Associate Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Manual machines in the modern machine shop

NC Machine & Tool opts for both manual and CNC machines on the shop floor to meet production demands

- By Lindsay Luminoso

- August 16, 2019

- Article

- Metalworking

NC Machine & Tool prides itself on maintaining a state-of-the-art facility with cutting-edge technology and equipment. Based in Winnipeg, this machine shop has been in business for over 40 years with founder Dan Roche and his son Chris at the helm. In those years, the company has grown from a small shop into a 19,000-sq.-ft. facility with equipment ranging from milling machines to grinders and lathes. It has invested in a number of advanced CNC machine tools, but still maintains a number of manual lathes and milling machines on the shop floor to serve its customers better.

"We’ve had pretty steady growth over the last few years, and we have expanded our reach into areas like the food, military, and aerospace industries," said Chris Roche, general manager. "We are constantly find-ing new markets and new customers, but the majority of our business comes from OEM mining equipment we manufacture, as well as producing high-precision tooling."

Chris noted that Winnipeg is a small city and NC Machine has a few competitors, but for the most part, the shop can offer services that sets it apart, such as gear cutting and cylindrical and surface grinding. The shop currently has about 16 employees, many operating more than one piece of equipment to add flexibility depending on the jobs that come in.

MODERNIZING THE SHOP FLOOR

"Every year we seem to be adding more and more equipment," said Chris. "We are also improving on some of the existing equipment. Last year we made a significant investment in our equipment, upwards of $1 million. We are restructuring and trying to reorganize the shop floor to make room and improve process flow of the new machines."

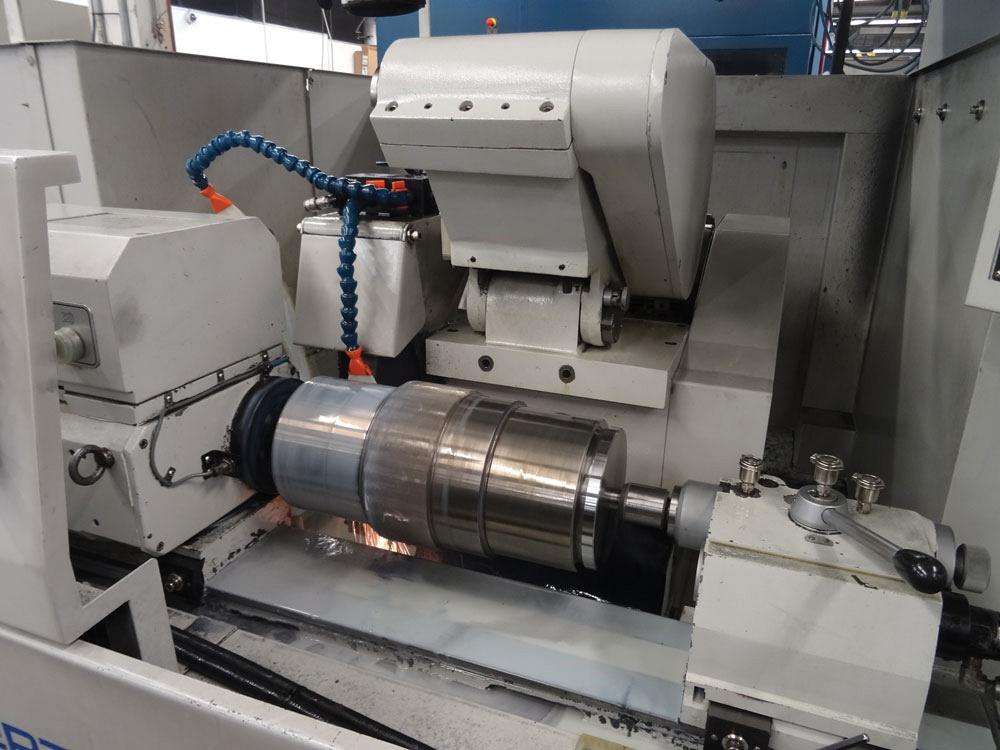

The company recently invested in a horizontal machining centre, which has allowed it to move out of the traditional vertical style it was used to. Chris noted that with this new machine, the company was able to take on new and unique projects it previously wasn’t able to undertake. In addition, NC Machine added an 8-in. through-the-spindle bore CNC lathe.

"We are always looking at equipment and trying to find machines and processes that are different from what we are used to," said Chris. "We want to be able to offer different options to our customers, and trends in equipment are constantly changing. So we are fighting to stay ahead of the curve."

Chris boasted that the shop also has a welding division and some fabrication. However, the company’s sweet spot is its machine shop. It has 15 CNC machines and 20 manual machines.

"The biggest challenge with adding new equipment is of course cost," said Dan. "Another challenge is all the planning that goes into effectively integrating new machines on the shop floor to ensure good work flow. We are currently looking to add one more robot dual-chuck lathe, which means we have to remove two to three machines in order to integrate it properly. It can be tough decision."

When Dan is exploring new equipment, service makes all the difference. Being located in Winnipeg, the company really works with only a few suppliers, and it is hesitant to work with companies in the east because of the lack of proximity to service. However, Dan has had a great working relationship with local dealers for larger distributors that focus on servicing the region.

Right now the shop is focused on maximizing the space for both manual and CNC machines and arranging the machines in a way that makes sense for work flow and efficient labour utilization. With only 14 to 15 workers, Dan explained that operators need to adjust and move quickly among multiple machines. Having more machines than people means that some machines will be idle sometimes. When machines get tied up, the shop can adapt and move to another machine to keep work flowing.

NC Machine & Tool founder Dan (left) and his son Chris Roche have grown the small Winnipeg-based shop into a 19,000-sq.-ft. facility with equipment ranging from milling machines to grinders and lathes.

"With the cost of labour being so high and with the challenge of finding skilled workers, we concentrate on making the best use of our workers and the efficiency of our shop floor," said Dan.

MANUAL MACHINES

Both Dan and Chris have been exploring purchasing new equipment, and in the past year the company as integrated new CNCs. However, Chris explained that NC Machine hasn’t moved away from the manual equipment because there is still a significant need for it on the shop floor, especially when it comes to specialized, custom jobs. The manual machines are also great tools for training new employees.

"Manual machines are great for one-offs and quick turnarounds," said Dan. "They are great for running jobs where we don’t need to run a program. We keep machinists and tool- and diemakers on staff to work on the manual machines as well as build complete assemblies. The manual machines allow us to modify, touch up, polish, and finish these parts. We have found, over the years, that it is much easier to turn a machinist or tool- and diemaker into a CNC setup operator than it is to train a CNC operator to be a machinist."

For the father and son duo, the challenge with integrating new equipment is that they need to strategize about what needs to be taken off the shop floor to make room for the new machine. Machines that aren’t being used efficiently are either sold or donated to local colleges.

Dan noted that, at the moment, they do have an excess of manual machines, but most are necessary to complete the jobs that are coming in the doors. The company also has good working relationships with surrounding CNC shops that reach out for help with manual work.

"Some small jobs just don’t make sense on a CNC or it’s not an economical choice," said Dan. "We’ve helped out other shops when needed, and as far as I can manage, we will always have manual machines on the floor."

EXPANDING REACH

In recent years the local market has really expanded globally. Chris noted that many of his local customers have been bought or integrated into large corporations with international reach. However, many of those customers have continued to work with NC Machine, so instead of dealing with the local branch, the shop is working with different divisions throughout the world, bringing in quite a few more projects.

Most customers supply their own drawings and NC Machine can take it from there. The shop generally works with tool and stainless steels, aluminum, as well as some plastics, trying to stay in the most requested materials. Chris sees little need to move into the exotics as he is focused on appealing to the widest customer base possible.

One of the biggest challenges the shop faces is staying competitive, especially in a market where customers are focused on getting the least expensive quote. It is also a challenge to find skilled workers. However, Chris credits his father’s support of apprenticeship programs with helping them through this. They take young, enthusiastic students and offer them hands-on training.

"Our employees are like family," said Chris. "We have a lot of long-term people here and we try and keep that small-shop, family-oriented mentality."

Associate Editor Lindsay Luminoso can be reached at lluminoso@canadianmetalworking.com.

NC Machine & Tool Co., www.ncmachine.ca

About the Author

Lindsay Luminoso

1154 Warden Avenue

Toronto, M1R 0A1 Canada

Lindsay Luminoso, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada

DiPaolo Machine Tools Open House 2024

- June 4 - 5, 2024

- Mississauga, ON Canada

FABTECH Canada

- June 11 - 13, 2024

- Toronto, ON Canada

Zoller Open House & Technology Days 2024

- June 12 - 13, 2024

- Ann Arbor, MI