- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Maximum turns: product report

Machine tools: turning product report

- June 3, 2011

- Product Release

- Metalworking

DMG

DMG’s CTX beta 1240 TC combines milling and turning technologies with an integrated disk magazine of 24 to 36 tools for fast tool exchange.

The machine features an integration of a controlled slide with a B axis milling spindle for five axis simultaneous machining.

X, Y and Z axis travels are 450 mm (17.7 in.), 100 mm (3.9 in.) and 1300 mm (51.2 in.) respectively. The 5000 rpm machine has a maximum turning length of 1250 mm (51 in.) and is equipped to handle part diameters of 450 mm (17.7 in.) with a bar capacity of 66 mm (2.6 in.).

Doosan Infracore

The Puma MX 2600ST combines a turning centre with a true machining centre, enabling the machining of complex geometries on a single machine in a single setup. This mill-turn is capable of producing parts up to 759.46 mm diameter (29.9 in.) by 1498 mm long (59 in.).

Powering the turning component is a 35 Hp, 4,000 rpm, high torque spindle motor. The motor is mounted on the headstock casting with the armature on the spindle O.D. This beltless design eliminates backlash, feedback error and vibration, resulting in longer tool life, less maintenance, high precision, and superior finishes. Driving the milling component is a 12,000 rpm, 30 Hp motor. Together, these two motors provide the muscle for heavy cuts in tough-to-machine materials.

The lower tool turret can accommodate live or static tools at any of its 12 stations, and be oriented toward either the main or sub-spindle. A 6.7 hp motor turns the live tools at speeds up to 4,000 rpm. The turret is non-lifting to protect the coupling from chips and other contaminants, and indexes station-to-station in 0.2 seconds. Milling tools are housed in a 40-tool ATC; an 80-station ATC is optional. Tool-to-tool change is 1.8 seconds.

The MX2600 combines a B axis (tilting) with Y axis to expand the number of geometries that can be machined without using customized rotary tool holders. It can cut, drill or tap above or below centerline, machine angular features, and provide a solid platform for heavy duty machining. A rigid, three piece curvic coupling locks at 5° increments, while the RGC provides extra rigidity in 0.001° increments.

Feeler

The Feeler HT-series high performance milling lathes, available in Canada from Methods Machine Tools, are offered in three configurations including an HT-30MC power milling turret machine, an HT-30Y model with a power milling turret and Y axis, and an HT-30SY machine featuring a power milling turret, Y axis and a sub-spindle.

Each HT-series lathe features a 3,500 rpm, 30 hp spindle with chuck diameter of 254 mm (10 in.) and bar capacity of 78 mm (3 in.). The HT-30SY also offers a 6,000 rpm, 15 hp sub-spindle with a 170 mm (6 in. chuck diameter and a bar capacity of 44 mm (1.7 in.). X axis travel is 178 mm + 82 mm (7 in. + 3.2 in.) and Z axis travel is 795 mm (31.3 in.) in each of the HT-series machines.

The HT-Series features a 30° slant bed with hand scraped slideway surfaces. Maximum turning diameter is 356 mm (14 in.) and maximum turning length is 705 mm (27.75 in.). A 12-position power turret with milling capability and Fanuc 18i-TB control are standard.

The FTC-series turning centres, including the FTC-150 and FTC-200L models, have linear guideways on the X and Z axis. The new machines feature 30° slant bed construction and a Fanuc 0i-TD control is standard.

The FTC-150 machine offers a 6,000 rpm, 15 hp spindle with a hydraulic chuck diameter of 170 mm (6 in.) and a bar capacity of 52 mm (2 in.). X axis travel is 150 mm + 20 mm (5.9 in. + .8 in.) and Z axis travel is 350 mm (13.8 in.). This turning centre includes a 10-station turret and offers a maximum turning diameter of 300 mm (11.8 in.) and a maximum turning length of 320 mm (12.6 in.).

The FTC-200L lathe features a 4,500 rpm, 25 hp spindle with a 8 in. (210 mm) hydraulic chuck diameter and 2.6 in. (65 mm) bar capacity. This machine offers a X axis travel of 175 mm + 25 mm (6.9 in. + 1 in.) and Z axis travel of 700 mm (27.6 in.). It includes a 12-station turret and offers a maximum turning diameter of 350 mm (13.8 in.) and a maximum turning length of 660 mm (26 in.).

The turning centres offer slant bed/boxway construction and include a Fanuc 0i-TD control and 12-station turret.

This series includes six models–FT-200A, FT250A, FT-350L, FT-350AL, FT-500 and FT-500XL. Spindles range from 5,000 rpm, 20 hp to 1,500 rpm, 50 hp motors and chuck diameter sizes from 8 in. (210 mm) up to 18 in. (450 mm). Bar capacity ranges from 65 mm (2.6 in.) to 162 mm (6.4 in.).

Maximum turning diameter is offered from 320 mm (12.6 in.) to 800 mm (31.5 in.) and maximum turning length from 500 mm (19.7 in.) to 3,006 mm (118.3 in.). X axis travel from 160 mm + 10 mm (6.3 in. + .4 in.) through 400 mm + 25 mm (15.7 in. + 1 in.) and Z axis travels from 540 mm (21.3 in,) to 3,100 mm (122 in.).

Hardinge

Hardinge’s new T‐42 Super-Precision and high performance turning centres are a replacement for the previous Conquest 42, Conquest T‐42, Quest 42 and RS Precision and Super-Precision machines.

The new T–series turning centers are what the company calls “the new benchmark in high precision, high performance turning.

The machines are available with features that include but are not limited to: live tooling with C axis, sub spindle, Y axis, main spindle parts catcher, and the company’s sub spindle parts catcher designed for removing delicate high precision parts with critical surface finish requirements without damage to the part.

MAG IAS

MAG’s full range of vertical turning centres in table sizes from 1000-8000 mm increase their versatility and cost effectiveness with the availability of Sandvik’s Coromant Capto C8 toolholding system.

“This industry-standard tooling system gives our customers the ability to more fully utilize their existing inventory of Coromant Capto tools, while increasing machine versatility with quick-changeover capability,” says Helene Nimmer, MAG global product leader. “The widely used Coromant Capto system gives owners of MAG VTCs the advantages of Sandvik’s decades of experience and R&D in turning and milling tools.”

The VTCs can automatically exchange Coromant Capto tools from either a standard disk tool changer or an expanded tool magazine. “The modularity of the Coromant Capto system also enables our customers to use a single system of standard tools and adapters for tools with different lengths and design characteristics that can be used in multiple applications and machines,” Nimmer adds.

“As the range of multi-processing capabilities on our VTC’s increases, the modular system of tools offers strong cost-control potential by allowing a broader range of work to be done without custom tools.”

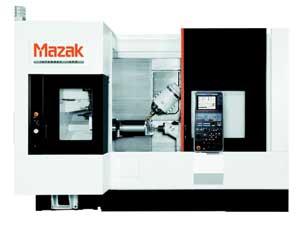

Mazak

The Integrex j-Series contains multiple models and falls in the middle of the spectrum of Mazak’s multi-tasking innovations. The j-400 performs four axis simultaneous machining with five axis tool tip positioning, providing significant advantages in productivity, accuracy and flexibility, says the company. Unlike multi-tasking machines with a drum turret type, Mazak’s j-400 accommodates 20 tools in a tool magazine (36 and 72-tool optional) and increases versatility in part production. The machine’s main turning spindle offers a maximum speed of 3,300 rpm.

The new machine also includes a 30 hp, 12,000 rpm milling spindle that can be indexed in 5º (or optional 1º) increments from –30º to 210º (B axis control), making it possible to perform outer diameter machining, as well as turning, facing, grooving and threading with the same flash tool. It also makes it possible to perform incline machining and all other conventional machining processes. The milling spindle can be radially indexed and clamped, enabling the same tool to be used for turning in forward and reverse directions.

The machine offers a maximum machining diameter and length of 500 mm (19.7 in.) with minimum tool interference for large workpieces. Its long axis strokes allow face milling, end milling and drilling to be performed above and below the centerline without C axis indexing. In addition, the true Y axis design allows for a larger machine envelope and tool reach, reduced interference and excellent chip evacuation when compared to conventional machines.

The new Mazak MX Hybrid Roller Guide system increases vibration dampening to extend tool life, handles higher load capacities, accelerates and decelerates quicker to shorten cycle times, consumes less oil for “Greener” operations, and lasts longer with less required maintenance.

Mazak’s Matrix Nexus CNC control allows for both conversational and EIA/ISO programming, and ensures easy programming for C axis, Y axis and angle machining.

Mori Seiki

Mori Seiki’s NTX 1000S high precision, high efficiency integrated mill-turn centre is designed for machining small precision parts for medical equipment and measuring instruments, which require complex machining. The NTX machines offer extensive features, including advanced thermal displacement compensation; a 40 per cent smaller footprint than previous models, and DMG/Mori Seiki original DDM, ORC and BMT technologies.

X, Y and Z axis travels are 380 mm (15 in.), 105 mm (4.1 in.) and 460 mm (18.1 in.) respectively. The 6000 rpm machine features a maximum turning length of 424 mm (16.6 in.) and a bar capacity of 52 mm (2 in.). Rapid traverse rates are 1,574.8 mm/m (40,000 ipm) for X axis, 1.574.8 mm/m (40,000 ipm) for Y axis and 1.968.5 mm/m (50,000 ipm) for Z axis.

Okuma

Okuma’s MacTurn 550 is a multi-function machine built to improve throughput and virtually eliminate fixturing for consistent quality and accuracy of your parts. Features include fast automatic tool exchange, variably configurable tool storage, a lower live turret, a multi function H1 upper turret and available nine axis machining/turning functions. The linear roller guide system combines the best of traditional linear ball guides and newer box systems, all supporting industry-competitive fast axis feeds. Standard on all MacTurn multi-task machines is the THINC-OSP control, a true open architecture control with expansive peripheral possibilities, plug and play capability, and Ethernet connectivity that allows use of third party software.

To go to related article click here.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI