Associate Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Large-diameter parting off

A look at what operators need to consider when parting off large-diameter components

- By Lindsay Luminoso

- May 13, 2019

- Article

- Cutting Tools

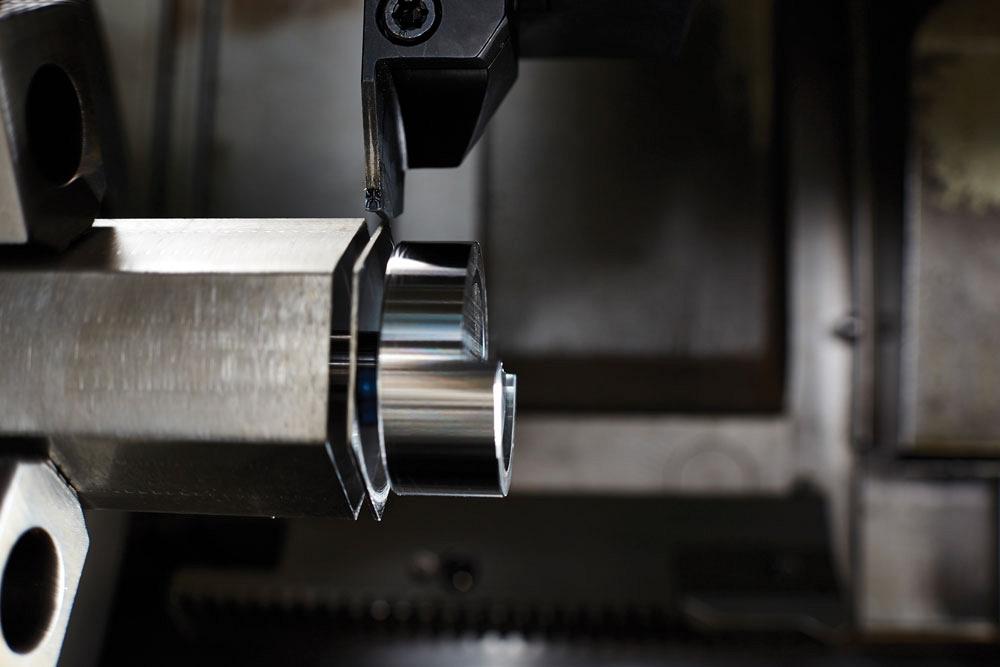

Tungaloy’s EasyMulti-Cut insert increases tool life with a unique plug-in self-clamping system and chip control and evacuation. Photo courtesy of Tungaloy.

Parting-off operations tend to be only a small part of a component’s total machining time. And as one of the final operations performed on a part, it is essential to maintain proper procedures to ensure finish-quality parts.

Shops looking to part off components with large diameters have some additional considerations they need to be aware of that go beyond standard parting-off operations.

INSERT SELECTION

Proper insert selection is essential to quality parting-off operations, especially when it comes to large diameters. Cutting tool manufacturers define “large diameter” differently, and it can range from 4 in. up to 7 in. However, any part with a 1.5-in. diameter or larger requires additional considerations when it comes to parting-off operations, explained Mark Filosemi, senior global product manager, grooving and cut-off, Kennametal, Pittsburgh, Pa.

Regardless of part diameter, one general rule should be followed when choosing an insert width: The length of cut should not exceed eight times the width of the insert.

“It’s just a rule of thumb that is standard in the industry,” said Raymon Avery, prod-uct manager—turning products, Ingersoll Cutting Tools, Rockford, Ill. “Some people don’t know it and not everyone follows it. But on the cutting tools side, we try not to exceed this insert width rule.”

Filosemi added that it’s important to work with the largest insert possible for the diameter to ensure proper cutting and productivity. However, a bit of a balance needs to be struck when choosing an insert. Most shops are looking to save material or improve material usage. Choosing a narrow insert would result in bar material savings, but a narrow tool is not always optimized for the cutting forces needed for a large-diameter part.

“Shops need to balance the economy with the productivity when it comes to choosing the right insert,” said Filosemi. “We’d like to stay with neutral-style inserts, which help with chip control, as opposed to lead angle inserts. Although when used to help reduce cutting forces in standard parting applications, lead angle inserts increase chatter and reduce stability in large-diameter parting. Applying neutral inserts creates a more stable cutting zone between the insert and the workpiece.”

CHIP EVACUATION

For parting-off operations, chip evacuation can be a significant challenge. The tool is often deep inside the part, making it hard for the chips to be expelled, especially because in many cases the chips are the same width as the cut being produced.

“If the chip is to jam up in the groove,” said John Mitchell, general manager, Tungaloy Canada, Brantford, Ont., “this could have catastrophic consequences. Therefore, chip formation and evacuation are critical in part-off applications. In order to effectively evacuate the chip from the groove, the chip produced should be a narrower width than the slot.”

According to Mitchell, an effective chipbreaker should be designed to form the width of the chip into a U shape, thereby making the chip narrower than the groove opening. Of course, if the U-shaped chip runs off the cutting edge as a continuous ribbon formation, there is still a high probability of chip jamming and catastrophic failure. Therefore, the chipbreaker should not only form the chip in a U formation, but should curl the chip into a “watch-spring” formation, making the chip easy to expel and preventing chip jamming.

Kennametal’s single-side cutoff tool performs multidirectional turning. The Beyond™ Evolution™ Triple-V Seating feature provides functional stability and minimizes vibration. Photo courtesy of Kennametal.

Investing in an effective chipbreaker to prevent this chip packing is one way to avoid this problem.

COOLANT OPTIONS

Coolant can also be an effective tool to help expel chips from the cutting zone. Anytime high-pressure coolant gets down to the cutting edge helps with chip evacuation. For standard cutting operations, flood-type cool-ant is sufficient in removing chips. However, with parting-off operations, specifically on large-diameter parts, this is not always effective.

“Flood coolant is not efficient for deep parting-off operations,” said Filosemi. “The flood can’t quite reach the cutting zone because of the shoulders of the workpiece. Through-the-tool coolant is necessary in this type of application.”

The experts agree that coolant delivery is important for proper chip evacuation. There are many parting-off tools on the market that offer a precision-delivered coolant. It’s not only important to use coolant, but also to get it in the right position. Running a higher coolant pressure, if the machine can support it, will also help operators see cutting advantages.

Filosemi suggested that for parting-off operations, operators would gain the most advantage if they can get coolant pressure to around 70 to 80 bar.

OPERATING GUIDELINES

For parting-off operations, it is important to maintain a centre height of ±0.1 mm (±0.004 in.). Positioning the parting-off tool below centre causes increased nib formation and insert breakage because of unfavourable cutting forces. Also, the workpiece is curling around and coming across only a small cross section of the cutting edge, which can draw the insert out of the pocket instead of allowing it to cut.

“Positioning 0.1 mm above is really to help with the minimal amount of flex a blade will receive from coming in contact with the workpiece bringing it back to centre,” said Filosemi. “Positioning too far above centre reduces the clearance below the cutting edge, causing the front flank of the insert to wear, resulting in a higher chance for rubbing and vibration, creating noisy chatter and insert breakage.”

If the centre height is above or below the ±0.1 mm rule, operators will experience a number of cutting challenges and reduced tool life. Another good operating practice is reduc-ing the feed rate as the tool gets close to centre. This practice can be used for all size components, but is especially important for large-diameter parts.

“We recommend reducing the feed rate by 80 per cent when we get close to that centrepoint,” said Avery. “When the insert cuts to approximately ¼-in. diameter, we’d like to reduce the rate to take some of the pressure off the insert. Lower feed rate at the centre reduces the cutting forces and increases tool life.”

Also, to avoid breakage, the feed can be stopped approximately 0.5 mm (0.02 in.) before reaching the centre of the bar. This will allow the cut-off part to drop due to its weight. This is particularly effective the larger the part diameter.

Kennametal’s Beyond™ Evolution™ coolant delivery directs coolant precisely to the cutting edges underneath the chip. Photo courtesy of Kennametal.

PINCHING EFFECT

Operators should be aware of some operating guidelines when it comes to large-diameter parts, particularly when it comes to pinching.

“When we part off large-diameter components, the insert gets closer to the centre of the bar as the part is getting close to being cut off, and the weight of the diameter is going to automatically collapse or pinch the workpiece onto the cutting tool,” explained Avery. “In situations like this, we like to slow down the speed or feed rate to help avoid this pinching effect. However, there’s really not much more we can do because it is really a weight issue. It’s important to be mindful of this effect and adjust RPM/SFM depend-ing if the pinching is from gravity or centripetal force. In addition, we can make sure a tougher grade of insert is used. This will help absorb the forces that occur from pinching.”

Avery noted that using a sub-spindle is an ideal machine setup for parting-off operations. A machine sub-spindle can be a very expensive option, but it helps stabilize the workpiece by clamping both ends, reducing flex. It also might help increase tool life.

PARTING-OFF TOOLHOLDERS

According to Mitchell, traditional part-off holders fall into two main categories: screw clamping and elastic clamping. The challenge with screw-clamped part-off holders is the screw itself acts as an obstruction to the chip evacuating the groove and can cause chip jamming.

Elastic clamping is another option, but it too has its challenges. Mitchell explained that elastic clamping is the process of using a tool to stretch open the insert mounting area, sliding the insert into position, and releasing the tool that was used to stretch the opening to allow the insert to slide into position. This method removes the problem of the screw obstructing the chip evacuation, but the open and closing by stretching the steel causes the steel used to clamp the insert to fatigue; the tool loses its clamping forces and ultimately causes failure.

Associate Editor Lindsay Luminoso can be reached at lluminoso@canadianmetalworking.com.

Ingersoll Cutting Tools, www.ingersoll-imc.com

Kennametal, www.kennametal.com

Tungaloy Corp., www.tungaloy.com

About the Author

Lindsay Luminoso

1154 Warden Avenue

Toronto, M1R 0A1 Canada

Lindsay Luminoso, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Modest manufacturing growth appears likely

There’s no business like show business

Tighitco, DCM Group Aerospace join forces on Airbus A220 program

Software automatically identifies vulnerable production assets

NAIT names Sandvik Coromant the 2024 Distinguished Industry Partner

- Industry Events

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada

DiPaolo Machine Tools Open House 2024

- June 4 - 5, 2024

- Mississauga, ON Canada

FABTECH Canada

- June 11 - 13, 2024

- Toronto, ON Canada

Zoller Open House & Technology Days 2024

- June 12 - 13, 2024

- Ann Arbor, MI