- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Technology Spotlight: Complete machining system for mold makers

Metalworking fluid supplier, toolmaker, machine tool builder partner for unique system build

- By Canadian Metalworking

- March 2, 2022

- Article

- Metalworking

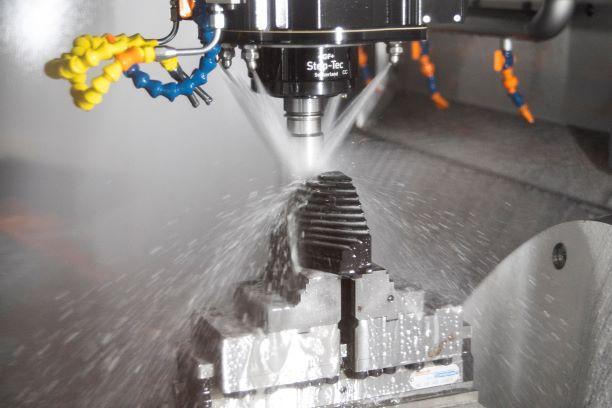

Testing of the system took place at the partners’ facilities, including here at the technology center of GF Machining Solutions in Biel, Switzerland.

GF Machining Solutions, Fraisa, and Blaser Swisslube have teamed up to develop the GR3 graphite machining system. Designed for wet-machining graphite operations, the system also can machine other materials on the same machine and even in the same setup.

The result is an efficient process that can achieve 0.005-mm tolerances while providing a healthier work environment and lower tooling costs, the companies report.

Wet instead of dry? It’s a paradigm shift in mold making. The entire process–from creating electrodes right through to the finished molds–now can be performed in a single setup.

“[It’s] a perfect interplay between machine, metalworking fluid, filtration, and tools,” said Marc Blaser, CEO of Blaser Swisslube. “The Blasogrind GTC 7 from Blaser is the ideal coolant for this application. It absorbs the graphite dust, thereby providing a much cleaner shop environment and healthier working conditions for machinists. It also optimally protects against tool wear.”

“The oil film reduces the degree of contact between the graphite and the tool surface, which further increases the service life of the tool. This technology offers outstanding advantages in the form of better component quality, fewer rejects, and significantly lower production costs,” said Dr. Dirk Kammermeier, head of product development at tool manufacturer Fraisa.

Costly multi-machine operation no longer is necessary for processing various electrode materials, and the associated labour from the setup of multiple processes also is eliminated.

Jonas Meier, head of the center of competence at machine builder GF Machining Solutions, said, “With the most recent innovation from GF Machining Solutions, we have not only solved the problem of dust build-up, but also [now] allow a single machine to be used for graphite, copper, and steel machining.”

All three of these materials can be machined in the same production system, without any manual intervention and with the same setup and tooling.

The system has been tested at Blaser Swisslube’s Technology Center in Switzerland, as well as in the metal cutting laboratories of Fraisa and GF Machining Solutions. A real-world component was simulated at all three sites during testing. In addition to the various tool coatings, numerous cutting oils were compared against one another during the rough cutting and finishing operations.

According to the builders, this system will give mold makers longer tool life, better part finishes, optimized cycle times, and substantial cost savings per machine per year.

Blaser Swisslube | www.blaser.com

FRAISA | www.fraisa.com

GF Machining Solutions | www.gfms.com

GR3 | gr3solution.com

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada