- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

IDTEchEx report reveals how nickel is replacing cobalt in electric vehicles

- October 21, 2020

- News Release

- Management

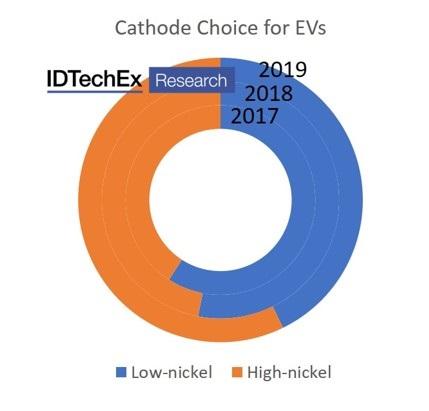

Historic data from IDTechEx shows a trend toward increasing amounts of high-nickel-content cathodes in electric vehicle batteries.

Electric vehicle (EV) powertrains are much more materially diverse than the internal combustion engines they replace. As a result, they are putting sudden and unprecedented strain on several raw materials industries.

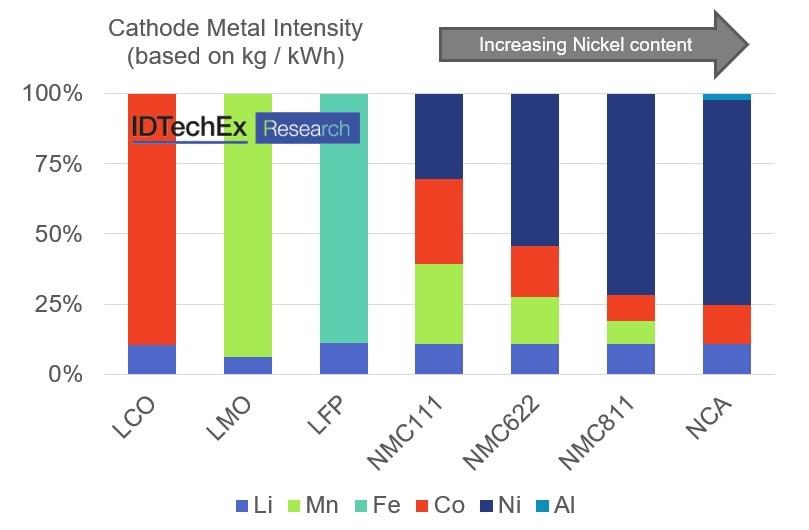

One of the most crucial materials is nickel, an essential part of the cathode in the lithium-ion batteries enabling electrification. Most automakers use nickel-based batteries for their balance of energy and power density: BMW, Hyundai, and Renault use variants of the lithium-nickel-manganese-cobalt oxide (NMC) chemistry, while Tesla uses a lithium-nickel-cobalt-aluminum oxide (NCA) chemistry. China also now favors NMC chemistries, having phased out lithium-iron-phosphate chemistries.

In 2019 more than 95% of new electric passenger cars sold used a variant of either NMC or NCA, as detailed in the new IDTechEx report, “Materials for Electric Vehicles 2020-2030.” Demand for nickel is further amplified by the trend toward higher nickel content in cells, as manufacturers switch to chemistries like NMC 622 or 811 over the previous 111 and 523 to improve energy density further and reduce dependence on cobalt.

Nickel is the most expensive material in EV batteries after cobalt and also is one of the most highly used outside of the battery industry. While nickel is not discussed as much as cobalt or lithium, sustainable and environmentally conscious supply is becoming more of an issue.

In 2017 the Philippines government suspended nearly half of its nickel mines, citing environmental concerns. Moreover, Indonesia accounts for the largest supply of nickel and in 2019 the country banned exports of raw nickel ore to boost its domestic processing industry. Indonesia also has the most planned developments for increasing nickel production and is set to dominate the supply chain.

Nickel typically is mined from ores that contain only a very small percentage of useful nickel, resulting in a large amount of waste material. Recently two nickel mining companies in Indonesia announced plans to use deep-sea disposal for the raw material waste into the Coral Triangle as they ramp up operations. Less than 20 nickel mines worldwide use deep-sea disposal, but these new facilities would account for millions of tons of waste material each year. This method typically is used because it is cheaper than the alternatives of dam storage or converting the raw materials to useful products.

Many automakers are aware of the environmental concerns in nickel supply and that it can undermine the environmentally friendly message of the EV. Most, including PSA, VW, and Tesla, have pledged to reduce the environmental impact of their batteries. This becomes challenging as the choice of suppliers that can meet the demands of these large automotive companies is limited. In the future nickel producers will have to prove that their practices are environmentally friendly if they want to sell into the European and American markets, where the automotive industry is making this a priority. Elon Musk has been quoted in Financial Times as saying that Tesla would give a “giant contract” to any companies that could mine nickel “efficiently and in an environmentally sensitive way.”

As the EV market grows with the trend toward higher-nickel chemistries, IDTechEx expects the demand for nickel from EV batteries to increase tenfold by 2030 compared to 2019. This makes the environmentally conscious supply of nickel a serious issue going forward for the EV market.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI