- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

TU Graz develops AM technology that uses LED light

- May 12, 2020

- News Release

- Metalworking

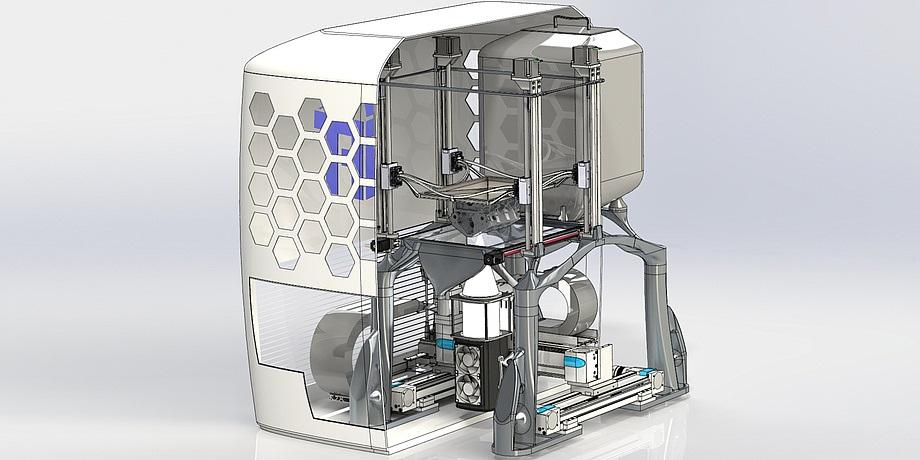

The 3D printer developed at TU Graz melts metal powder using LED light sources and processes it into components in AM. Photo courtesy of TU Graz.

A technology developed at Graz University of Technology (TU Graz) uses LED light sources instead of laser sources for the additive manufacturing of metal parts. Selective LED-based melting (SLEDM)—the targeted melting of metal powder using high-power LED light sources—is similar to selective laser melting (SLM) and electron beam melting (EBM), in which metal powder is melted by means of a laser or electron beam and built up into a component layer by layer.

Unlike SLM and EBM, however, the new process uses a high-power LED beam to melt the metal powder. It is equipped with a complex lens system by which the diameter of the LED focus can be easily changed between 0.05 and 20 mm during the melting process. This enables the melting of larger volumes per unit of time without having to dispense with filigree internal structures, thus reducing the production time of components for fuel cell or medical technology, for example, by a factor of 20 on average, the company states.

Read the full article here: www.tugraz.at/en/tu-graz/services/news-stories/tu-graz-news/singleview/article/led-statt-laser-oder-elektronenstrahl-neue-technologie-revolutioniert-3d-metalldruck0/

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI