- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

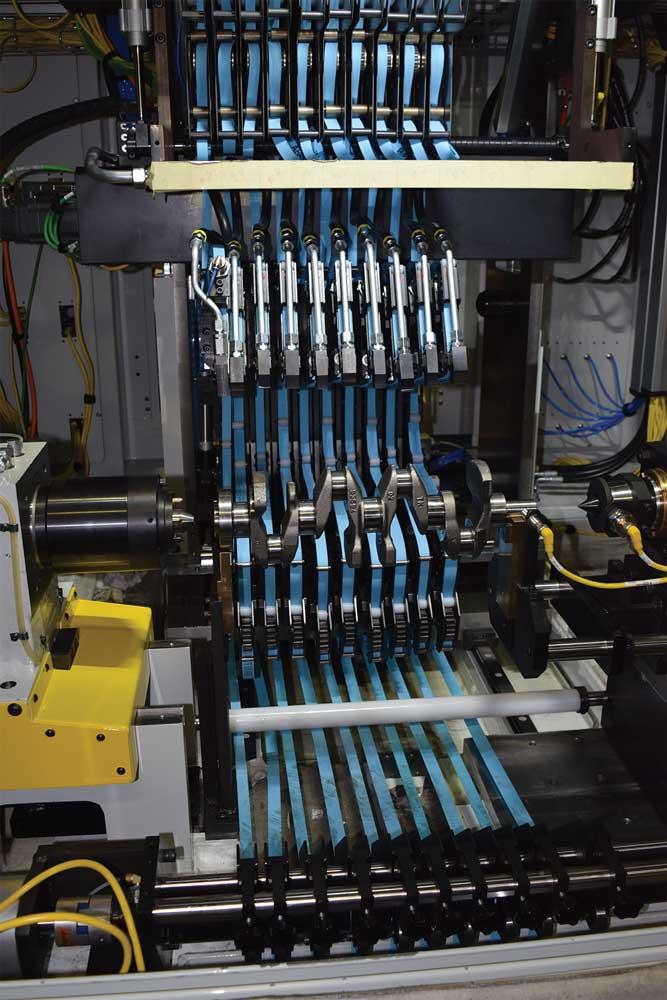

Industrial Metal Products’ Worldstar 1689 flexible microfinishing system polishes crankshaft parts

- March 15, 2018

- Product Release

- Metal Finishing

Industrial Metal Products Corp. (IMPCO) has introduced the Worldstar 1680 CNC microfinishing system for automatically polishing cylindrical bearing journals in crankshafts to micron tolerances without the need to manually change and reposition the tooling. This reduces changeover time from many hours to a few minutes, the company states.

Microfinishing removes microscopic amorphous surface material left from the grinding of a dimensionally finished part, such as a crankshaft, camshaft, or pump shaft, to permit a highly precise fit to a mating part.

In this machine, abrasive film is fed through a pair of opposed arms, each holding tooling that is shaped to fit over the part’s cylindrical bearing journals. During the process, the arms close around the journals, holding the film against the rotating part for a specified time to achieve the desired surface texture.

The part may undergo several increasingly fine levels of finishing to produce the final finish.

This polisher processes a four-cylinder crankshaft through three levels of microfinishing plus thrust face finishing. It can automatically position any of its 11 pairs of arms in any position to accommodate a range of crankshaft sizes.

Each microfinishing station in the four-machine system is loaded and unloaded automatically with an overhead gantry.

Industrial Metal Products Corp. * www.impco.com

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

BlueForge Alliance partners with Nuts, Bolts & Thingamajigs to develop Submarine Manufacturing Camps

Portable system becomes hot tech in heat treatment

Orbital tube welding webinar to be held April 23

Cidan Machinery Metal Expo 2024 to be held in Georgia May 1-2

Corrosion-inhibiting coating can be peeled off after use

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI