providing core training by grouping a number of Red Seal trades in one entry-level program. The new apprentices coming from these programs have a broader-based skill set that opens more doors to full-time employment.

Multidisciplinary programs that would allow students to move from one trade to another and learn a range of skills are gaining favor with the apprentices and manufacturers. "Students like to move around and try different things. And that's what provides an innovative, more productive workforce," said Finlayson. "Obviously, you want somebody who can work on your shop floor today at a particular task, but that task will change over time, and we want to provide a workforce with the flexibility to meet changing needs."

FMA's CEC recently hosted a T.E.A.M. (Technology, Educators, And Manufacturers) Summit where educators and manufacturers agreed that they need to become better aligned. Participants recommended that one way to initiate this alignment is to encourage manufacturers to serve on education boards—right down to the elementary and high school parent groups. "By the time we get to the postsecondary level, we've lost opportunities to attract young people to industry. The damage has already been done. We need more interaction at the K-12 lower levels of education. Learning is so great at that age," Finlayson said.

Other successful training initiatives discussed at the Summit included Try Before You Train, a one-week, entry-level program at Thomas Nelson Community College in Hampton, Va. For US$300, a student experiences various skilled trades training to determine if one of them is the right choice as a career path.

Building a Pathway

Peter Lawlor, dean of the School of Trades at the Northern Alberta Institute of Technology (NAIT), in Edmonton, finds that the trades program pulls in fewer students straight out of school than those who have been in the workforce for a while. "It's a concern for us because we see folks leaving high school and bouncing around before deciding what they want to do. We see it as lost productivity."

In this coming academic year, NAIT will train more than 12,300 apprentices, and that doesn't include the full-time students in the certificate, diploma, and degree programs. "We train about 17 percent of Canada's apprentices so we clearly influence economic activity on a national level. We also assist other institutions and countries developing training systems."

Lawlor said that NAIT is working within the system to influence parents to encourage their children to pursue trades and technology programs. "We find that about 30 percent of high school students continue on to university, yet we struggle with creating pathways to trades and technology because the whole system is geared to the university pathway."

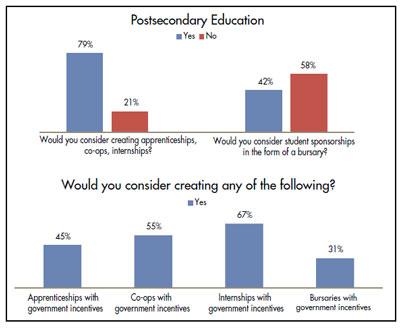

Results from a Network Skills Initiative survey conducted by the Canadian Chamber of Commerce from March to June of this year indicate both the need and willingness of employers to do more co-op and apprenticeship training. Forty-five percent of responses were from companies with one to five employees; 33 percent were companies with six to 50 employees. Charts courtesy of the Canadian Chamber of Commerce.

To create that route, NAIT is working with high schools to identify and align curriculum that will assist with transitioning students into the trades. High school students can receive credit for taking postsecondary courses and eliminate the need to retake those courses when they pursue further trades education.

"There is also an NAIT program called RAP [Registered Apprenticeship Program] that allows students to participate in apprenticeship training while they are in high school. While enrolled in the program, they receive high school credit, accumulate on-the-job training experience and hours, and even get paid. They can come out of the program with a high school diploma positioned for an apprenticeship and they end up in a NAIT program. Some students can write off their first-year government apprenticeship exam and come out of high school as a second-year apprentice."

NAIT is also working on ways to help people who are interested in learning a trade gain training.

"We should be front-ending apprenticeship. If people are having difficulty in finding work and business and industry are not hiring, we want to offer training that will be recognized. So we developed pre-apprenticeship programs that offer government-approved, first-year apprenticeship training without the usual, initial requirement of field experience.

"Participants get hands-on, practical experience here, plus the theory component which gives them a chance to challenge the first-period government technical training exam." Graduates then pursue an apprenticeship with the advantage of a knowledge base and prepared for the second period of training.

Finding alternative ways to deliver training is another NAIT focus; for example, offering the theory components of technical training as online courses. Called the blended-delivery model, face-to-face, hands-on training follows completion of the online segment. And for manufacturers who need to fine-tune their current workforce, the institute offers productivity enhancement training to help employees gain technical skills to use equipment effectively and to look for efficiencies within the operation.

Providing Financial Incentives

In an address this spring, Diane Finley, minister of Human Resources and Skills Development Canada (HRSDC), said that more than 50 skilled trades are included in the Interprovincial Standards Red Seal Program that was established to provide cross-country skilled-worker mobility. Red Seal-certified journeypeople are recognized in every province, making it easier for workers to move to areas where they are needed. More than 549,000 certifications have been issued by the program since its inception.

Financial incentives are in place to boost participation. Lisa King, media relations spokesperson for HRSDC, said, "We provide grants to encourage apprenticeships. The Apprenticeship Incentive Grant (AIG) is a $1,000 taxable cash grant for apprentices who complete their first and/or second level of their apprenticeship program with a maximum of $2,000. The Apprenticeship Completion Grant (ACG) is a $2,000 taxable cash grant for eligible apprentices who successfully complete the training and receive journeyperson certification." To date the government of Canada has provided over $426 million in apprenticeship grants.

Related government programs include the Apprenticeship Job Creation Tax Credit to assist employers in hiring Red Seal apprentices and the Tradesperson's Tool Deduction to help employed tradepersons cover the cost of new tools.

The Canadian Council of Directors of Apprenticeship (CCDA) is three years into the Strengthening the Red Seal initiative, which is tasked with enhancing skills assessment and conducting a feasibility study to investigate the opportunities and barriers that exist in each jurisdiction that could affect the delivery of the enhanced standards.

The Take Back Manufacturing initiative is working with industry members to develop an Integrated Career Path to attract high school students to manufacturing careers. Image courtesy of SME Toronto.

Dangling the Carrot

Karin Lindner, industry advocate, founder and owner of Karico Solutions, and author of How Can We Make Manufacturing Sexy? takes the podium around the globe to encourage industry factions to change attitudes toward industry by communicating with the general populous.

"We haven't done a good job selling manufacturing as providing high-profile jobs," Lindner said. "Most parents and children don't understand that they can earn $100,000 a year in industry. So they send their children off to university and they graduate and cannot find jobs."

Money, however, is not the only carrot that needs to be dangled. "We have to question why we want to attract youth to the industry, aside from just filling the jobs," Lindner said. "We need to communicate that creativity is important. Kids today want to be creative and have opportunities to make a difference. In the future we will see Bachelor of Arts going into manufacturing because the creativity will be more and more important."

This communication can begin, Lindner said, by fully utilizing abilities of the current workforce, which can lead to happier, more productive employees who, in turn, will become advocates of the trades. "Show a sincere interest in their talents and skills. Provide education to make them better and tap into the brain power and creativity of the people in our workforce. Their work will become more fulfilling and they will show a different energy, spirit, and attitude."

Lindner also puts some of the onus of training on employees and suggests that the employers and employees share responsibilities. "Employees must take responsibility and do their part. For example, companies should ensure that their employees have the opportunity to continue their education, encourage it, and share the cost burden. That way, employees are also held accountable."

Money spent on training, whether it's for the current workforce or people coming into manufacturing, isn't a cost, Lindner said. "It is an investment in the infrastructure of productivity."

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI