Tribology Specialist

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Every chip matters

Chip examination leads to better cutting fluid creation and, ultimately, better machining processes

- By Linus Meier, PhD

- March 7, 2023

The idea of capturing the machining process, chip formation, and the behaviour of metalworking fluid more precisely than ever before using photos and videos came about as part of a joint project between Blaser Swisslube and ETH Zurich.

Our R&D team used a high-speed camera with a macro lens placed behind a sight glass to keep the metalworking fluid at a distance to make uniquely sharp, precise recordings. They used a ring light to provide the necessary light intensity to capture the carbide cutter with a helix angle of 0 degrees that was specially ground for the test.

The results are fascinating. The high-speed recordings showed—for the first time—that the mechanism of action of the oil-free, water-soluble metalworking fluid [the team used Blaser Swisslube’s Synergy 735] improved lubrication even at high temperatures during machining and helped optimize milling processes. The fluid changed its properties and adapted to the machining process.

“This focus on all the details and the cooperation between our chemists and the machining experts enables us to develop metalworking fluids that improve processes sustainably, reduce production costs, and prolong tool life,” said Marc Blaser, CEO of Blaser Swisslube.

As the metalworking fluid used in the test cooled down, it became clear again, keeping the machine clean and allowing a good view of the machining process. The advantages also included a neutral odour and excellent skin compatibility. Flawless finishes are possible on materials including aluminum, titanium alloys, and CrNi steels. The minimal foaming means the coolant is also ideally suited to high-pressure systems.

The work was done in the Blaser Swisslube Technology Center, which has been undergoing continuous expansion for more than 10 years. At present, research is carried out using four CNC milling machines and a state-of-the-art grinding machine in a 16,146-sq.-ft. facility. New developments are tested and manufacturing production situations are simulated under realistic conditions. High-precision measuring devices and sensors enable the data acquired to be interpreted correctly.

Measuring Wear Reveals Savings

For example, a microscope camera for measuring wear automatically takes microscopic images of the turning plate every two minutes.

Tool wear often limits the economic viability of a process. The new measuring options give us meaningful information, directly from the machine. The optimized data flow means that changes to the metalworking fluid can be implemented more quickly and easily. High-performance metalworking fluids offer enormous savings potential in production, whether through increased productivity or reduced tool wear.

The perfect metalworking fluid often requires more than a dozen ingredients, including oils, emulsifiers, and additives. Producing a metalworking fluid to serve as a liquid tool that optimizes the efficiency of the entire production process requires both sophisticated formulations from our researchers and manufacturing expertise from our machining technologists.

We rely on the collaboration between both disciplines.

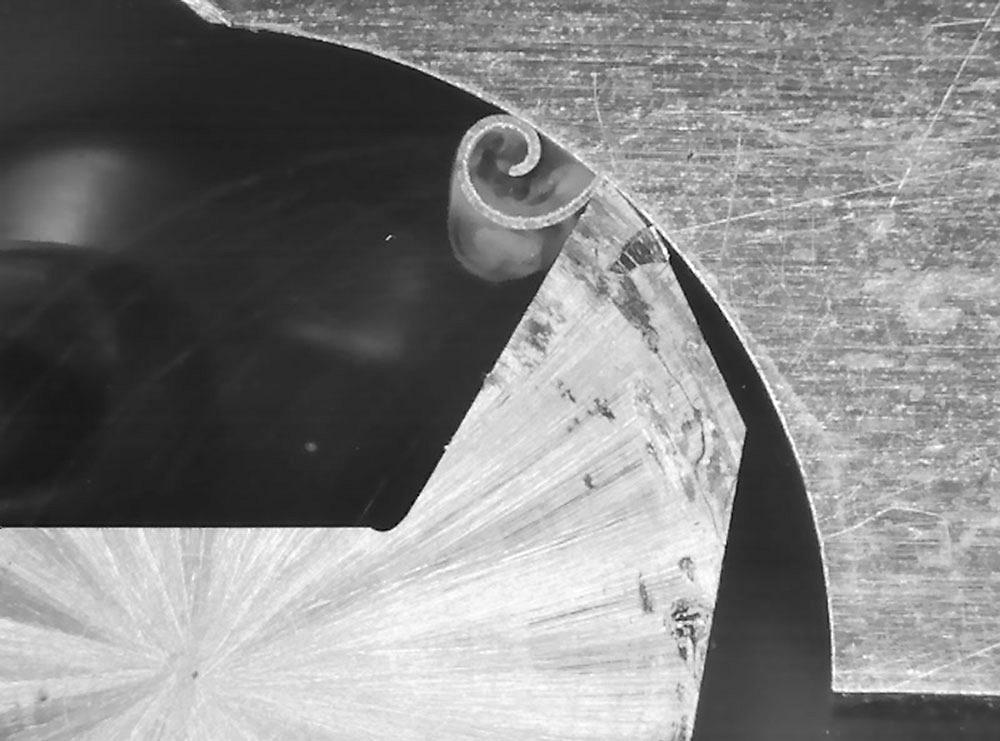

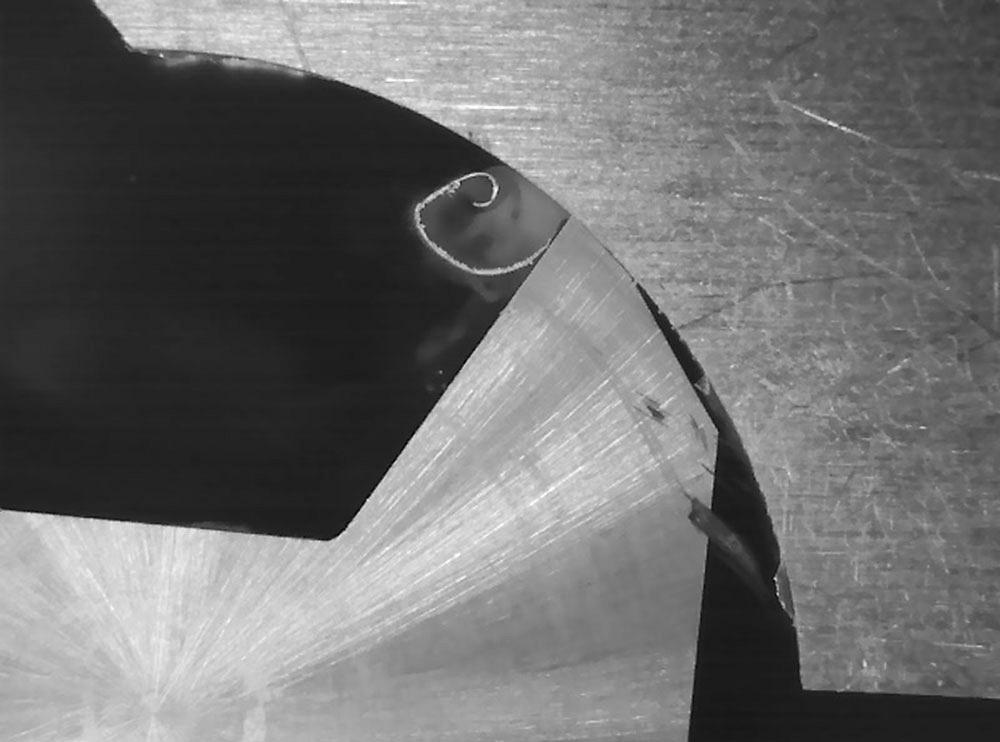

When machining titanium, the highest temperatures are reached near the cutting edge and in the chip. This is evident by a light-coloured cloud forming around the chip. Images: Blaser Swisslube

“Only if our specialist chemists are able to get to know the coolant on-site as part of a performance test, and then interpret the data acquired by the manufacturing technologists, are we able to make great progress in metalworking fluid development,” said Blaser.

Macro high-speed recordings are impressive. When viewed in slow motion, they show a carbide milling tool removing a perfectly shaped chip. The metalworking fluid should be seen around the curling chip–exactly where the heat is greatest. It should also leave an oil-like phase and form an even more effective lubricating emulsion.

Linus Meier, PhD, is a tribology specialist with Blaser Swisslube, 1 Hatfield Lane, Goshen, N.Y. 10924, 845-294-3200, www.blaser.com.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

Related Companies

- Industry Events

ZEISS Quality Innovation Days 2024

- April 15 - 19, 2024

Tube 2024

- April 15 - 19, 2024

- Düsseldorf, Germany

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada