- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

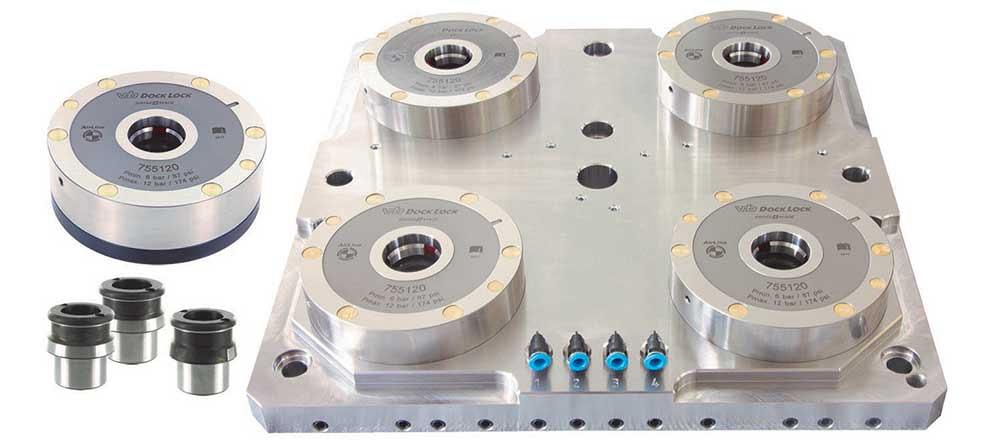

Kurt Mfg.'s DockLock Airline pneumatic clamping system creates three-surface lockdown

- February 14, 2018

- Product Release

- Metalworking

Kurt Mfg. Co.’s zero-point, pneumatic DockLock Airline system reduces setup time by more than 90 per cent by rapid changeout of large and small machine fixtures, the company states. This system features a tapered plug design to aid in positioning and clamping in one step even when the pallet has a slight tilt.

It uses a form-fitting clamping design with self-locking clamp segments and tapered plug design, which creates three-surface contact and lockdown force, pulling the plugs all the way into the cylinders. The system design helps prevent vibration and tilting.

The system uses 2,880 lbs. of pull-in force and 9,000 lbs. of retention force to hold the docking system in place.

It comprises flanged cylinders and tapered plugs that can be incorporated into a machine shop’s fixturing systems as needed, or they can be integrated into preconfigured base plates and pallets available from the company.

Additional standard features include air-blast cleaning to remove debris from the flange, mechanical clamp and air unclamping, and pallet monitoring ports for adding sensors.

Kurt Mfg. Co. * www.kurtworkholding.com

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI