- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Case Study: Metal additive manufacturing install

Calgary’s Exergy Solutions uses metal additive manufacturing system to print parts with high wear resistance and hardness

- September 13, 2021

- Article

- Metalworking

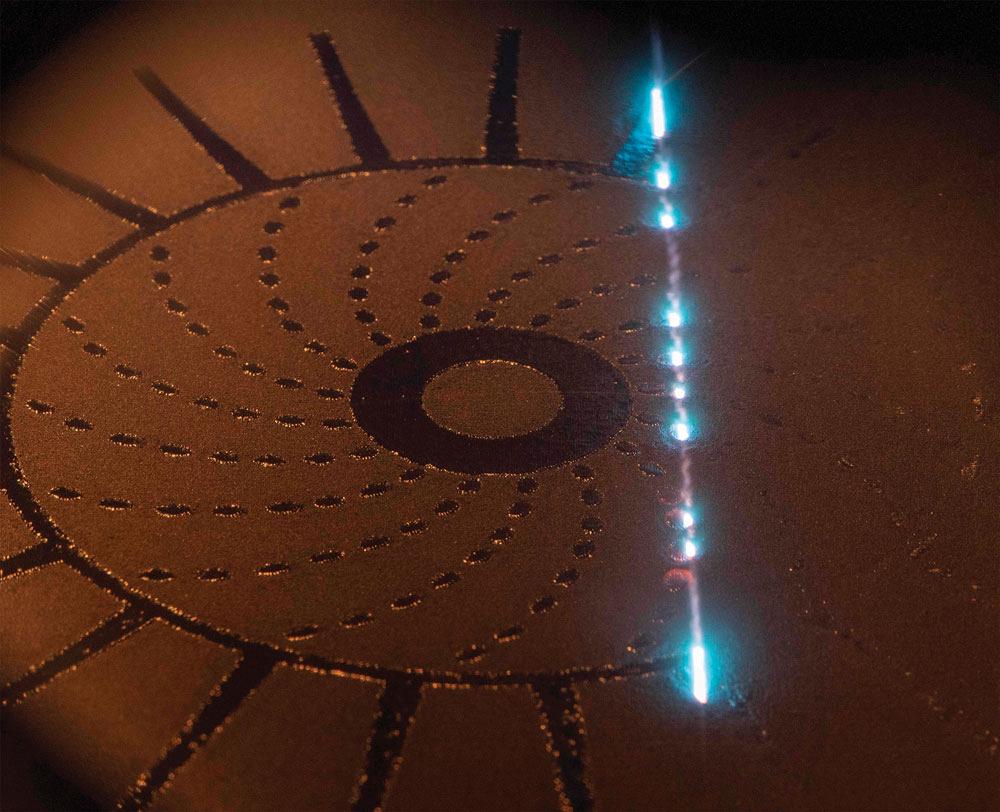

With NeuBeam technology, high temperatures are applied only to the part and not the bed during the AM build.

Exergy Solutions, Calgary, is an engineering consultancy that offers end-to-end, fit-for-purpose, lab-scale, and pilot-scale equipment for research and innovation.

The company has been operating since 2013 and opened its X-Lab in 2019, which offers state-of-the-art industrial additive manufacturing (AM) and post-processing work, as well as a wireless augmented and virtual reality studio. Exergy works with clients in numerous sectors, including the demanding and highly regulated industries such as oil and gas, mining, manufacturing, and R&D.

The company’s purchase of the first Calibur3 AM machine from Wayland Additive, Huddersfield, U.K., was enabled with support from Next Generation Manufacturing Canada (NGen).

“NGen’s mission is to support the development of unique, world-leading manufacturing capabilities in Canada,” said Jayson Myers, CEO, NGen. “It is investments like this that will enable our manufacturers to compete in the global marketplace and deliver the integrated engineering solutions that their customers need.”

New Manufacturing Opportunity

“The investment in Wayland’s technology means that we can present a compelling solution to our customers’ wear challenges,” said Dr. Dave Waldbillig, director of advanced manufacturing at Exergy. “The partnership combines the high wear resistance and toughness of the Vibenite series of materials from VBN Components with the larger build volume and speed of the NeuBeam process and Exergy Solutions’ application engineering support.”

Exergy focuses on developing technology for high-wear environments where complex geometries and large part sizes are needed for applications across many industry sectors such as oil and gas, minerals processing, forestry, agriculture, pulp and paper, and power generation. The new metal AM system supports innovation at the company with its ability to process numerous materials in a large build volume.

The Vibenite series of materials Exergy uses are unique hard and wear-resistant materials for AM, and they allow customers to create large, geometrically complex parts and components that are impossible to produce using traditional production processes.

These Vibenite materials are characterized by high fatigue resistance thanks to their high cleanliness, good wear resistance and hardness because of a high carbide content, and no porosities and full hardness all the way through the component.

“The alliance between Exergy, Wayland, and VBN means that we are able to offer significant customer benefits. With support from VBN, Exergy can now supply full-service design, manufacturing, and qualification support for large parts with complex geometries made from materials that are difficult or impossible to machine. This in turn means longer component lifetimes, with the entire part, not just specific areas of the part, made from highly wear-resistant materials,” said Exergy CEO Billy Rideout.

First Worldwide Sale

“We are extremely pleased with the response to the launch of our Calibur3 machine, and to be able to announce our first sale to Exergy is very exciting. We are in advanced discussions with a number of companies interested in our groundbreaking metal AM process,” said Peter Hansford, director of business development, Wayland Additive.

Exergy Solutions, Calgary, purchased the first Calibur3 AM machine from Wayland Additive, Huddersfield, U.K., thanks to support from Next Generation Manufacturing Canada (NGen).

According to Hansford, the Calibur3 metal AM machine uses what the company calls NeuBeam technology, which he says has eliminated the charging issues that make electron beam melting (EBM) processes unstable.

“NeuBeam is a ‘hot part’ process rather than a ‘hot bed’ process like traditional e-beam processes. This efficiently creates parts that are free of residual stresses because the high temperatures are applied only to the part and not the bed, ensuring free-flowing powder post-build -- no sinter cake -- and stress-free parts with reduced energy consumption,” said Hansford.

NeuBeam is material-agnostic, can produce complex geometries, and typically is 30 to 40 per cent faster because the need to maintain and sinter the cake has been eliminated, states the manufacturer.

Wayland Additive, www.waylandadditive.com

Exergy Solutions, www.exergysolutions.com

VBN Components, www.vbncomponents.com

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

CTMA launches another round of Career-Ready program

Collet chuck provides accuracy in small diameter cutting

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI