- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Moi Composites introduces first 3D-printed fiberglass boat

- October 12, 2020

- Product Release

- Metalworking

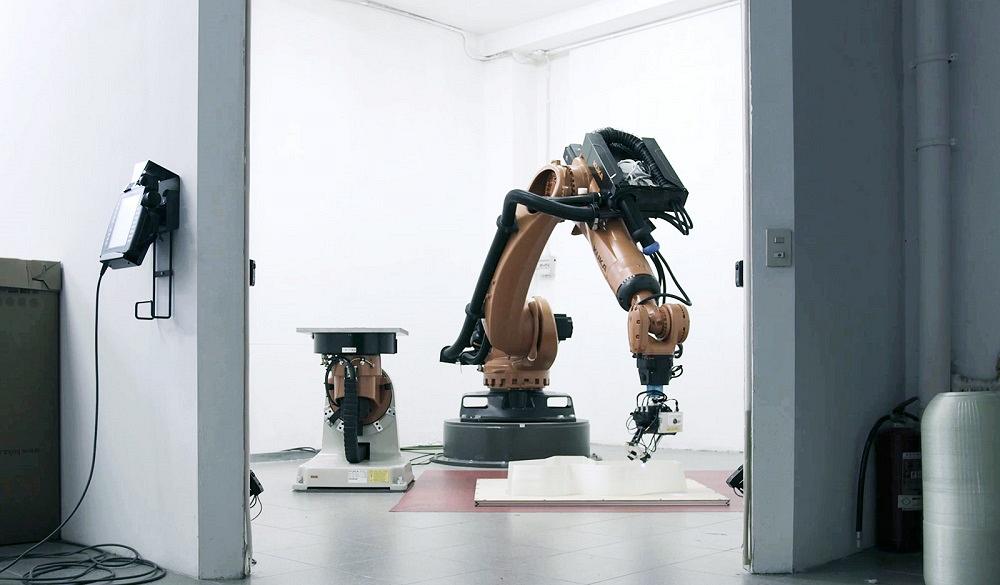

Moi Composites used robots guided by generative-design algorithms to 3D-print the 6.5- by 2.5-m boat MAMBO from a continuous-fiber composite.

Moi Composites has unveiled the completed MAMBO (Motor Additive Manufacturing Boat), which the company says is the world’s first real boat 3D-printed in continuous fiberglass thermoset material.

The boat was digitally crafted with patented Continuous Fiber Manufacturing (CFM), a system that uses robots guided by generative algorithms to deposit continuous fibers impregnated with thermosetting resin, starting from a 3D model of the object. This allows the creation of fiber-reinforced products with mechanical characteristics comparable to those of unidirectional fiberglass, without the aid of models, molds, and other tooling equipment. In this way, it is possible to obtain not only prototypes, but real products in small lots or unique pieces, efficiently and cost-effectively, the company reports. The process allows customization and high mechanical performance that is not available through traditional manufacturing. The material makes products durable and lightweight, and the robotic system allows for scalability in print size.

“We participated in the Genoa boat show in 2017, and it was during this event that we came up with the idea of making MAMBO. We saw the project take shape first, then brought it to life, and finally MAMBO arrived today at the sea. We have 3D-printed a boat, enhancing the concept of customization with a one-of-a-kind design created and tailored from the owner's mind, to give everyone the opportunity to understand and experience the sea in their own way. All this would not have happened without the support of our partners, who believed with us in this ambitious project,” said Gabriele Natale, CEO and co-founder of Moi Composites.

The boat spans 6.5 m long by 2.5 m wide; has a dry weight of approximately 800 kg; and is equipped with a real navigation system, cork flooring, white leather seats, and 115-cv engine. The various sections were printed using two Kuka Quantec robots at Moi Composites’ headquarters in Milan, Italy, and in Autodesk's Advanced Manufacturing Facility in Birmingham, U.K. The printed pieces were joined and laminated at Catmarine shipyard, creating a one-piece sandwich structure without hull-deck division. Moi’s partners in the project included Autodesk, Catmarine, Confindustria Nautica, Mercury Marine, MICAD, Osculati, and Owens Corning.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI