Marketing and Communications Manager

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Technology Spotlight: Large-gear grinding

Precision-shaped abrasive grain helps reduce grinding burn

- By Philipp Bötte

- August 25, 2023

- Article

- Metalworking

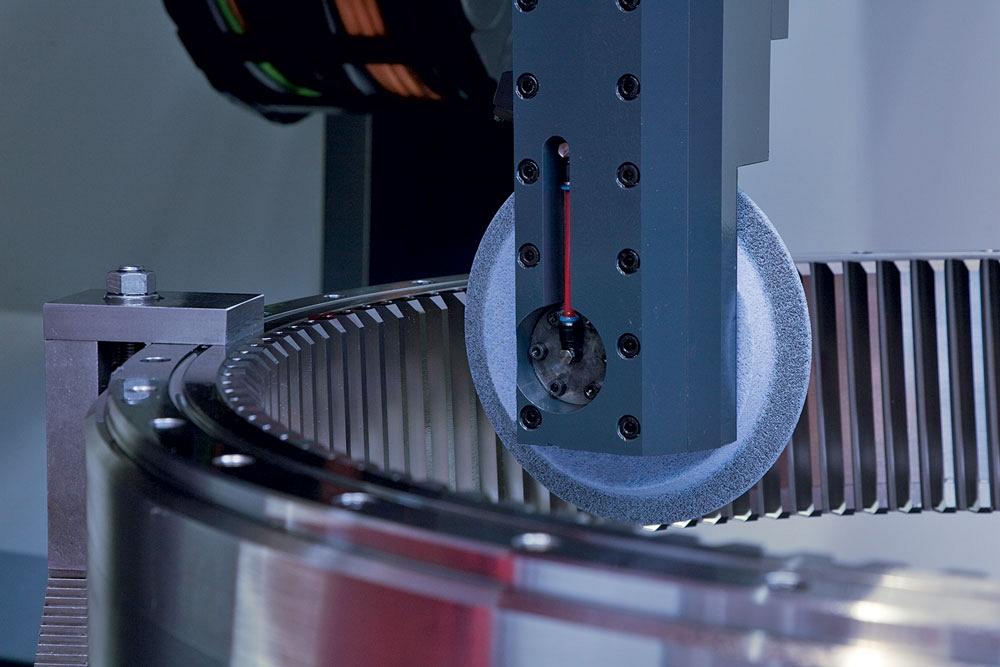

Synergy between the grinding machine, the grinding process, and the grinding wheel creates a productive environment capable of making high-quality gears. Images: Krebs & Riedel

Serial production of large gears requires a high level of quality and continuity during production, with emphasis placed on creating synergy between the grinding machine, the grinding process, and the grinding wheel.

Krebs & Riedel conducted several trials with its customers in their production facilities on different Klingelnberg Höfler RAPID grinding machines to test its new Blue Moon TZ grinding wheels. The company is well-known for its grinding machines and wheels and in the automotive and EV sector, but this family-owned manufacturer is now expanding into other sectors that also require large gears.

Creating Gears For Wind Power

In recent years, wind power has been an important factor in reducing CO2 emissions. Wind turbines are getting bigger and more powerful, but production costs need to be reduced. This requires production methods that can produce the gears cost-effectively and in high quality, even with complex flank modifications.

Gear sizes in the wind power sector typically range from 800 to 4,000 mm. Some gears can even reach a diameter of 8,000 mm and weigh up to 100 tonnes. The most common size in the field (of external gears) is 1,200 mm in diameter and ranges from module 12 to module 52. Module is a term used to define gear tooth size. Gears only will mesh if their teeth are the same module.

Grinding Wheel Power

By comparison, the profile grinding wheels typically have a diameter of 100 to 450 mm.As mentioned, synergy between the machine, the process, and the wheel is very important.

To help achieve this synergy, Krebs & Riedel developed the Blue Moon TZ wheel, which has a precision-shaped abrasive grain.

Only a perfectly ground gear geometry will ensure optimal power transmission for high wind turbine efficiency and smooth running. Also, grinding burn must be avoided because the forces in the gearbox are very high and breaking a tooth is very expensive.

High-precision gears have a longer service life, which helps reduce maintenance and production costs.

In trials, the new grinding wheel showed good cutting performance and a high material removal rate.

“In some trials, the material removal rate [Q'w or Q Prime] was more than 30 mm³/mms,” said Sigurd De Ridder, senior application engineer at Krebs & Riedel. “Precision-shaped abrasive grains are state of the art today. Blue Moon TZ is comparable in performance to other precision-shaped abrasive gains on the market. It is self-sharpening, very sharp-edged, microcrystalline, and has an elongated trapezoidal shape."

The wheel’s homogeneous pore structure also improves the entire cooling system during the grinding process. Because of its open structure, the entire grinding wheel is immediately flooded by the cooling liquid. Even using a high material removal rate, chips are transported away from the contact surface. This reduces the heat input that leads to thermal damage to the gear.

The wheels perform well in the grinding of planetary gears, spur gears, and IR outer and inner rings.

Grinding Test

On average, all tests on Klingelnberg Höfler RAPID 2500 machines had a cooler grind, longer tool life, and up to 20 per cent faster grinding time when compared to wheels without precision-shaped abrasive grain. The longer tool life and higher grinding performance helps reduce costs while achieving the same, or even better, quality of the gear.

Dressing tests performed by De Ridder on these setups showed on average a 20 per cent longer time between dressings and 30 per cent less required infeed, which also leads to a longer tool life of the dressing wheel. It also used less power.

The RAPID series profile grinding machines for large workpiece sizes are designed for component diameters up to 8,000 mm.

Depending on individual requirements, they are equipped with an extended stroke range (L variant). In addition to the standard configuration, the machine also is available with a small grinding head to accommodate small grinding wheel diameters of 300 to 20 mm (K variant).

In all configurations, these machines can be converted from external to internal gears in a short time by using optional internal gear grinding arms.

In addition, the arrangement of the machine axes helps create a thermally stable and almost vibration-free machine. The bed is made of mineral casting and the systems have wear-free torque drives in the machine table. The grinding head enables 5-axis grinding and has an integrated 3D probe. Adjustment of the helix angle during the grinding process creates gears that can be topologically modified in one-flank grinding or two-flank grinding.

Serial production of large gears requires many hours of workpiece setup, programming, grinding, dressing, and quality control. The dressing and grinding processes should be continuously optimized by application support.

Krebs & Riedel is available in Canada through Machine Tool Systems.

Philipp Bötte is marketing and communications manager for Krebs & Riedel, www.krebs-riedel.com, www.machinetoolsystems.com.

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI