- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

The untold benefits of upgrading your CMM

When upgrading may be your best option.

- By Canadian Metalworking

- April 19, 2013

Many companies are now choosing to upgrade their existing coordinate measuring machine rather than buying new and in most cases this is the most advisable thing to do. CMMs have not radically changed over the last 20 years; mechanically they remain basically the same. What has changed, however, is software, electronics and probing.

Cost Analysis: Retrofit vs. Purchasing New Equipment

The first step in deciding whether to retrofit your existing CMM or to purchase new or used is to examine the costs involved. As a general rule, if the retrofit is less than 65 per cent the cost of new, then a retrofit should be seriously considered; anything more than that, then other factors will need to be considered, specifically, the cost of removing old equipment and setting up new. The logistics of relocating the old system and installing the new can, on a very large machine, amount to many thousands of dollars. It’s a good idea to have an experienced CMM retrofit company look at your existing system and give an appraisal of the cost involved in bringing the machine to new status.

Software

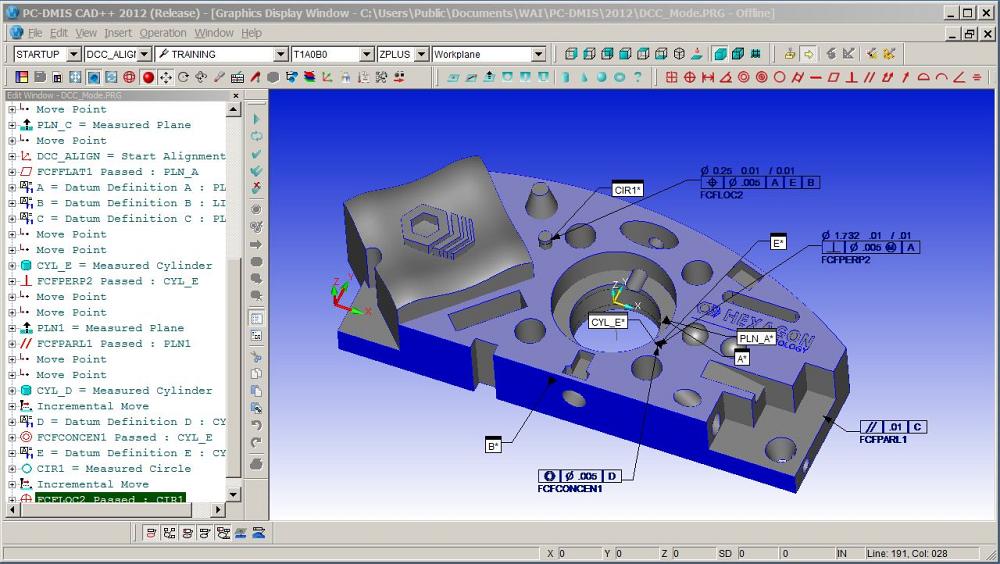

Software is the major reason most people upgrade their CMM. New products have the ability to read CAD, display results graphically and program off-line using virtual simulation. Many of the best-known software packages have the ability to work with older controls; notable amongst these is PC-DMIS, a software which has probably the widest interface capability with existing controllers.

In addition to its compatibility with CAD, these latest software releases will also be in compliance with the most current GD & T standards. North American and European GD & T standards have historically been revised every few years forcing software developers to incorporate these revisions into new releases.

Acquiring new software with CAD capability remains the primary rationale in the minds of those considering a CMM upgrade. With the installation of new software and all its capabilities, comes the transformation of an older, outdated machine into a new machine upgraded to current standards and compatible with modern CAD interfaces.

Controller

Generally speaking, machines that are over 7 to 10 years old also require a controller replacement. One way to be sure of this is to ask the manufacturer or the distributor of the product if replacement parts are available; if they are not available, then you have your answer. Remember, it's better to upgrade and update on your terms rather than placing yourself in a position where your machine will be down for several weeks. It's easier to negotiate terms and price when you are not under pressure to have the machine operational.

A new controller on an older machine can offer many benefits, primarily simplified electronics and easier maintenance. It's a common fact that components on older controllers generally cost more than the price of the new controller alone because the boards literally need to be reconditioned since they cannot be manufactured any more.

[gallery type="slideshow" ids="96107,96106"]

Probing:

Robotic Probe Heads

The next aspect you may need to look at is probing. If your current system has a fixed probe head, then you may want to upgrade to a robotic one. Robotic probe heads allow positioning anywhere on the part without the requirement to pre-build a probing cluster. This alone translates into a huge time savings and, of course, is much easier to program.

Touch Probing vs. Analogue Scanning

Should you stay with touch probing or should you look at an analogue scanning probe? There are benefits to each type:

Touch Trigger Probing (TTP)

Touch probe systems are more robust, easier to program and give excellent accuracy on the position of features. In fact, modular touch probes allow the use of change racks, making your CNC coordinate measuring machine run virtually automatically.

Analogue Probing

Analogue scanning probes can usually be considered when a new controller is installed on your older machine. It's important, therefore, to examine the benefits and drawbacks of these scanning systems.

Benefits:

- For sheet metal and plastic parts that require the collection of large amounts of data, scanning probes leave the touch probes in the dust since many hours of probing time can be saved.

- When looking at form on machined parts, nothing gives a better idea of shape and form deviation than a scanning probe.

- Most analogue scanning probes can also work as touch probes providing a huge advantage because the benefits of both systems are available to the user.

Drawbacks:

- The programming protocol is generally more elaborate than a touch probe, because there are more things to consider.

- Scanning heads are more likely to be affected by collisions as they do not have the built-in over travel of traditional touch probes.

- Price, of course, is also a factor, as scanning probes generally cost several times more than a traditional touch probe.

Summary:

Finally then, after selecting the level of upgrading you wish to do, you must compare this to the price of the new system. Generally speaking, the larger the CMM, the more cost-effective it is to consider an upgrade. Be sure to contact a reputable company that has extensive experience in CMM upgrades. Due diligence should also be performed on this company by contacting past recipients of upgrades and retrofits. All this will ensure your older coordinate measuring machine provides you with many more years of service, gives you confidence in the fact that you have a state-of-the-art coordinate measuring machine and, most importantly, saves you money.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

- Trending Articles

Automating additive manufacturing

CTMA launches another round of Career-Ready program

Collet chuck provides accuracy in small diameter cutting

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI