- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Logopress3 die design software upgraded with new features

- April 18, 2018

- Product Release

- Fabricating

Accurate Die Design Software Inc. offers the 2018 version of Logopress Corp.’s SolidWorks®-based Logopress3 die design software. This new version includes 16 pages of enhancements and new features.

The software now shows the actual slugs underneath the punches that will fall through the die openings. Once the strip layout is complete and the user is presented with the size of the strip and the tonnage required for the die, the designer can select which press the die will run in and choose from a family of tool templates that can be customized to fit the press. This provides standardization among users and allows new estimators and die designers to select the die parameters from a predefined database.

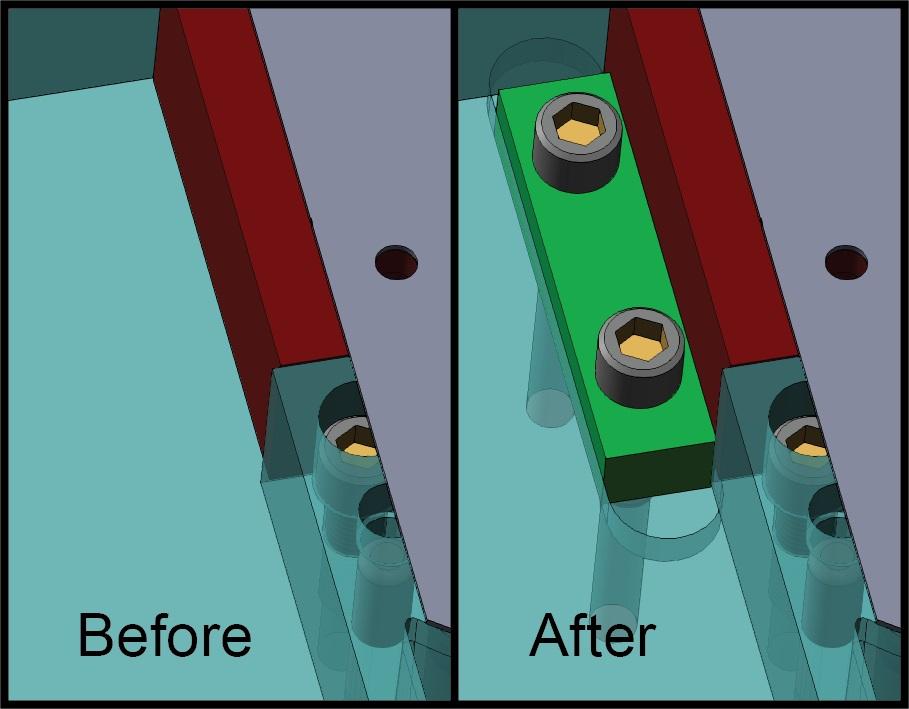

During die creation, the die designer can choose a predefined group of components from a database and insert them using the new Insert a Set of Components command. Not only does this insert this group of components along with all applicable fasteners and springs, it also creates all milled pockets, holes, and openings automatically—with a single mouse validation click.

Die simulation (die kinematics) and dynamic interference detection have been expanded to include not only dynamic interference, but also static interference. The simulation also now includes two new types of motion: traction and connecting rod/crank. These new motions are suitable for metal stamping using four-slide and vertical slide machines, as well as transfer dies.

In the bill of materials it now is possible to add an oversized machining allowance automatically to the finished dimensions of the stock size for ordering purposes.

Accurate Die Design Software Inc.

www.diedesignsoftware.comsubscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

CWB Group launches full-cycle assessment and training program

Achieving success with mechanized plasma cutting

3D laser tube cutting system available in 3, 4, or 5 kW

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

Welding system features four advanced MIG/MAG WeldModes

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI