Associate Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Integrating AI in CAD/CAM

True machine learning and AI create faster, easier, better designs

- By Lindsay Luminoso

- September 28, 2020

- Article

- Automation and Software

Machine learning and artificial intelligence (AI) are often thrown around as the latest and greatest buzzwords. But there is often confusion about what exactly these concepts offer, particularly to the manufacturing environment. AI and machine learning go beyond simple programming intelligence and rule-following and require significant data collection to learn and anticipate future moves. In CAD, true machine learning and AI can help designers create faster, easier, and better designs.

However, this is not an instant process. Much like Amazon’s Alexa or Google Assistant, commands are learned over time, and each system improves as it collects user data.

"Right now it’s really a chicken and the egg scenario," said Mark Rushton, senior product portfolio manager, SolidWorks, Dassault Systèmes. "If machine learning-powered assistance is not immediately useful, users may not use it, but in doing that, the program may never be able to improve on the prediction to become useful. We introduced machine learning algorithms into our cloud-based software with the goal of assisting the user in the kind of mundane tasks that are very repetitive. We are working every day to make it as easy as possible for people to use, but it is a process to do it right and add significant value."

AI in CAD

Although AI in CAD is still in the early stages of development, the key focus is to enable the software to optimize the process through intelligent design, making it easier for engineers to create designs that are both efficient and economical.

"The way we help the user out is through the ‘design assistant,’ and it helps by predicting what the user is likely to do next," said Rushton. "When a user has to make selections, if he or she applies a radius or chamfer to a sharp edge, once the first edge is selected, a pop-up will suggest that the design assistant take over and incorporate the radius or chamfer on other edges. It predicts the designer’s next move and then designs accordingly."

Today’s AI in CAD is advancing beyond the typically geometry-based selection and can look at length, direction, and similar features throughout the 3D geometry and make intelligent suggestions. Rather than having the designer add all the elements, a design assistant can prompt the user to apply all intelligent design features, essentially automating the design process.

The more a designer works with the assistant, the more refined and intuitive it will become. Predictions will become more intelligent based on data collected from the designer’s choices.

"For example, if the user creates a chamfered edge and the assistant predicts 50 different edges to incorporate, but then makes another selection, the assistant might then only predict 20 options," said Rushton. "It’s constantly refining the selection based on user commands. It predicts what the user is likely to do. At the moment we are really seeing productivity gains, but we also anticipate seeing gains in the assembly environment."

Rushton noted that one area that is particularly time-consuming is when designers need to bring two parts together in CAD, because the user has to line everything up and remove all degrees of freedom. AI can actually look at the geometry and at how things have been connected in the past and how the individual parts have been connected to other parts in the past and learn from that. An assistant can prompt the user to add features or design in a specific way.

"It’s really about automating the design process," said Rushton. "We want to build on this level of productivity and start with easy projects and build on that."

When a user makes a selection in a CAD model, the assistant may suggest a range of other selections based on the size, shape, and orientation of the geometry. With each selection, the prediction becomes more intelligent and more relevant. Photo courtesy of Dassault.

This will be particularly helpful when it comes to new or junior engineers who may not have the vast design experience of engineers who have been in the field for years. AI in CAD offers the ability to go over the design and prompt for changes to improve manufacturability. Beyond this, there are many areas where machine learning can be applied going forward.

"There is a huge opportunity for machine learning in simulation and manufacturing," said Rushton. "Simulations are very closely tied to design. But there are a number of challenges with simulation right now, especially with determining the best setup. Machine learning can interpret the results and help offer users suggestions on how to create a satisfactory setup for future projects."

Using AI to run a simulation-type test in the background can help the user make better decisions when it comes to materials, geometry, and the process. If the design assistant determines that a cheaper material can be used in place of something else with the same desired result, then the user can select it. This will help create more economical and functional designs.

Today’s AI in CAD is advancing beyond the typically geometry-based selection and can look at length, direction, and similar features throughout the 3D geometry and make intelligent suggestions.

"CAD is so flexible, but one of the challenges is that when it comes to design, there is really no right or wrong way to do something," said Rushton. "Because of this, predicting what a user is going to do next can be challenging. Each designer can make different choices when it comes to design, so that prediction is subjective. That’s why the more data the system can collect, the better the predictions. It’s also not meant to replace the designer, as we are still very far off from replacing human creativity. Machine learning doesn’t necessarily think outside the box for a lot of things."

AI in CAM

The manufacturing environment is changing to meet the demands of customers. Companies are required to build projects faster and cheaper. Ideas are also coming to market quicker. AI can be used to reduce the repetitive functions and tasks of CAM users.

"The intelligence of AI can start to understand those repetitive processes and simplify the task that needs to be done," said Michael Buchli, senior SolidWorks product and portfolio manager, Dassault Systèmes. "This is not necessarily to replace people, but to free up someone’s time to work on the next big idea or fine-tune that little piece of automation that gives their company the edge over its competition."

In traditional CAM, someone takes a part and puts the toolpath on it. The programmer does a lot of the toolpath on it. The programmer does a lot of calculating and decision-making in his head to communicate to the CAM system that something specific needs to happen.

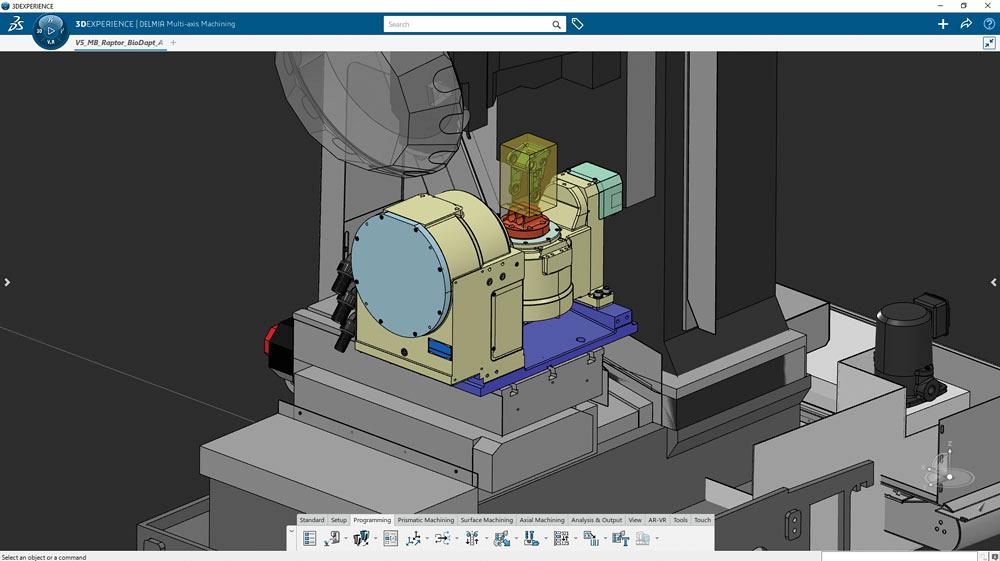

"When you start looking at more complex, high-end CAM systems, they are starting to incorporate AI and machine learning where the programmer can simply drop in the machine cell and snap the part where we want it to go and it will create a virtual twin that actually represents what’s going to happen on the shop floor."

Through the use of AI in CAM, if the software knows what specific machine, settings, and capabilities are used continually, it can offer a better and more well-rounded picture of the real-world manufacturing process. From there it can simplify the CAM process by insightfully suggesting better, more efficient toolpaths and fixturing options.

Through the use of AI in CAM, if the software knows what specific machine, settings, and capabilities are used continually, it can offer a better and more well-rounded picture of the real-world manufacturing process. Photo courtesy of Dassault.

The goal of AI in CAM is to simplify and streamline repetitive tasks to make them quicker. On the output side, companies will start using AI more with robotics and automation on the shop floor.

One of the big challenges with AI in CAM is the shift in mindset that is needed to really take advantage of the technology. Workers are often accustomed to a work flow and a process and not necessarily comfortable making significant changes.

The goal of AI in CAM is to simplify and streamline repetitive tasks to make them quicker.

"However, because things move so fast today, incorporating intellectual processes that can create the intellectual knowledge that makes a process more successful can help free up a shop to move on to the next big thing," said Buchli. "For companies to fully take advantage of AI, managers and employees need to get familiar and on-board with the process. AI allows shops to develop standard practices and shift focus to not always maintaining these processes, but to look ahead."

Similar to AI in CAD, if done correctly, AI in CAM will become the native way of working. If, as a user programs, the AI is able to pick up the work flow and process, over time it will predict what machine, fixtures, tools, and toolpaths are needed. It learns what a user is doing as he is doing it to reduce steps for similar processes in the future.

Associate Editor Lindsay Luminoso can be reached at lluminoso@canadianmetalworking.com.

Dassault Systèmes, www.3ds.com

About the Author

Lindsay Luminoso

1154 Warden Avenue

Toronto, M1R 0A1 Canada

Lindsay Luminoso, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada

DiPaolo Machine Tools Open House 2024

- June 4 - 5, 2024

- Mississauga, ON Canada

FABTECH Canada

- June 11 - 13, 2024

- Toronto, ON Canada

Zoller Open House & Technology Days 2024

- June 12 - 13, 2024

- Ann Arbor, MI