- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Coping with COVID-19

Job shops adjust to the pandemic to limit exposure

- By Nate Hendley

- June 19, 2020

- Article

- Health & Safety

A worker at Ellery Manufacturing, Surrey, B.C., disinfects a control panel as part of the company’s efforts to combat COVID-19. Photo courtesy of Ellery Manufacturing.

Sanitizing, social distancing, and many other health and safety measures are now part of daily life at Canadian job shops. While most shops remain open (provincial pandemic guidelines generally view manufacturing as an essential service), it’s far from business as usual.

COVID-19 has diminished workloads, complicated sales and supply chains, and forced some owners to contemplate government assistance and layoffs.

Job shop owners mainly have taken a safety-first approach, implementing procedures to keep employees healthy and machinery running.

“We took action as soon as we realized that COVID-19 had the potential to seriously harm our employees and possibly hurt our ability to operate,” said Paul Ellery, president of Ellery Manufacturing in Surrey, B.C.

According to Ellery, these actions included:

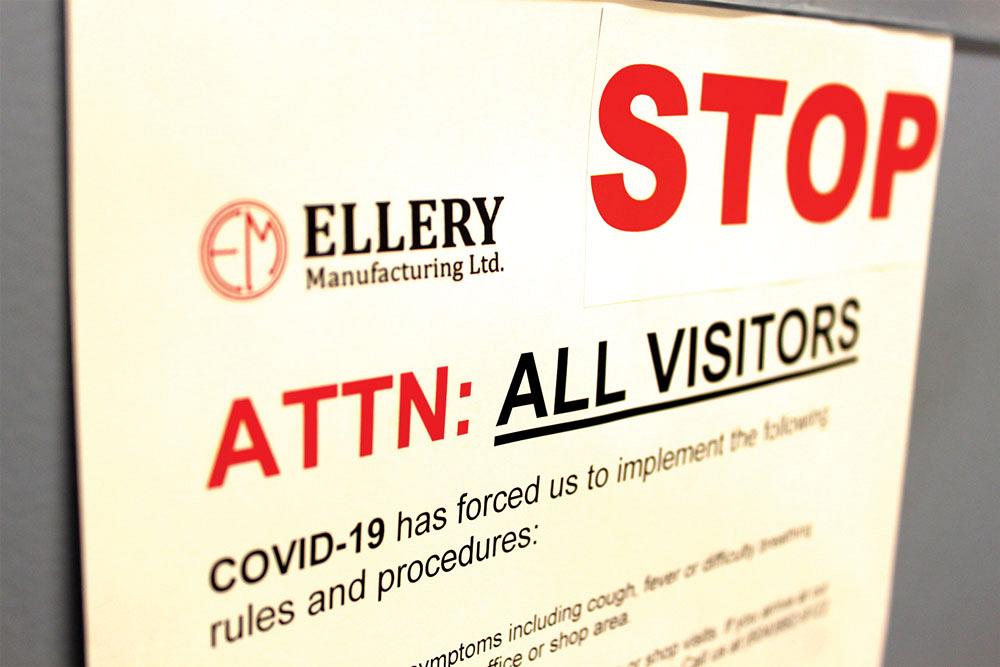

- Posting notices in high-traffic areas reminding employees of the safety measures needed to reduce the chances of infection and the steps to be taken if an employee feels they might be infected.

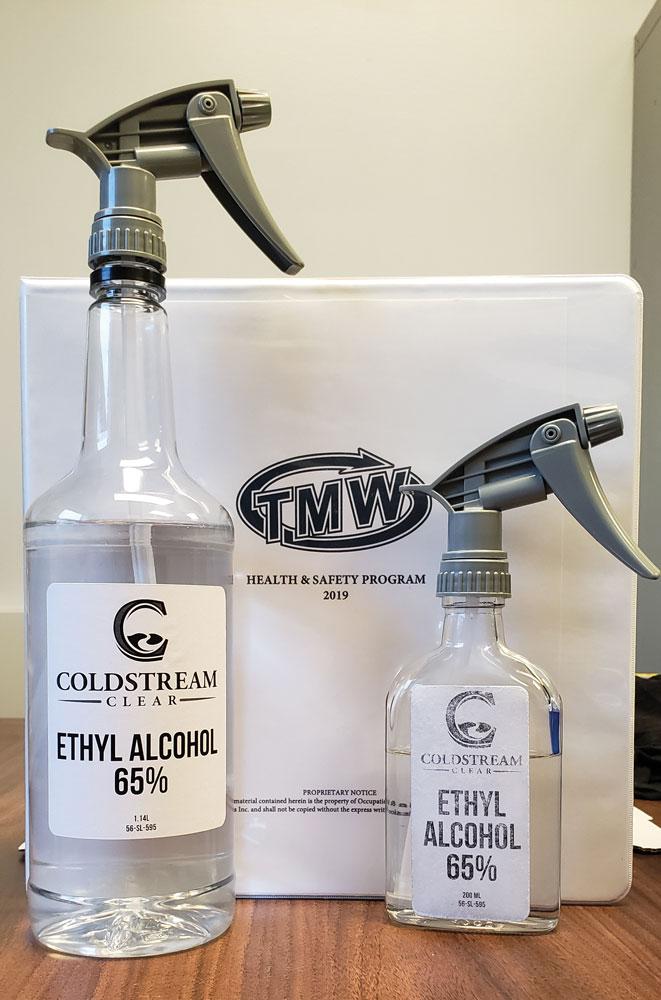

- Daily cleaning and disinfecting of regularly touched surfaces in the offices, shop floor, and employee areas. In addition, the supplying of bottles of hand sanitizer throughout the shop floor, employee spaces, and administrative offices.

- Restricting non-essential visitors from accessing offices and production facilities. Pre-approved service providers must always keep visits brief and wear masks and gloves.

- Providing employees with masks and gloves when available.

- Having non-production-related employees work remotely.

Ellery Manufacturing has a dozen employees, about 16 machine tools (mostly mills and turning centres), cranes, welding equipment, and 20,000 sq. ft. of production and storage space. Machine tools and other gear already were positioned far apart on the shop floor so, according to Ellery, social distancing hasn’t been a problem. Anytime workers need to get closer than 2 m from each other, they are required to wear face masks.

“We’re quite spread out throughout the facility so there’s no issue with social distancing other than when we’re conferring on a project,” explained Ellery.

Similar measures have been taken at other job shops across the country.

Paul Chissell, president of Wynn Machine & Manufacturing, Edmonton, has enhanced washdown procedures, provided hand sanitizer, and made face masks available for staff.

“We’re fortunate because our machines are kind of spread out a bit, so nobody’s working on top of each other. We changed our lunchroom a bit and spread people out there. Just have been following the basic recommendations we’ve been getting from Health Canada,” said Chissell.

COVID-19 has caused manufacturers to limit access to their shops and offices. Photo courtesy of Ellery Manufacturing.

Health Canada guidelines also are front and centre at Nova Scotia shops Velocity Machining & Welding in Dartmouth and Techtronics Machine Works in Musquodoboit Harbour.

“Both companies are following government guidelines. Employees have been made aware of the physical distancing requirements, and bottles of hand sanitizer have been provided throughout our shops,” said Sean MacPhee, president of Velocity and Techtronics.

Limiting Travel Limits Risk

In addition to introducing sanitizer and masks, Larry Stuyt, president/owner of Ontario Laser Cutting in Tillsonburg, Ont., has given employees the option of staying at home. So far no one has taken up the offer. Staff who come to work have been asked to limit travel to places that might expose them to COVID-19 when they finish their shifts.

Stuyt said he doesn’t want employees “to bring the virus into work with them the next day. A family is only safe when it stays together, but if one member decides to travel around and then come home [with the virus,] then the family is not safe anymore. As a company working together each day, we are like a family.”

While such measures might help staff from falling ill, COVID-19 has impacted job shops in other ways.

“Work has diminished significantly. Suppliers and customers alike have shut down,” said Gerry Addley, president/owner of Addley Precision in Midland, Ont.

Addley, who has introduced hand sanitizing stations and other health initiatives, estimated his workload has decreased by 50 to 75 per cent because of the pandemic.

MacPhee said his companies have not lost work specifically because of the outbreak, but noted that the workload has definitely lightened.

Some shops, however, report a very different situation.

Ontario Laser Cutting counts the medical industry as a major client.

Hand sanitizing now is part of daily life for manufacturing workers. Photo courtesy of Ellery Manufacturing

“We have been busy during these last few weeks. There have been no cancellations of any projects. We supply material for bed frames, covers, and some smaller [medical] components,” said Stuyt.

“Thankfully, our ability to operate has not been hampered by COVID-19. Most of our employees are working. We haven’t had to turn away any work, and active jobs have been progressing on schedule. While no existing orders have been cancelled, we have unfortunately had some projects temporarily put on hold by customers who are dealing with their own challenges and industry-related issues (the oil and gas slowdown),” said Ellery.

Government Assists Workers, Businesses

The federal government has launched several programs to assist businesses and workers alike.

Employees who have lost income because of COVID-19 can apply for the Canada Emergency Response Benefit (CERB) and receive a $2,000 taxable monthly subsidy for up to four months. Hard-hit companies can apply for the Canada Emergency Wage Subsidy (CEWS), which covers three-quarters of a worker’s wage, up to a maximum of $847 a week, for three months.

Small businesses might be eligible for interest-free loans up to $40,000 via the Canada Emergency Business Account (CEBA) initiative. Incomes taxes and HST/GST payments all have been deferred, and some provinces have introduced financial supports of their own.

Facing diminished workloads and the spectre of infection, shop owners have had to consider laying off employees.

“We had one employee who was required to stay home for 14 days as a precautionary measure because they exhibited possible virus symptoms, but we have not been forced to lay off any employees due to slowdowns in work specifically because of COVID-19,” said Ellery.

“Velocity has laid off one part-time staff member,” said MacPhee.

Some staff at Wynn Machine volunteered to be temporarily laid off because “they either had people at home who were high-risk or were taking care of parents,” said Chissell.

He added that he is interested in the wage subsidy.

Masks and gloves are worn while working to help stop the spread of COVID-19. Photo courtesy Wynn Machine & Manufacturing.

“I think that is really going to help smaller businesses. We’re just getting the details of that now. I know it’s only a 12-week program, but I think that will help us retain our staff,” he said.

He also applied for a loan through the CEBA program, as well. The latter initiative “will definitely help out a lot of the smaller businesses that are having trouble with day-to-day expenses,” added Chissell.

That said, some job shoppers say they don’t need financial relief—for now at least.

“We’ve done our research and are aware of the support programs, but thankfully our business hasn’t been in a position where we would require assistance. That said, if the COVID-19 lockdowns continue for an extended period, we will likely be forced to apply for short-term government assistance,” said Ellery.

Ellery Manufacturing does work for the oil and gas sector, which is currently experiencing extreme price volatility. This volatility has been caused by oversupply and sinking demand, the latter a result of government-mandated economic shutdowns designed to prevent the spread of COVID-19. The situation is particularly dire in Alberta, where many job shops rely heavily on contracts from the oil industry.

“We’ve got this perfect storm where everything is driving against us. In Alberta, it’s really going to hurt the job shops,” said Chissell.

At its peak a few years ago when oil fetched a higher price, Wynn Machine had 23 employees. Today the company is down to less than half that number. Since early April the remaining employees have been working on a reduced schedule because of both COVID-19 and the collapsing fossil fuel prices.

“Most of our guys are now doing 24, maybe 30 hours a week, depending on their workloads,” said Chissell.

Chissell has also been holding off on buying new equipment to replace or complement his existing turning centres and other machines.

“Our last major machinery [purchase] was in 2015. Usually we would buy something every year. For job shops, you must keep technology going, but our machines are not getting big hours so they’re not wearing out. We’re trying to make them last,” he said.

Hand sanitizer have been provided throughout the shop at Techtronics Machine Works in Musquodoboit Harbour, N.S. Photo courtesy of Techtronics Machine Works.

Retooling Not for Everyone

While some manufacturers have retooled to produce ventilators, face masks, hand sanitizer dispensers, and other products, most job shops say this isn’t a realistic option for them.

“We have been approached by the government, but the reality is that our shop isn’t equipped to produce ventilators or PPE [personal protective equipment]. Our production capabilities are geared toward short-run, medium- to large-industrial-part, custom machining. Our facilities and equipment simply aren’t designed to produce the types of items currently required to address COVID-19,” said Ellery.

In Nova Scotia, MacPhee said that his company has been contacted by multiple customers with regards to making new COVID-19-related items, but because of the requirements of Health Canada, Velocity was unable to produce the products they wanted.

“It’s not that the requirements were too strict. Applying for approval for a single product that we had no interest in making just did not make sense, especially since we knew there would be issues sourcing the materials required to make the product,” said MacPhee.

However, Velocity was already making health-related face shield components for a medical company that was certified by Health Canada before the outbreak. No retooling was necessary because the shop is very flexible, said MacPhee.

Supply Chain Disruption

Not surprisingly, dealing with suppliers and customers has become increasingly difficult.

“It’s absolutely insane! You can’t get anything done. Getting raw materials for everyday stuff is more and more difficult all the time,” said Addley.

“Suppliers are very limited with product as well as service. Everything takes twice as long to get. We have cut all customers off from picking up [products and parts] and do limited delivery ourselves,” said Stuyt.

“When it comes to our vendors, access to production materials, tooling, and shop supplies hasn’t been an issue. We’ve put some strict COVID-19 safety requirements in place for any outside service suppliers that require access to our facilities, but, overall, the rules have been followed, service levels have been good, and we’ve had no issues,” said Ellery.

“Velocity’s customers include regional governments, fire and police services, emergency health services, and electrical utilities. Many of these customers provide essential services and it is therefore essential that Velocity continues to provide the services that they require. For that to happen, we do have to meet in person with some customers. However, as much as possible we are limiting our staff’s interaction with customers,” said MacPhee.

Workers at Edmonton’s Wynn Machine & Manufacturing wear masks, especially when working in close proximity to each other. Photo courtesy of Wynn Machine & Manufacturing.

As for suppliers, “some of them now wear a mask when they come to replenish our automated vending machines and all are maintaining physical distancing,” added MacPhee.

While some job shop owners describe COVID-19 as the biggest challenge they’ve ever faced, others point to previous trials they’ve endured. These include the economic downturn of 2008-09, tariffs, free-trade squabbles, and up-and-down oil prices.

“We’ll make it. We’ve been through storms before. Hopefully, we get some good news in the next few months,” said Chissell.

Contributing writer Nate Hendley can be reached at nhendley@yahoo.ca.

Addley Precision, www.addleyprecision.com

Ellery Manufacturing, www.ellerymfg.com

Ontario Laser Cutting, www.ontariolasercutting.com

Techtronics Machine Works, www.tmwltd.ca

Velocity Machining & Welding, www.velocitymachining.ca

Wynn Machine & Manufacturing, www.wynnmachine.com

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Identifying the hallmarks of a modern CNC

CTMA launches another round of Career-Ready program

Collet chuck provides accuracy in small diameter cutting

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI