Technical Advisor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Technology spotlight: Holemaking tools

Familiar tool family now is mastering holemaking

- By Andrei Petrilin

- October 31, 2022

- Article

- Cutting Tools

ISCAR's development of the Multi-Master tool line positively affected the world of cutting tools at the turn of the last century. The three-pronged principle of this family of tools was based on the face contact between a carbide head and tool, centring the head by using a short taper, and securing the head in the tool body using a threaded connection.

The design of the thread, made of hard, brittle carbide, made fast and simple head replacements possible. The threaded connection quickly found its way into numerous tool assembly systems with exchangeable carbide heads, which now is an industry standard.

At first, the line was intended specifically for milling in the die and mold industry. But soon after, the automotive, aerospace, and general machinery industries adopted it in their production processes as well.

While milling remains the line’s focus, it now can be used in drilling applications too.

Drilling Options

The tooling line now has expanded to cover a broad range of applications that includes drilling, countersinking, and chamfering hole edges.

Two types of heads create the tool’s cutting section. The first type is similar in shape to a multi-flute, solid-carbide tool, but differs in overall length and cutting-edge length. Increasing the number of flutes on the cutting head makes cutting more stable and productive.

The first type of heads is produced from ground stepped cylindrical blanks. The second heads are shaped beforehand by pressing and sintering with a minimal oversize. Additional grinding defines the final shape of this head.

The second head has two flutes and is characterized by high strength. This facilitates increased feeds per tooth when compared to the first heads. The pressing technology used to make them also enables the production of diverse, complicated geometric shapes.

The heads are mounted in holders that may be an integral body (shank) or part of an assembly comprising a shank, extension, and reducer. The holder is a rotating solid tool with cylindrical and conical sections without flutes that allow chip evacuation.

The Multi-Master drilling heads are suitable for relatively shallow holes. This may pose a limit in holemaking applications. Yet for short-hole drilling in which the part shape or a workholding fixture requires a high tool overhang, the long reach of these tools is more rigid when compared to a typical fluted drill.

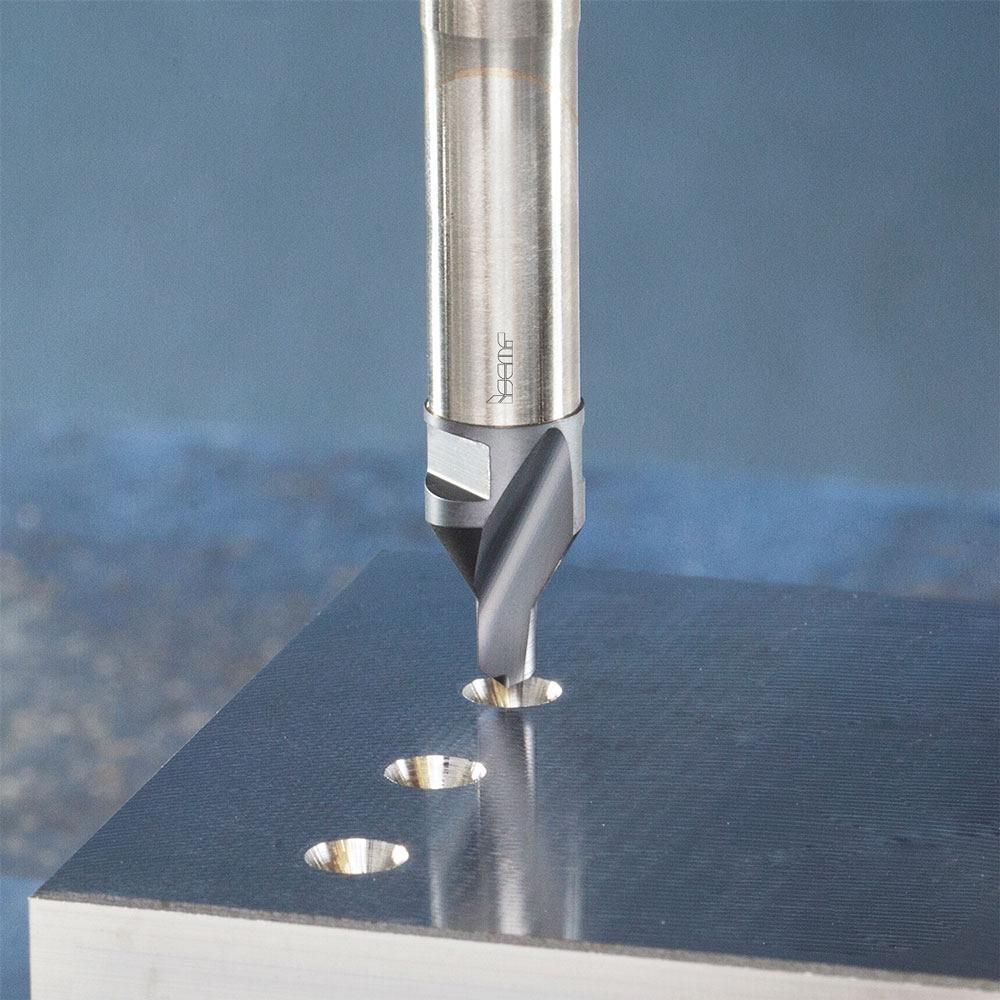

The company’s HCD two-flute heads are made with numerous point angles, including 60, 80, 90, 100, and 120 degrees, which makes them suitable for applications such as centre drilling, spot drilling, hole chamfering, and countersinking. They can create conical holes for countersunk screws, bolts, and rivets according to ISO/DIN/ANSI standards in solid material.

If the workpiece is pre-drilled, countersinking efficiency is improved by using the line’s multi-flute EDF heads that help increase productivity in chamfering operations. When chamfering or deburring the backside of a hole, a double-sided chamfering head is available.

Centre Drilling

Centre drilling is one of the most common holemaking operations. Typical tools that perform this task are called centre drills. In the past, double-sided HSS centre drills were the most commonly used tools for centre drilling. The new line includes centre drilling heads that increase tool life and productivity, even under strenuous cutting conditions.

Spot Drilling

NC spot drills are another type of commonly used tools. Characterized by their small depth of cut (DOC), these tools primarily are used on CNC machines for creating pre-holes that allow precise drilling without using guide bushings.

The new line also includes NC spot drilling heads. A thin web at the head’s point prevents the drill from walking during the machining operations. In heads with a 90-degree point angle, these tools can be used in hole chamfering.

Flat-bottom Hole Creation

Flat-bottom holes are common in many parts. These holes are needed for spring seats, screw head sockets, and washer ports. A simple way to produce these holes is by drilling with flat-bottom drills. If the drilling depth does not exceed 1.2xD, the new line has a two-flute head that can be used. The head also is suitable for drilling holes on slanted surfaces.

Andrei Petrilin is technical manager for ISCAR Tools, 2100 Bristol Circle, Oakville, Ont. L6H 5R3, 905-829-9000, www.iscar.ca.

About the Author

Andrei Petrilin

2100 Bristol Circle

Oakville, L6H 5R3 Canada

905-829-9000

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI