- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Incorporating Next-generation IT Technology

Metal fabrication companies can improve operational control, profits with ERP system

- By Mark Humphlett

- November 9, 2012

- Article

- Automation and Software

Gaps in scheduling, inventory shortages, and configuration questions cause workforce inefficiencies and hold up time-sensitive shipments.

In the metal fabrication industry, complexity is exponentially becoming one of the most important challenges. And, of course, with any challenge, opportunities for success are also becoming abundant by incorporating next-generation technology into manufacturers’ IT strategies.

According to a recent IDC Manufacturing Insights survey, 71 percent of manufacturers expect market complexity to increase, and 61 percent expect operational complexity to increase as a result.1

To manage such complexity, metal fabricators’ need for a solid foundation of end-to-end business proficiency is essential. Just as important is utilizing next-generation enterprise resource planning (ERP) software, which enables metal fabrication companies to advance beyond the status quo of squeezing basic costs out of the business and into a much-needed growth phase.

The complexity metal fab companies face today can be leveraged into a dramatic market opportunity.

Controlling Financial Complexity

Most managers agree that complexity can be managed. Intricate processes can be planned, monitored, and streamlined. However, in today’s competitive landscape, leading companies are setting the bar higher. They are scrutinizing all profit-influencing variables, from workforce productivity to energy consumption of assets and facilities. No stone is left unturned when searching for wasted resources and chances to tighten processes into a precise synchronization of events and actions.

Every delay on the shop floor is recognized for its drain on profitability. Not only do gaps in scheduling, inventory shortages, and configuration questions cause workforce inefficiencies, they also hold up time-sensitive shipments.

Delays, errors, and miscommunications between departments can stretch order-fulfillment cycles. Top metal fab manufacturers understand the cost of such delays and work to identify and remedy the causes. Often it is the use of disparate systems, manual processes, outdated reporting, or the basic lack of system wide visibility that is the obstacle.

By using disparate systems manufacturers not only put customer satisfaction at risk, they also place a strain on receivables.

Slow delivery means delayed payment from customers—a significant problem for metal fab manufacturers who rely on healthy cash flow to maintain availability of raw materials—materials that come with highly fluctuating prices.

Improving operational efficiency and speeding processes, therefore, should be high priorities for profit-driven metal fab manufacturers. From the moment the order is received from the customer to the last mile of delivery, speeding the workflow means speeding the cash flow in the supply chain.

Profits are grown by meeting customer demands for an increasing variety of product configurations and higher levels of customization.

Increasing the speed at which fabricators do business means streamlining, standardizing, and expediting all processes.

For manufacturers, this means shortening cycles without taking shortcuts in strategic planning and quality control while collaborating more closely with customers—including using social media and community networks for sharing ideas, tracking discussions, and accessing shared files.

Additionally, it means using mobile devices to maintain continuous connectivity from anywhere, anytime, while improving visibility into processes and relevant contextual data for faster decision-making, as well as making the right investments to improve overall operational efficiency.

Utilizing Strategic Analysis

In addition to speeding processes, another way to control the financial complexity of the metal fabrication business is through better understanding of market demands. Enhanced planning, forecasting, and scheduling tools allow fabricated metal manufacturers to be strategically prepared for changing market conditions and evolving customer expectations.

In the past these companies typically have been distanced at the opposite end of the supply chain from the end user, making it difficult to obtain timely intelligence on the needs of the market. Therefore, response to product trends and market conditions has been slow, often leaving metal fab manufacturers with inventories and raw materials ill-matched to fill current orders.

Forward-looking companies have identified that previous weakness as an opportunity to solve a problem, create a competitive advantage, and surpass slow-moving competitors.

Advanced analytical tools provide the forecasting and demand planning information needed to stay in the forefront of changing conditions.

Of course, reporting tools and the ability to analyze real-time data play an important role in financial management of the company. Controlling costs, reducing waste, and improving cash flow are certainly important issues for most CFOs. For the metal fab industry, these are critical issues that have a high impact on already compressed margins. Monitoring bottom-line results on a ledger sheet is generally considered “too little, too late” by the executives who have successfully weathered the recent economic volatility.

Now, wizened industry leaders are considering detailed strategic analysis of each account to be a high priority. Big data analytics is a hot topic that is deserving of the current spotlight attention it is receiving.

Increasingly, metal fab companies are turning to these next-generation tools to optimize strategic planning and identify growth opportunities. While improved financial analytics help companies respond to economic challenges, there is still more that forward-thinking enterprises can do to take advantage of surfacing growth opportunities.

Adopt Customer-centric Product Development

Today business analysts tell us that mastering complex processes with customer-focused finesse and fiscal cost-effectiveness can set a company far apart from its competition. Although volatile pricing, reduced consumer spending, and thin margins are challenges, they also provide an opportunity.

Orders today seem to be anything but simple. Customers have high expectations and are looking to fabricators to manage new and changing configurations with speed and accuracy. In fact, for fabricated metal product manufacturers, much of the growing complexity they face stems from customers demanding a wider range of products, increased customization, and requirements for the production of entire systems, rather than just single items. This is forcing a more customer-centric product development process with project-based production and engineered-to-order systems to be managed.

To quickly adapt to these changes, manufacturers need to be flexible enough to manage and adjust rapidly to evolving customer requirements. Solutions should include product life cycle management (PLM) functionality that can easily manage the entire life cycle of products. In addition, having a tight link between engineering and manufacturing allows for streamlined production. Having the ability to quickly evaluate and implement product design changes allows companies to be agile and supportive of changing customer demands.

To grow business, many companies are looking for software that can help with the following:

- Collaboration. This increases efficiencies and speeds decision-making by giving customers direct access to the product development process.

- Configurability. Profits are grown by meeting customer demands for an increasing variety of product configurations and higher levels of customization.

- New-product development and introduction (NPDI). Consistently meeting customer demands by quickly developing and introducing new products with an end-to-end product life cycle process can be achieved.

- Quality management. Reducing time to market by ensuring product compliance and improving quality throughout production is a must.

- Integration. Tightly integrating engineering, sales, and production departments can improve the bidding and estimating process, increasing the number of customer orders that are obtained.

Drive Operational Excellence

Achieving operational excellence is the key to increasing the speed of business. According to IDC, however, many manufacturers experience barriers to attaining such efficiencies.2

In particular, an inability to rapidly adapt to business process change is ranked as the top barrier, among a number of issues that contribute to a slower pace of business. This also highlights that manufacturers aren’t as agile and responsive as they need to be.

IDC reports that manufacturers identify the following as the top barriers to improving operational excellence:

- Inability to rapidly adapt business processes to change.

- Ineffective or inadequate IT systems.

- Lack of accurate and timely information.

- Mismanagement of complex manufacturing operations.

- Difficulty in collaborating with suppliers, trading partners, and customers.

- Inavailability of skilled resources.

- Lack of funds to implement changes.

- Inability to consistently deliver on time.

- Inability to accurately predict customer demand.

- Insufficient management of complex global supply chains.

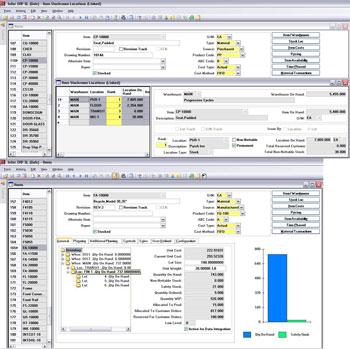

According to the study, ineffective or inadequate IT systems are ranked as the second-most common barrier to achieving operational excellence. Manufacturers that have ERP systems typically use them to focus primarily on financial and back-office functionality. What these generic, transactional ERP systems lack is the ability to properly plan or schedule for a mixed-mode manufacturing company and manage critical manufacturing areas such as punching, cutting, bending, stamping, forming, and finishing.

Metal fabrication manufacturers are learning that handling the many complexities requires a system that also supports other critical areas of the business, such as product life cycle management, customer order management, quality management, and supply chain management—processes that all influence profitability of fabricated metal products.

By incorporating next-generation technology into their IT strategies, companies can take advantage of evolving opportunities and turn complex market challenges into competitive advantages.

Notes

1. Pierfrancesco Manenti, “In Pursuit of Operational Excellence: Accelerating Business Change Through Next-Generation ERP (IDCWP47T),” IDC Manufacturing Insights, January 2012, p. 6.

2. Ibid. p. 9.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada