- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Robotic Welding With Adaptive and Autonomous Principles

Reduce programming time, eliminate manual intervention with advanced robotic welding techniques

- By Kevin McWhirter

- August 22, 2013

- Article

- Welding

An autonomous robot has the capability to adapt to changes in the real world and guide itself with no control from an operator.

Automating your welding process can provide many benefits, such as improving overall quality, increasing productivity, reducing overall welding costs by eliminating overwelding, decreasing proc-essing times, and removing the welder from the welding fumes.

Although all robotic welding applications have their challenges, robotically welding components for heavy equipment presents unique challenges compared to the traditional applications for which robots are more commonly used.

Large sections often require multipass welding as well as preheat and interpass temperature control to maintain quality.

They also generally have large variations in fit-up, and it is often not feasible to fixture them for welding in the same manner you would smaller components. In addition to these challenges, the part volumes for heavy equipment manufacturers are usually low, which requires the system to have the ability to process many different parts to make it feasible for automation.

Although it seems there are many obstacles to overcome, with the right approach, you can tackle each of them with the technology available today.

Preheat and Interpass Temperature Control

Preheating a component that will be welded by a robot poses a number of challenges.

If preheating is performed in the robotic welding fixture, the robot cannot run, so productivity suffers. If preheating is done outside of the robotic work area, the robot can work on other tasks, but the part will be loaded into the fixture hot. This can be uncomfortable and dangerous for personnel. In this scenario, part cooling also might be a problem if the timing is not perfect and the part has to wait too long for the robot to finish previous tasks.

If the welding cycle takes a long time, part cooling becomes a factor, and it is likely that the operator will have to enter the cell with the rosebud torch to bring the part back up to temperature. Anytime the robot is stopped during the cycle, the part will continue to cool.

Regardless of the scenario, with manual preheating, the part temperature is never truly known unless the robot is stopped frequently and the operator takes measurements during the cycle. This means frequent stopping of the robot cell to check part temperature and the likelihood of having to bring the preheat torch in every time the temperature drops below a certain threshold.

In a multipass application, the operator probably would have to enter the robot cell between every layer to check the temperature and, if required, reheat the part to maintain proper interpass temperatures.

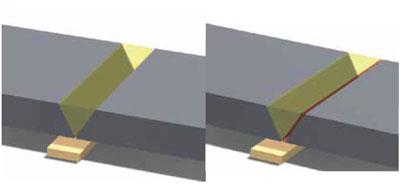

Figure 1: The joint on the right shows a root opening difference of 3 mm compared to the joint on the left. The red layer in the illustration on the right is the weld volume difference between the joints, which has to be compensated for. Note: The weld reinforcement (weld cap) is not shown; however, this volume also must be accounted for.

These processes place burdens on personnel during the entire welding cycle, requiring the operator to pay close attention to the timing of the process so that preheat can be done as quickly as possible to minimize the heat loss in the part.

If the part is not heated properly, poor quality is the likely result.

Although these are major challenges, recent developments can overcome them by allowing fabricators to fully automate the preheat and interpass heating processes to improve productivity and quality.

The robot automatically switches between welding and preheat and will heat the part only when required. Continuous measurement cycles also are taken throughout the welding process. If the robot stops for any reason and the part cools, the robot will automatically reheat the part back up to the welding temperature prior to welding.

Robotic preheat and interpass temperature control now can be fully integrated into the robotic welding process to provide a seamless sequence between preheat, welding, and interpass temperature regulation.

The result is an even distribution of heat throughout the part with a consistent control of temperature that is maintained during the entire welding process. This is accomplished completely without manual intervention.

Addressing the Fit-up Challenges

Fit-up of heavy fabrications provides its own challenges, but fabrications with groove welds often add to the difficulties because of variations in the weld joints from part to part. Small changes in fit-up result in large changes in the weld volume required to fill the joint properly.

When performing the groove welds by hand, the welder can slow down and speed up as required to fill the groove adequately. However, in a robotic process, the parameters are fixed and do not change from part to part.

The robot’s ability to automatically adjust the weld parameters to changes in the joint geometry is known as adaptive welding.

In adaptive welding, the weld groove volume is input so that the robot can make intelligent decisions on how to facilitate changes in weld parameters (see Figure 1).

The volume data for adaptive welding can be collected with various tools, including optical sensors and mechanical probes. Each of these tools has its own advantages and disadvantages and must be selected carefully for the application.

The adaptive welding concept is by no means new; however, new developments in the adaptive welding process are continually being made.

One recent development in adaptive welding is combining the use of specialized searching algorithms with the tools available in the robot for mechanical sensing of the part. These searching algorithms allow the robot to determine the exact position of the joint and also calculate the required weld volume.

Corrections to welding parameters are then applied by a specialized adaptive algorithm.

In this application, mechanical sensing provides a repeatable method for finding the root of the groove and measuring the joint volume. Because of the amount of searching required, a specialized searching probe was also developed to improve the repeatability of the search.

This concept is economical, highly flexible, and can be applied to numerous applications.

Traditional Programming Style

Traditional robot programming requires moving the robot to multiple positions and recording those positions in the robot’s teach pendant, point by point. The robot program becomes a series of points in space and when played back, and the robot moves sequentially through each motion instruction until the program is complete (see Figure 2).

To complete real-world tasks, other commands, such as arc welding instructions, are mixed in between the motion instructions that direct the robot on how to carry out that task (see Figure 3).

This type of programming, known as point programming, is the most basic form of robot programming. It is most commonly used for day-to-day production. In this type of setup, the robot simply repeats exactly what it performed on the prior task without variation.

Point programming generally is fixed for a certain part, and when new parts are to be added, a new program is created and the point-teaching process is repeated. If there are 20 different parts to be welded, 20 different programs are created.

Such a program is very easy and quick to create; however, there is little intelligence and no adaptation to part variations. And, if it is necessary to program all of the parts in a complete product line, many hours of programming are required to initially create and debug each program. Then, many more hours are required to maintain those programs after they are created. This becomes a very time-consuming process and makes the payback longer, especially for companies with low-volume production.

Autonomously Processing Parts

It is widely accepted that the true future of automation is the autonomous robot. An autonomous robot has the capability to adapt to changes in the real world and guide itself with no control from an operator.

Science fiction movies and novels have fantasized about this for years, and some companies today have products that provide some level of autonomy for certain functions.

One recent development is the welding of a complete product range using the principles of autonomous welding.

As an example, consider a product family that consists of a large quantity of part numbers, and each part varies in size intervals of 1⁄4 in. This creates a huge challenge if the entire product line is programmed using traditional methods.

This product family can instead be set up in an autonomous welding system, with the robot determining the geometry of the part placed in the welding fixture and then calculating the entire welding and preheating path. In addition, the robot autonomously searches each weld joint and calculates the weld volume.

Processing parts using autonomous principles means that the complete product line can be welded without each part being individually programmed. A lot of programming time is saved, and adding new parts can be done easily because the algorithms are based on part geometry. Program memory space is saved as well.

Certain geometric principles have to apply in the part family to process parts this way, and the predictability of the part models must be dependent on part geometry. If this is not the case, user input is required for processing.

Although fabricators that weld large fabrications have a number of challenges to make robotics feasible, these challenges are not insurmountable. As long as the application is approached in the right way from the beginning, success can be achieved.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI