Associate Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

How to develop a strong ERP strategy

Having an ERP strategy will make the implementation process a smooth one

- By Lindsay Luminoso

- February 10, 2020

- Article

- Automation and Software

When a shop decides that it needs to introduce enterprise resource planning (ERP) software into its operations, the decision is usually driven by a pain point or a company vision that cannot be achieved with the current infrastructure. The software is a tool to help solve current challenges and open up the doors to new opportunity. It’s certainly not something taken lightly. Finding the right ERP software for a shop’s specific needs starts with asking the right questions.

"The first step, before anything else, is for a shop to determine its vision," said Nick Knight, senior director of customer services at Global Shop Solutions, The Woodlands, Texas. "A company needs to ask itself, Where are we currently, and what do we want our future to look like? After investigating these two areas, a shop will have the insight into why and how an ERP system should be used within the business."

This is where an ERP strategy comes into place. This strategy is an action plan that will essentially guide the ways in which the ERP software will be put into place within a shop and outlines its daily use.

THREE IMPORTANT FACTORS

People. Shop workers’ active participation and enthusiasm to use the software will make adoption and onboarding that much easier.

"The same questions have to be asked: What do you want to accomplish out of an ERP system?" said Knight. "Where and what do you struggle with today? And that question can be asked, especially of a smaller machine shop, to all employees, as many typically wear multiple hats. It’s just easier to get questions answered and to lay the framework that ERP is a company project."

Getting employees involved in the process early on will help give them a sense of ownership, making it easier to implement process changes down the line. It may also give management insight into overlooked areas of work flow that could be improved. Developing an ERP task force of employees that will take on key responsibilities to learn and train others will enable a smooth transition.

Knight cautions that shops need to look at ERP software as a business tool, not an IT tool. Many companies are quick to pass their ERP strategy to their IT department. However, there is a big difference in how it will be handled and the impact it will have on the business. For this reason, it is important to assess who are the right people to be involved in the process. It may include members of the IT department, but the task force should comprise a number of people from different departments to help management with the overall business vision and gain insight into the type of software a shop needs.

Software. Finding the right software that fits a shop’s specific needs is essential for success.

"Generally, the demand for ERP is born out of some sort of pain," said Steve Bieszczat, chief marketing officer, IQMS, Paso Robles, Calif. "Whether it’s disorganization or wanting to centralize, an ERP system can help organize various areas of a company’s business. Depending on who is involved, a shop needs to go through the basics of operating a business and decide and judge which areas of the business that may not be working as efficiently as they could be."

Bieszczat outlines six major areas of concern for a shop:

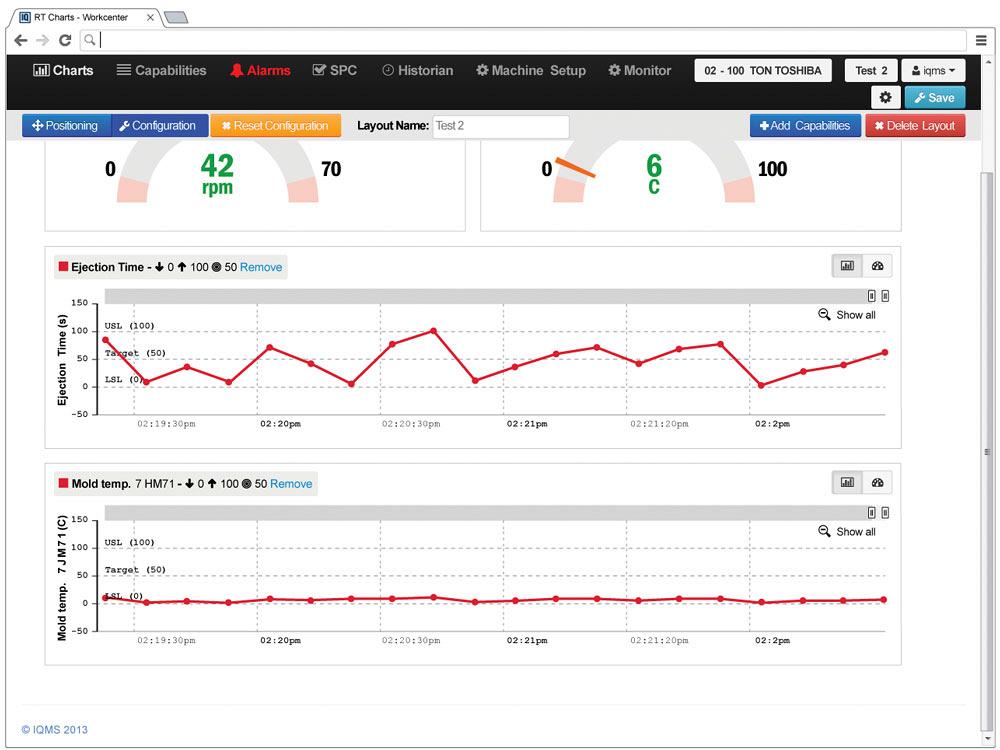

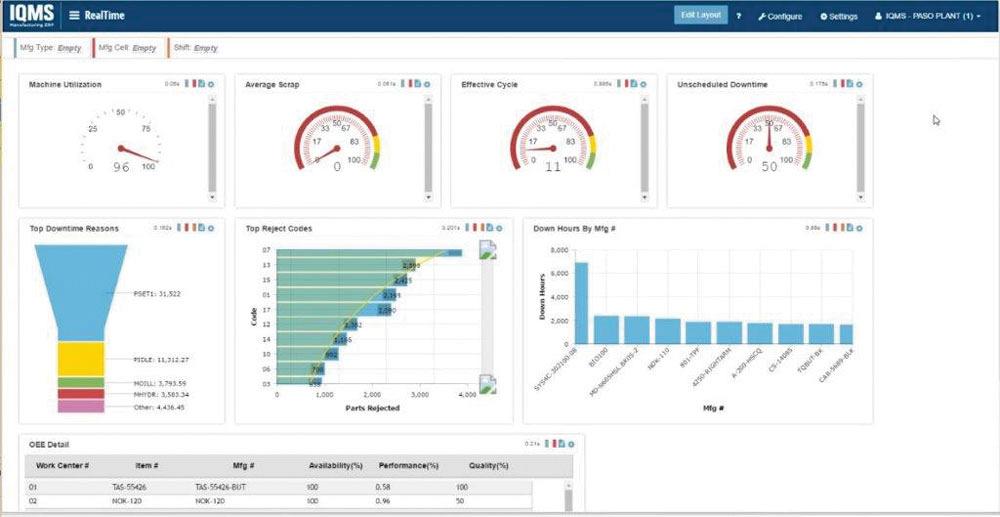

An ERP system is designed for reporting and visibility. If everybody does their part to keep it up-to-date, the system will work well. Photo courtesy of IQMS.

- Accounts Receivable. This is generally the first place where a shop should look. A shop’s goal is to make money, and if accounts receivable is not collecting payment properly or there is little in the way of tracking which customers owe money, this can be a significant pain point.

- Inventory Control. A company may feel that it has way too much inventory that is not being used. Too much money is tied up in inventory. A shop needs to be able to evaluate its inventory from a cost and utilization perspective.

- Production Costing. Being able to quote projects accurately for customers is a good business practice from both a financial perspective and a customer service perspective. The ability to estimate and keep track of production costs will help a shop gain insight into future profitability.

- Scheduling. A disorganized shop may have challenges with prioritizing and scheduling projects, as well as ensuring that there are enough workers on the shop floor to complete the projects on time. The ability to estimate how long it’s going to take for a project to be completed and feeding those estimates into a schedule will act as a production guide for any shop.

- Quality Control. If a shop is constantly getting its projects rejected and returned or customers complain, it could be a sign of poor quality control. Having a system in place that monitors inspection will help prevent shipping bad parts and identify areas of the manufacturing process that could be weak when it comes to quality control.

- Customer Service. When a customer calls a shop to inquire about the status of a project, the last thing the customer wants to hear the shop say is "I’m not sure, I’ll call you back." Without a centralized system, a shop may scramble to find information about the status of a project. Being able to answer questions about the project, shipping, or billing will help improve customer relations and may help gain repeat business.

Once a shop examines these areas of the business, it will then have a better idea of the type of ERP software it will need based on the budgetary constraints and a realistic vision of how it can help. Most ERP software available offers a wide range of tools and features to help a business thrive.

Process. Determining a process that minimizes work flow interruptions and allows for a smooth implementation will make it easier for all involved.

"It’s important not to get overwhelmed," said Daniel Carranco, director of continuous improvement, Global Shop Solutions. "Be self-aware and do not try to accomplish every single feature for every single aspect of the business all on day 1. Starting with the basic elements, day-to-day business processes will all sync together nicely and will reinforce certain processes. However, if a shop tries to it do all at once, they may find themselves months into the process with little to show for it because they have become overwhelmed."

This is why the first two steps are so significant. Having the right people involved in the process, championing the software, will help get others familiarized and on board. It’s also helpful to have a hierarchy of priorities to best learn the software.

A comprehensive implementation process should be developed by the shop’s ERP task force and the software vendor. At first, management will work with the vendor to go through various business cases where the software will be used. Once they accept the configuration and demonstrate its success within the company’s framework, the vendor can set out a training and education agenda to give the shop workers time to learn and practice the software and understand how it will work within the shop’s manufacturing process.

"A shop should certainly have multiple pilot or test runs before the ERP system goes live," said Carranco. "Users can familiarize themselves with the features and sign off that they now know how to perform their job competently in the new system."

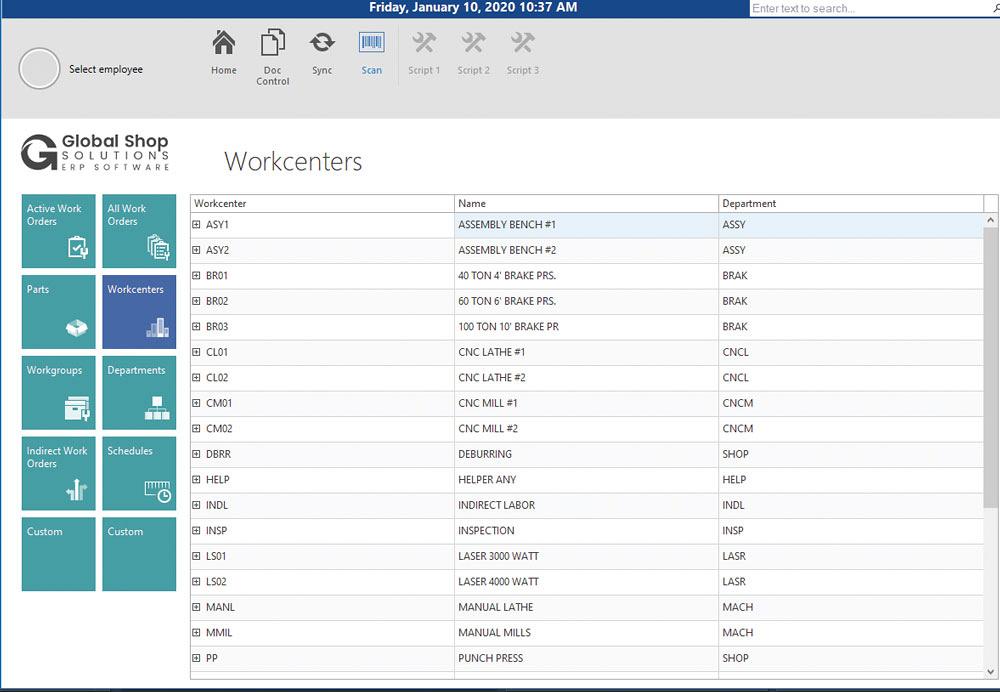

One of the biggest struggles with implementing an ERP system into a shop is challenging a company’s culture. Change is never easy, especially if certain processes have always worked a certain way. There is a change factor that shops need to prepare themselves for when integrating an ERP system. It’s about making sure that, from a process perspective, everybody’s ready to handle the data and output on the shop floor.

The system is only as good as the people using it. An ERP system is designed for reporting and visibility. If everybody does their part to keep it up-to-date, then the system will work well.

"It’s about discipline," said Bieszczat. "For example, if a purchasing agent sees in the system that more steel is needed and orders it, but the person at the receiving dock doesn’t enter the stock received into the system, this can have significant ramifications. It can cause overstock of inventory when the purchasing agent repurchases it thinking stock is low again. It can also cause cash flow issues with so much money being spent on overstock. Users have to respect the system and be disciplined enough to enter the necessary information to allow the software to work for the shop."

Developing an ERP strategy with clearly defined roles and responsibilities is a good start. Defining the pain points and areas of improvement will help keep a company focused on strategic implementation. It’s also important to outline a set of objectives and milestones that will help keep the implementation on track throughout the process.

Shop workers’ active participation and enthusiasm to use the software will make adoption and onboarding that much easier. Data collection keeps shop workers on task and provides managers with data in real time. Photo courtesy of Global Shop Solutions.

Associate Editor Lindsay Luminoso can be reached at lluminoso@canadianmetalworking.com.

IQMS, www.iqms.com

Global Shop Solutions, www.globalshopsolutions.com

About the Author

Lindsay Luminoso

1154 Warden Avenue

Toronto, M1R 0A1 Canada

Lindsay Luminoso, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI